Process and system for treatment of ceramic processing wastewater

A technology for wastewater treatment and ceramic processing, applied in ceramic wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

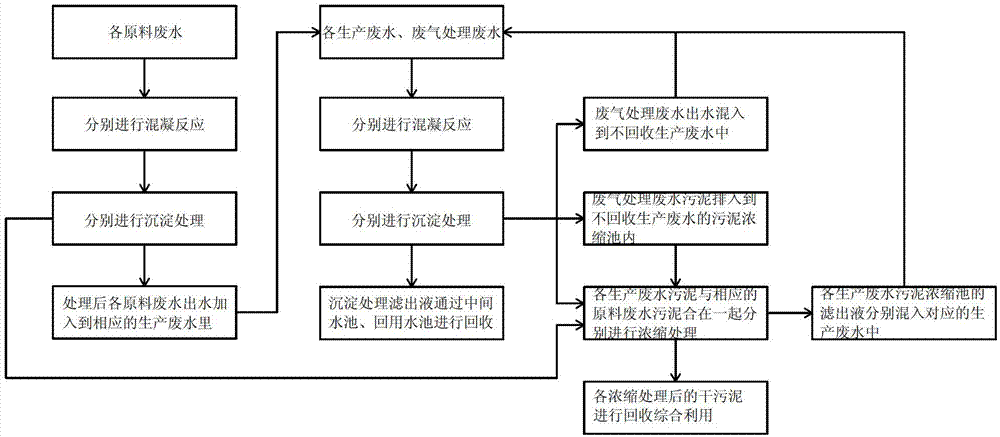

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

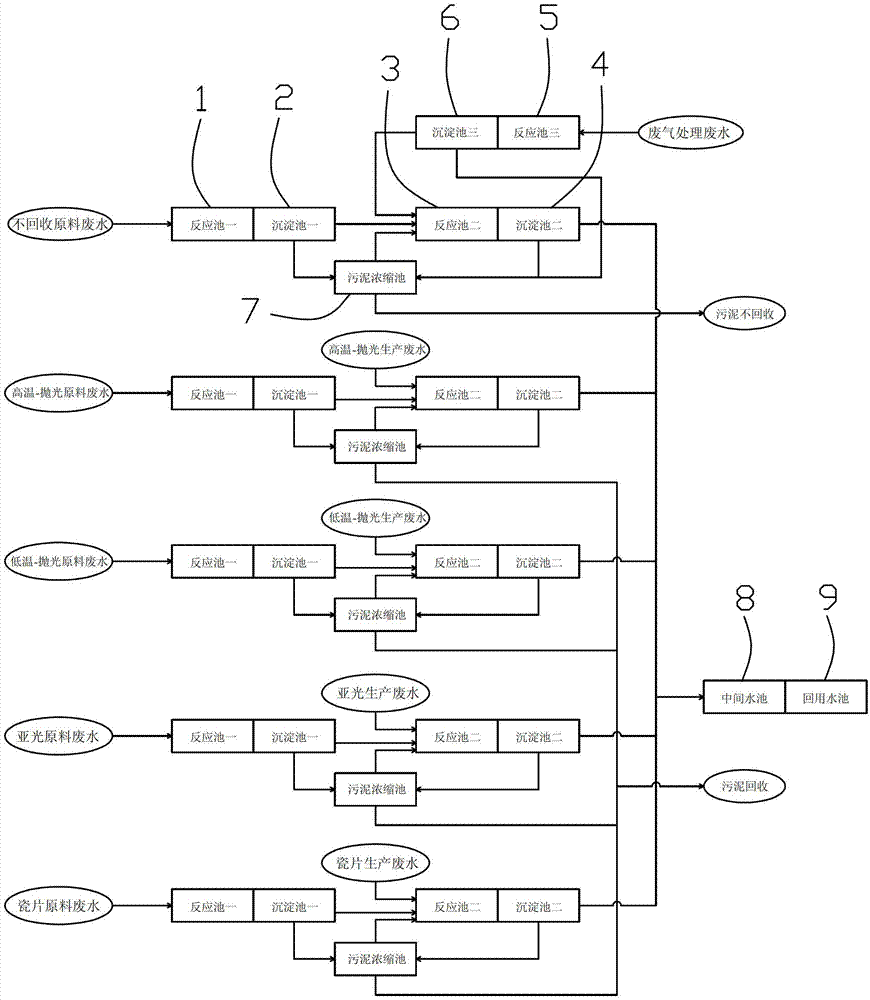

[0023] This embodiment is a ceramic processing wastewater treatment system, which has a first treatment zone, a second treatment zone, a sludge concentration treatment zone, and a recovery zone. In this embodiment, the classified collection of 11 types of wastewater is taken as an example. The wastewater is sludge non-recycling production wastewater, high-temperature-polishing production wastewater, low-temperature-polishing production wastewater, matt production wastewater, ceramic tile production wastewater, and corresponding wastewater. Mud does not recycle raw material wastewater, high temperature-polishing raw material wastewater, low temperature-polishing raw material wastewater, matte raw material wastewater, ceramic chip raw material wastewater, waste gas treatment wastewater.

[0024] The first treatment zone includes 5 reaction tanks-1 for treating raw material wastewater, respectively corresponding to collecting sludge without recycling raw material wastewater, high tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com