Thread making technological parameter dynamic quality stability characterization method

A technology of quality stability and process parameters, applied in the direction of adaptive control, general control system, control/regulation system, etc., it can solve the problem of incomplete production process objects, inability to dynamically guide production quality control, and process data difficult to fully meet the positive requirements. state distribution and other problems, to achieve the effect of improving the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

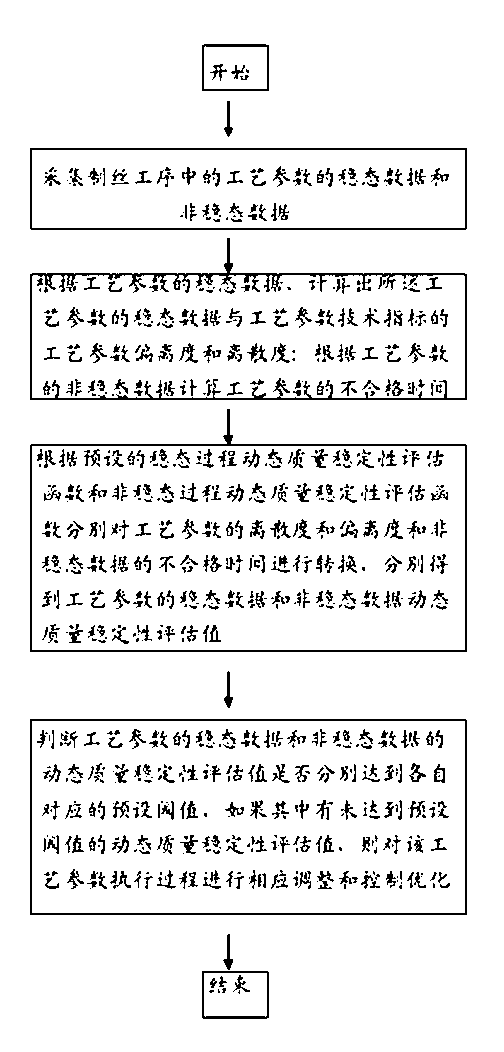

[0015] pass below figure 1 And embodiment, the technical solution of the present invention is described in further detail.

[0016] In this embodiment, the silk drying process, which is very important in the silk making process, is taken as an example, in which the process parameters can be outlet moisture content, outlet temperature, cylinder wall pressure, auxiliary air temperature, discharge hood negative pressure, electric scale flow , inlet water content and hot air temperature, etc., but not limited to the examples of process parameters mentioned above.

[0017] When collecting the steady-state data of the process parameters of the drum-type silk drying process, the collection method can also be adjusted by the technician according to the needs. When the moisture content is not lower than the preset value, the current batch of data sampling is performed on the outlet moisture content, and when the electric scale occupancy signal disappears and the outlet moisture conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com