Electromagnetic-drive electrostatic-detection bulk acoustic wave harmonic-vibration triaxial microgyroscope and preparation method thereof

An electrostatic detection and electromagnetic drive technology, applied in the field of micro-gyroscopes, can solve problems such as low signal sensitivity, increased processing complexity, and impact on device performance, and achieve the effects of simple manufacturing process, high yield, and good symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

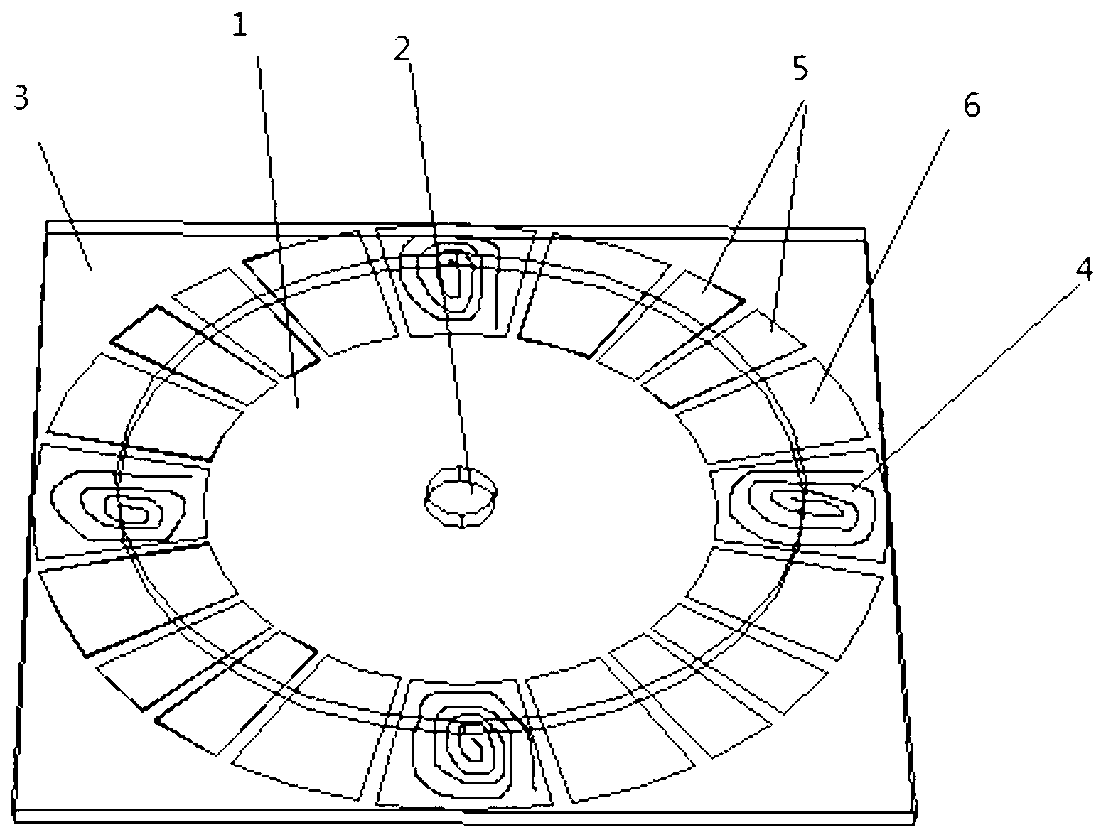

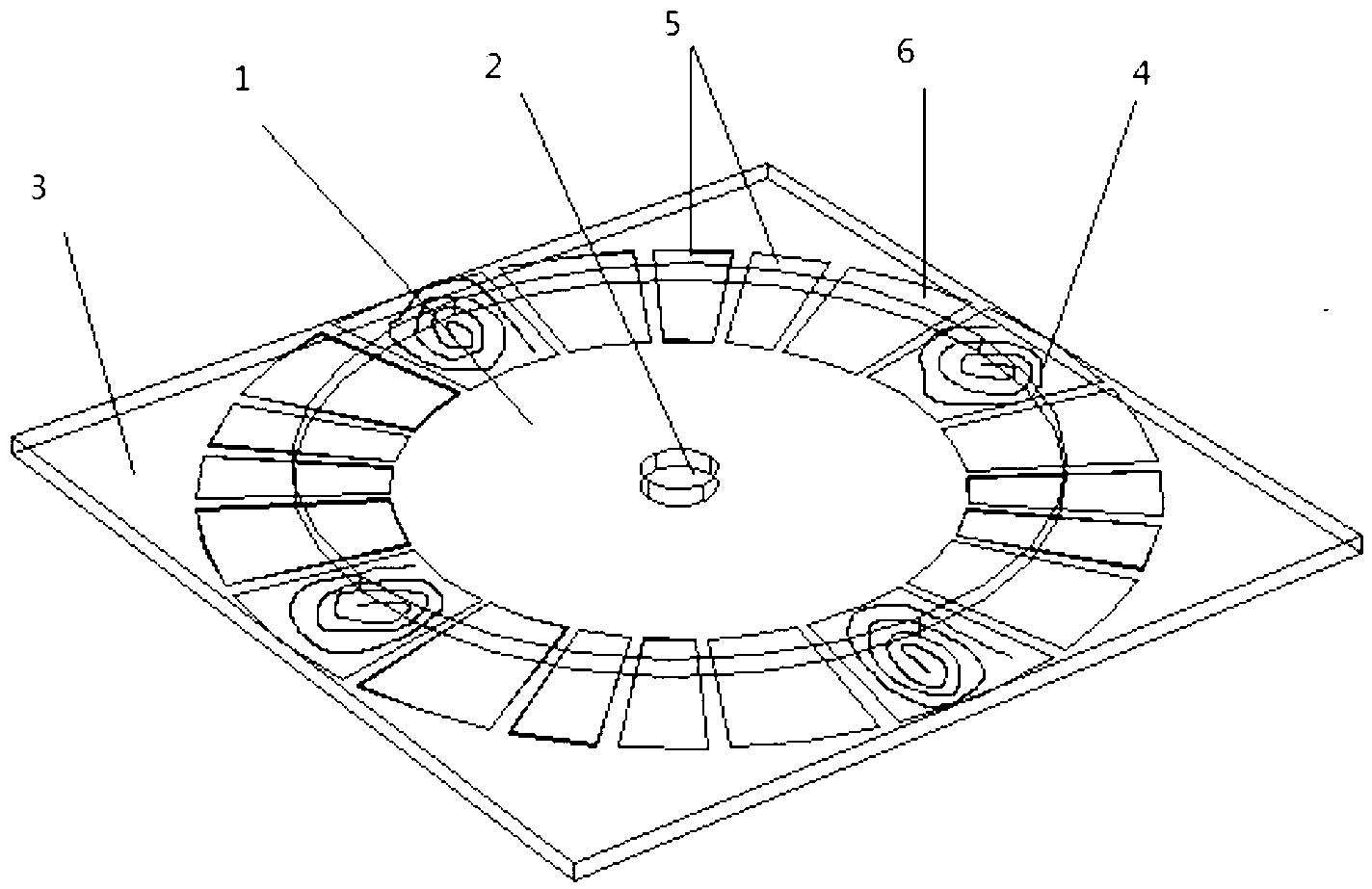

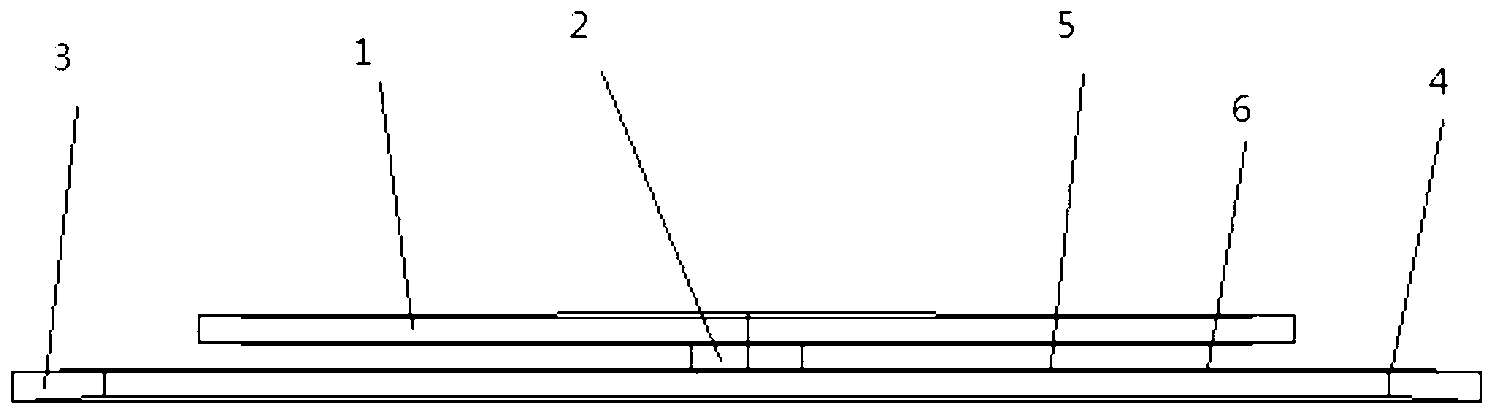

[0031] Such as figure 1 , figure 2 , image 3 As shown, this embodiment includes:

[0032] A disc vibrator 1 without a release hole;

[0033] The support column 2 located in the center below the vibrator;

[0034] Substrate 3;

[0035] The electromagnetic driving coil 4, the detection electrode 5 and the common electrode 6 are located on the substrate.

[0036] The electromagnetic drive coil 4, the detection electrode 5 and the common electrode 6 are circumferentially distributed on the substrate 3 and located below the disc vibrator 1, and are parallel to the disc vibrator 1 with a gap therebetween; The common electrode 6 is distributed between the electromagnetic driving coil 4 and the detection electrode 5 .

[0037] In this embodiment, the disc vibrator 1 is made of polysilicon, the lower surface of the vibrator is electroplated with a metal conductive layer, and is fixed on the substrate 3 through the support posts 2 . The conductive material used in the processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com