A constant pressure control method for oil well cement curing kettle

A technology of pressure control and oil well cement, applied in the direction of electric fluid pressure control, etc., can solve the problems of strip test block maintenance, inability to test the flexural performance of oil well cement, constant pressure rise and constant pressure drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

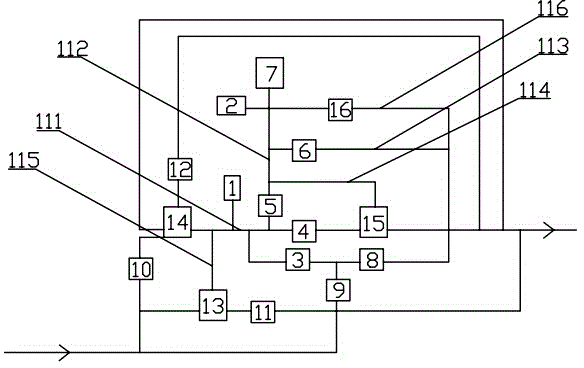

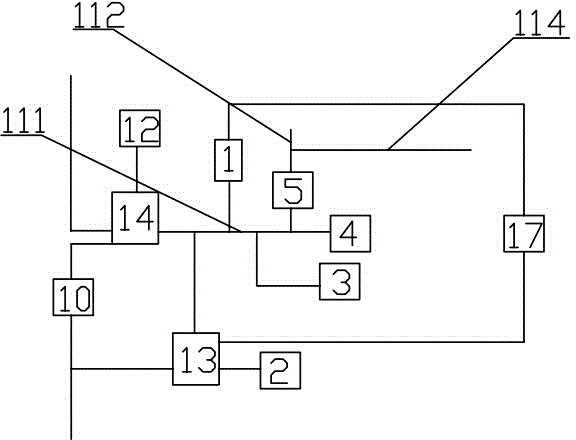

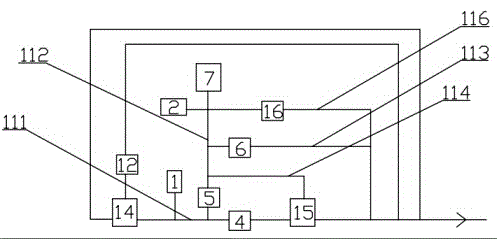

[0052] Below in conjunction with accompanying drawing, the present invention is further described:

[0053] A constant pressure control method for oil well cement curing kettle, comprising the following steps:

[0054] Constant pressure heating step: the pressure of the mold with cement samples and the kettle body of water increases after heating, and the excess pressure is released by a back pressure controller, so that the kettle body maintains a constant pressure during the heating process;

[0055] Constant pressure and constant temperature step: after the constant pressure and temperature raising step, keep the temperature constant and keep the pressure of the kettle body constant within the fluctuation range;

[0056] Constant pressure cooling step: the mold with the cement sample and the kettle body of water undergo heat exchange and cooling with cold water, and the pressure decreases. When the pressure of the kettle body is lower than the back pressure, the back pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com