Waste heat recycling device for engine oil of automobile

A technology of waste heat recovery and engine oil, which is applied in the direction of fuel heat treatment device, engine lubrication, engine start, etc., can solve problems such as instability, discontinuous and uncertain guide oil waste heat, etc., to prolong life, increase temperature, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

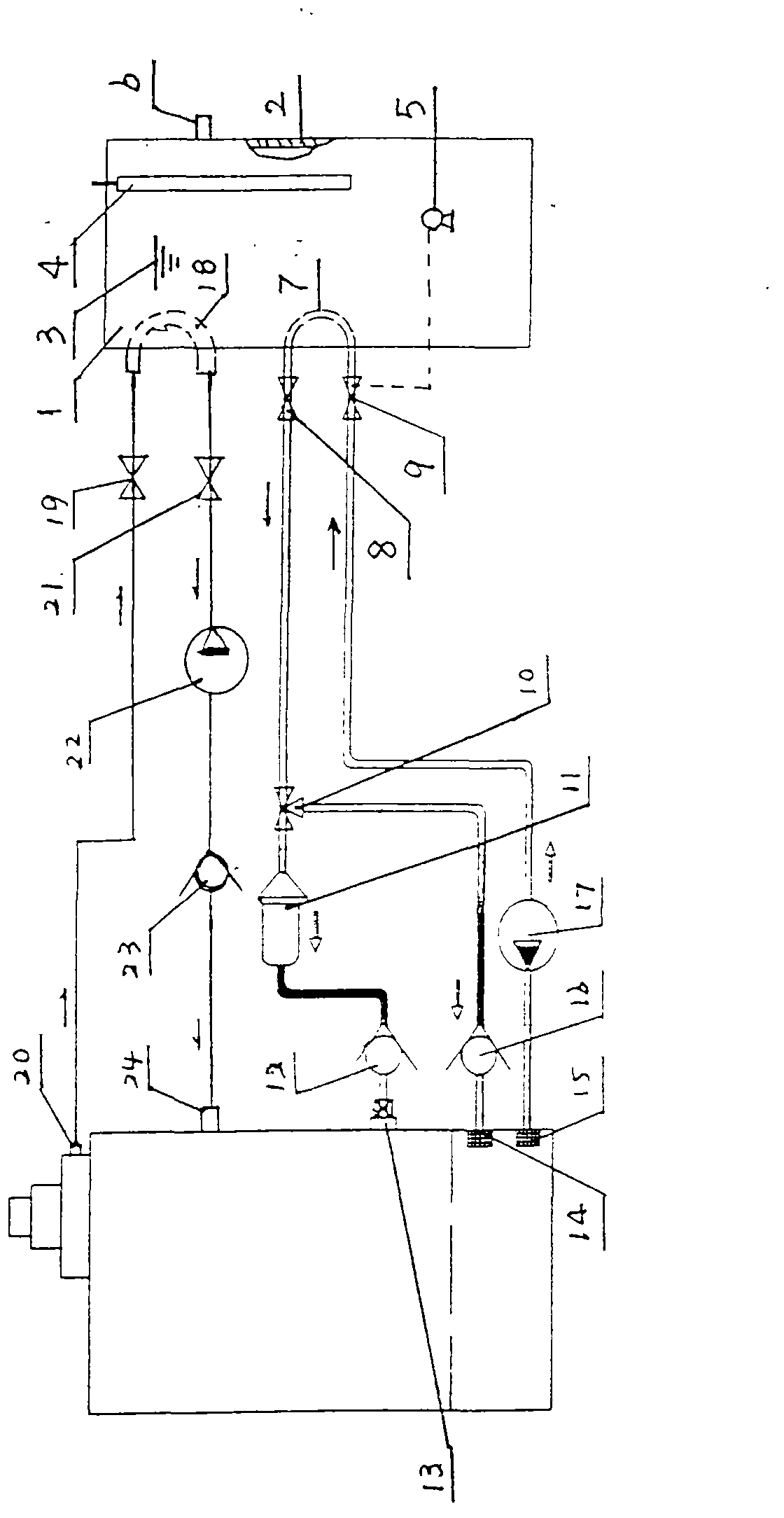

[0012] Further detailed description in conjunction with the accompanying drawings; the arrows in the figure show the direction of fluid medium flow;

[0013] Such as figure 1 As shown, the waste heat recovery and utilization device of automobile engine oil has a heat storage and heat exchanger with external heat preservation, heat transfer of heat-conducting working medium, circulation pipeline and control system, and the specific structure of the heat storage and heat exchanger 1 is as follows: The shell 2 is filled with phase-change heat storage material 3 for storing heat and supplying heat to the outside, and is equipped with a temperature sensor 5 with an interlocking mechanism, and is also equipped with a heat exchange unit inside, and each heat exchange unit is separately There are inlets and outlets connected to the shell 2, and the heat-conducting working medium in each heat-exchanging unit can circulate in the corresponding heat-exchanging unit through its correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com