Mining drill fault intelligent identification method

An intelligent identification and drilling rig technology, applied in the field of intelligent diagnosis, can solve problems such as the inability to meet the needs of modern production of mining rigs, and achieve the effects of good real-time performance, high diagnosis accuracy and comprehensive diagnosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

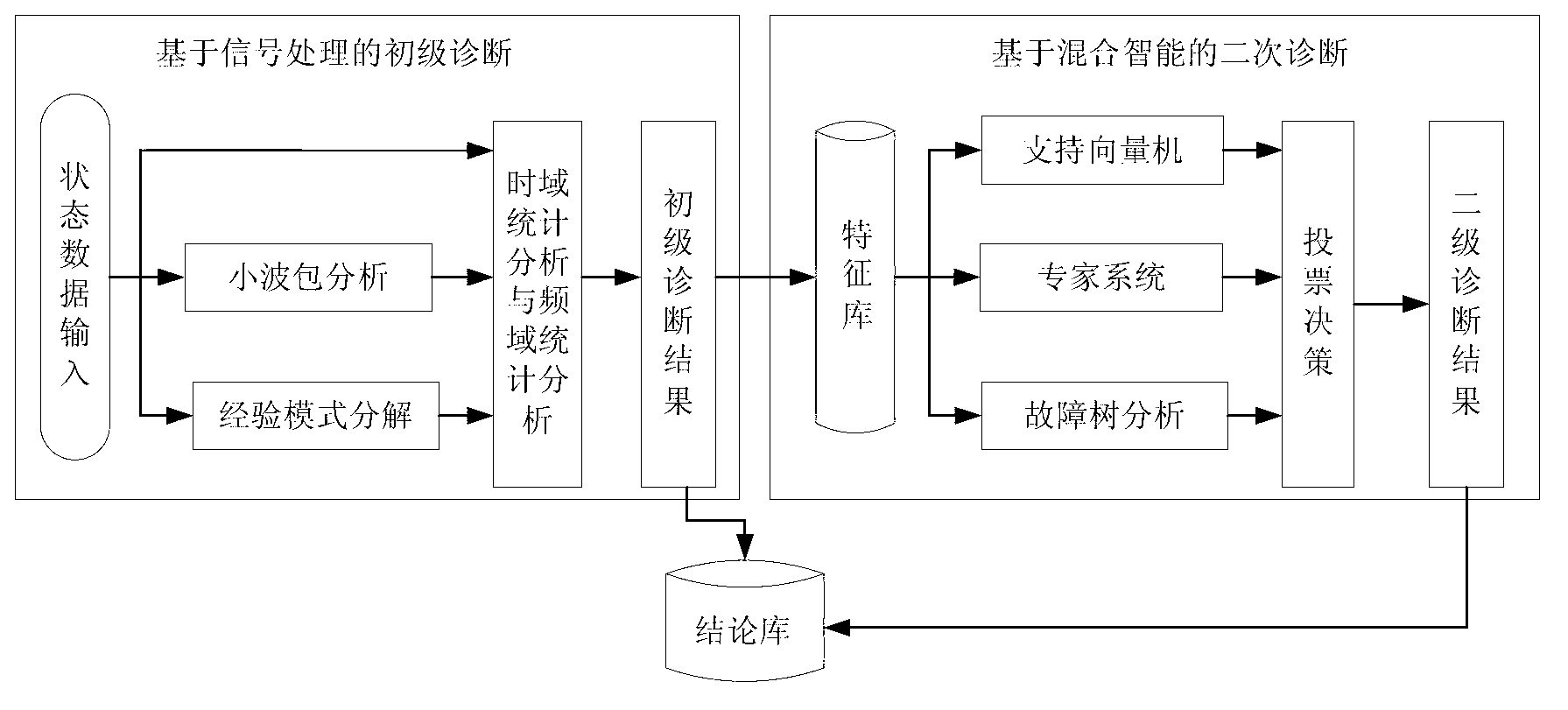

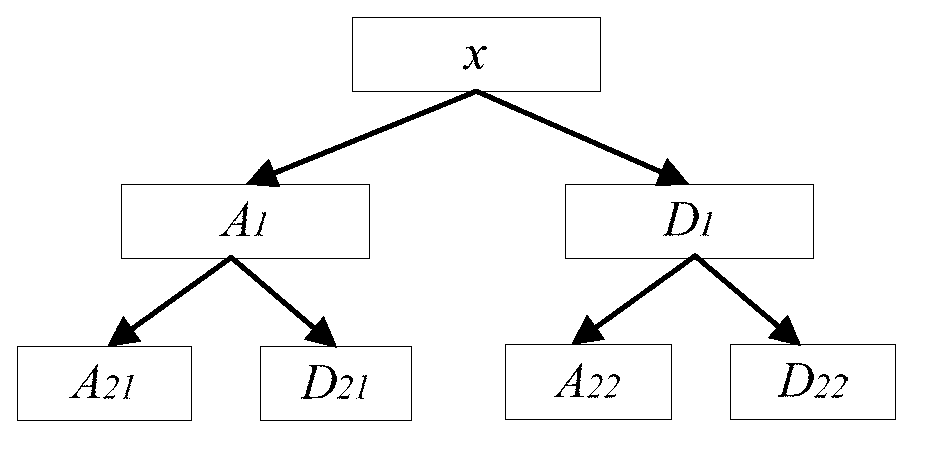

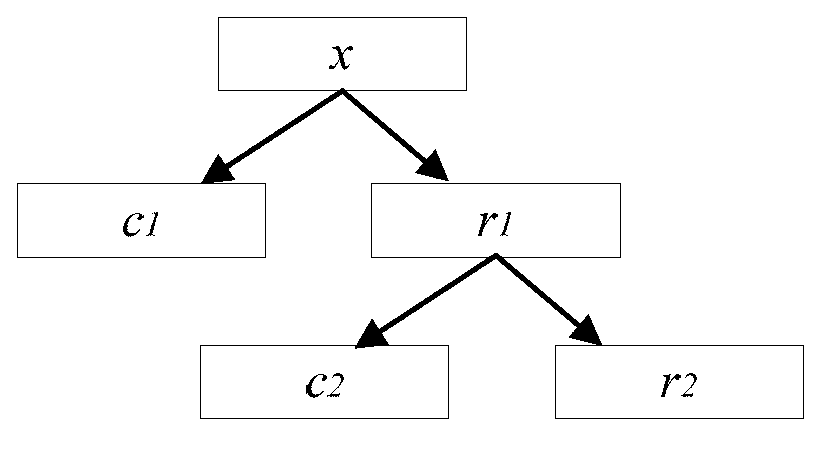

[0025] Such as figure 1 As shown in Fig. 1, an intelligent fault identification method for mining rigs mainly includes two parts: primary diagnosis based on signal processing and secondary diagnosis based on hybrid intelligence. In the primary diagnosis based on signal processing, the state data of the drilling rig is first collected as input, and then the noise signal in the state data is eliminated by wavelet packet analysis and empirical mode decomposition, the fault information is extracted, and the time-domain statistical characteristics of the original signal and the decomposed signal are calculated and frequency domain statistical characteristics, and preliminarily judge whether the drilling rig is faulty or not according to the characteristic values. In the secondary diagnosis based on hybrid intelligence, all the features of the primary diagnosis are used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com