Surface quenching method of hot straightening roll

A thermal straightening roller and surface quenching technology, which is applied in the field of heat treatment, can solve the problems of coarse structure, high energy consumption, and limited use, and achieve the effects of sufficient austenification time, low frequency energy consumption, and increased specific power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

[0013] The manufacturing method of the thermal straightening roll of the present embodiment has the following steps:

[0014] ①Preparation and conditioning of billet rolls.

[0015] In view of the complex working conditions of the hot straightening roll, high accident resistance and wear resistance are required, so H13 hot work die steel is selected as its material to prepare the billet roll.

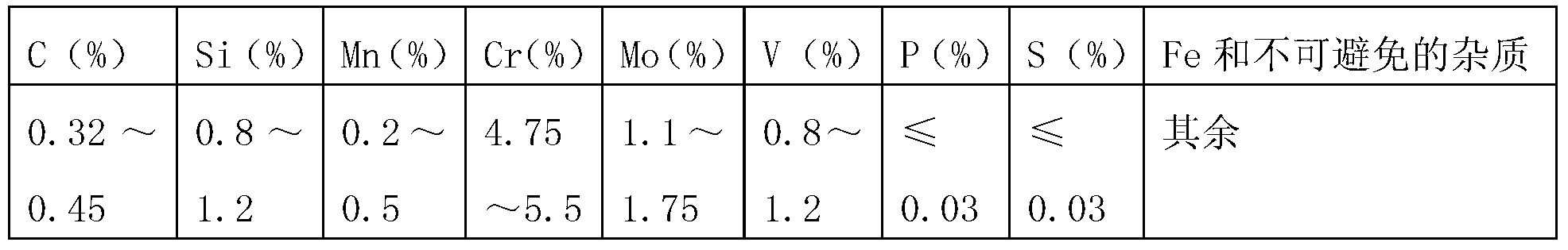

[0016] H13 hot work die steel is 4Cr5MoSiV1, its chemical composition is shown in Table 1.

[0017] Table 1

[0018]

[0019] .

[0020] The rough-ground billet roll is quenched and tempered in a well-type furnace to reduce bending deformation.

[0021] ②Surface quenching treatment.

[0022] The intermediate frequency induction quenching in the dual-frequency quenching inductor is adopted, the frequency is 200-250Hz, the height of the inductor coil is set to 80mm, and the quenching temperature is 1100-1110°C.

[0023] After quenching, the roll is sprayed with water to cool first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com