Method for improving product quality in MMA production by acetone cyanohydrin method

A technology for acetone cyanohydrin and product quality, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as affecting product quality, high impurity content, and pressure fluctuations in esterification reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

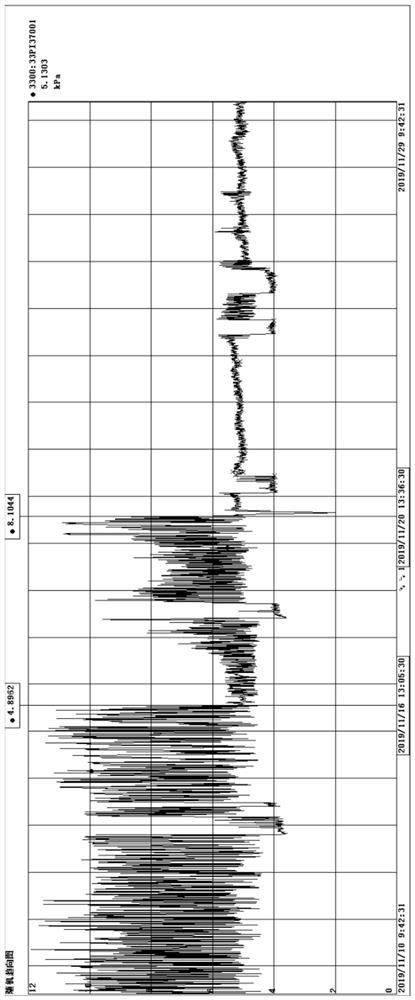

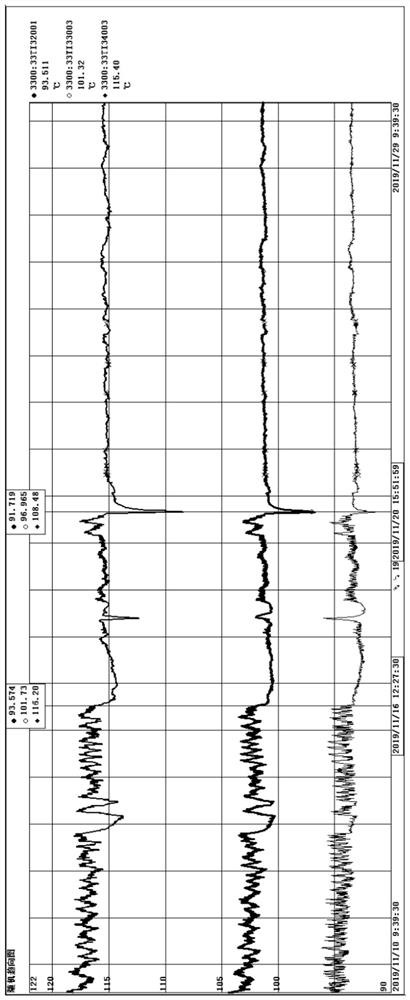

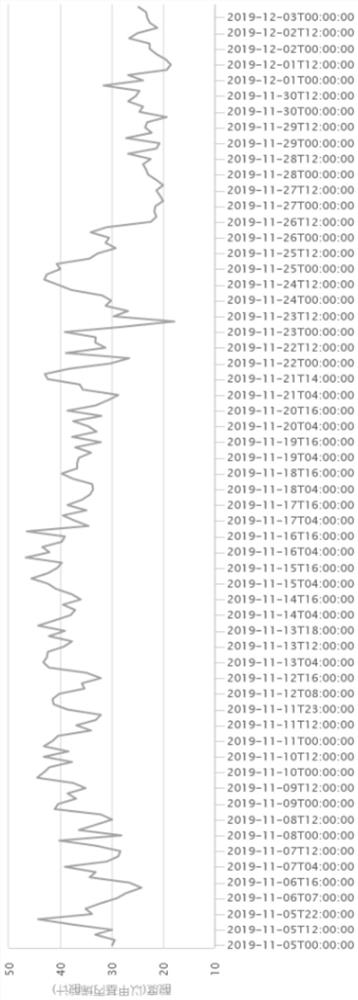

[0021] Embodiment 1, the method for improving product quality in the production of MMA by acetone cyanohydrin method,

[0022] HCN (by-product of acrylonitrile production) reacts with acetone to generate acetone cyanohydrin. The initial reaction temperature is 80°C, and then rapidly rises to 120°C. The entire reaction time is 1h. Then methanol and water esterify methacrylic acid amide sulfate, the reaction temperature is 100°C, the pressure is 7atm, and the time is 1h. Dehydration, hydrolysis and esterification generate MMA. An MMA washing tower is installed to eliminate MAA (methacrylic acid) in the esterification gas phase gas. Next to the spray water flow meter of the washing tower, a defoamer configuration tank is set, and the defoamer configuration tank is communicated with the spray water pipeline through the defoamer delivery pipeline, and the mass concentration of the washing tower delivery is 12.5%XP- 600 modified polyether defoamer aqueous solution, a metering pump...

Embodiment 2

[0023] Embodiment 2, the method for improving product quality in the production of MMA by acetone cyanohydrin method,

[0024] HCN (by-product of acrylonitrile production) reacts with acetone to generate acetone cyanohydrin. The initial reaction temperature is 100°C, and then rapidly rises to 160°C. The entire reaction time is 1h. Then methanol and water esterify methacrylic acid amide sulfate, the reaction temperature is 150°C, the pressure is 7atm, and the time is 1h. Dehydration, hydrolysis and esterification generate MMA. An MMA washing tower is installed to eliminate MAA (methacrylic acid) in the esterification gas phase gas. Next to the spray water flowmeter of the washing tower, a defoamer configuration tank is set, and the defoamer configuration tank is communicated with the spray water pipeline through the defoamer delivery pipeline, and the mass concentration of the washing tower delivery is 25%XP- 600 modified polyether defoamer aqueous solution, a metering pump i...

Embodiment 3

[0025] Embodiment 3, the method for improving product quality in the production of MMA by acetone cyanohydrin method,

[0026] HCN (by-product of acrylonitrile production) reacts with acetone to generate acetone cyanohydrin. The initial reaction temperature is 90°C, and then rapidly rises to 140°C. The entire reaction time is 1h. Then methanol and water esterify methacrylic acid amide sulfate, the reaction temperature is 1300°C, the pressure is 7atm, and the time is 1h. Dehydration, hydrolysis and esterification generate MMA. An MMA washing tower is installed to eliminate MAA (methacrylic acid) in the esterification gas phase gas. Next to the spray water flow meter of the washing tower, a defoamer configuration tank is arranged, and the defoamer configuration tank is communicated with the spray water pipeline through the defoamer delivery pipeline, and the mass concentration of the washing tower delivery is 18%XP- 600 modified polyether defoamer aqueous solution, a metering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com