Isothermal compression type heat engine

A heat engine and isothermal compression technology, which is applied to hot gas variable capacity engine devices, engine components, combustion engines, etc., can solve the problems of low heat engine efficiency, low utilization efficiency, and low exhaust heat recovery rate of heat engines, and achieves high efficiency. Working pressure, the effect of improving the efficiency of the heat engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

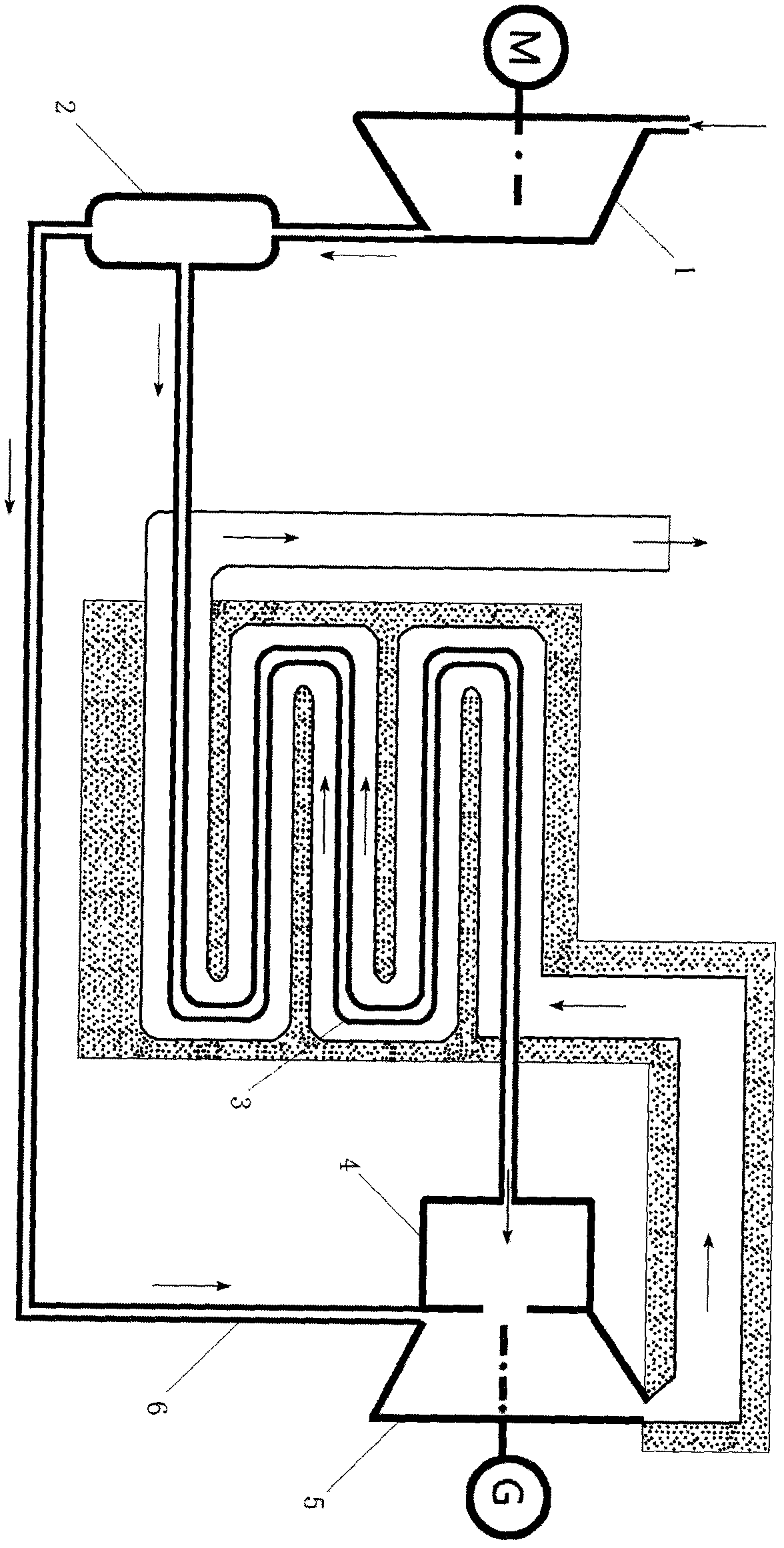

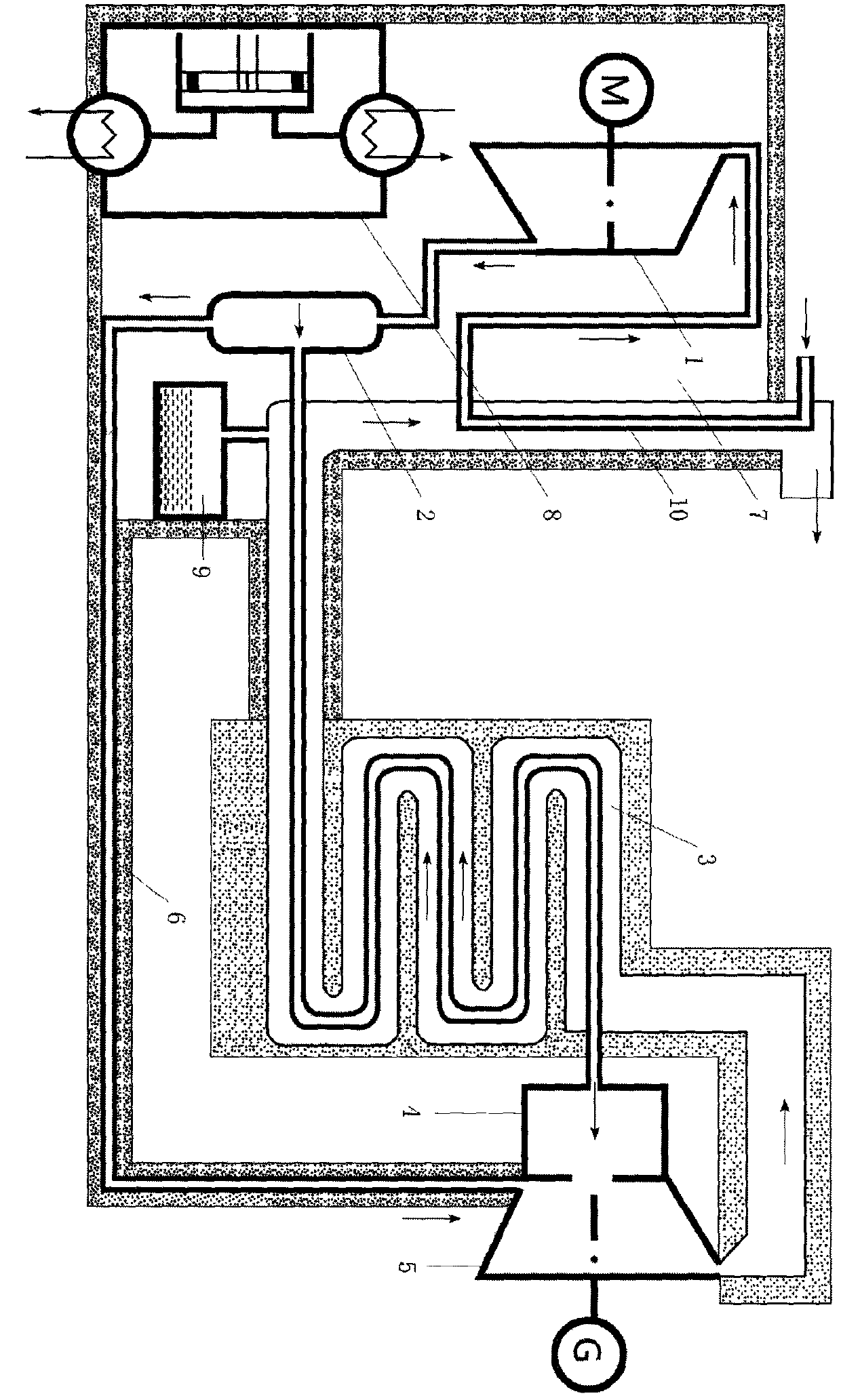

[0030] See figure 1 , The operating procedure of the isothermal compression heat engine device under normal temperature environment conditions of the present invention is as follows:

[0031] 1. Start the isothermal air compressor 1 , Isothermal air compressor 1 Inhale normal temperature and normal pressure air from the natural normal temperature environment and apply multi-stage isothermal compression to it, isothermal air compressor 1 The heat generated in the compression process is discharged to the natural room temperature environment, and then the room temperature and pressure air is compressed into room temperature and high pressure air, and it is injected into the heat preservation high pressure air storage tank 2 .

[0032] 2. The room temperature and high pressure air is supplied from the heat preservation and high pressure air storage tank 2 Enter the insulation composite pipe 3 The inner tube and then into the combustion chamber 4 , It burns with fuel in the combustion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com