Heat dissipating system and blade server

A blade server and heat dissipation system technology, which is applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve the problem of less research on memory liquid cooling technology, different memory quantity and spacing, and difficult unified design of liquid cooling products and other issues, to achieve the effect of improving cooling efficiency and speed, uniform distribution and recovery, and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

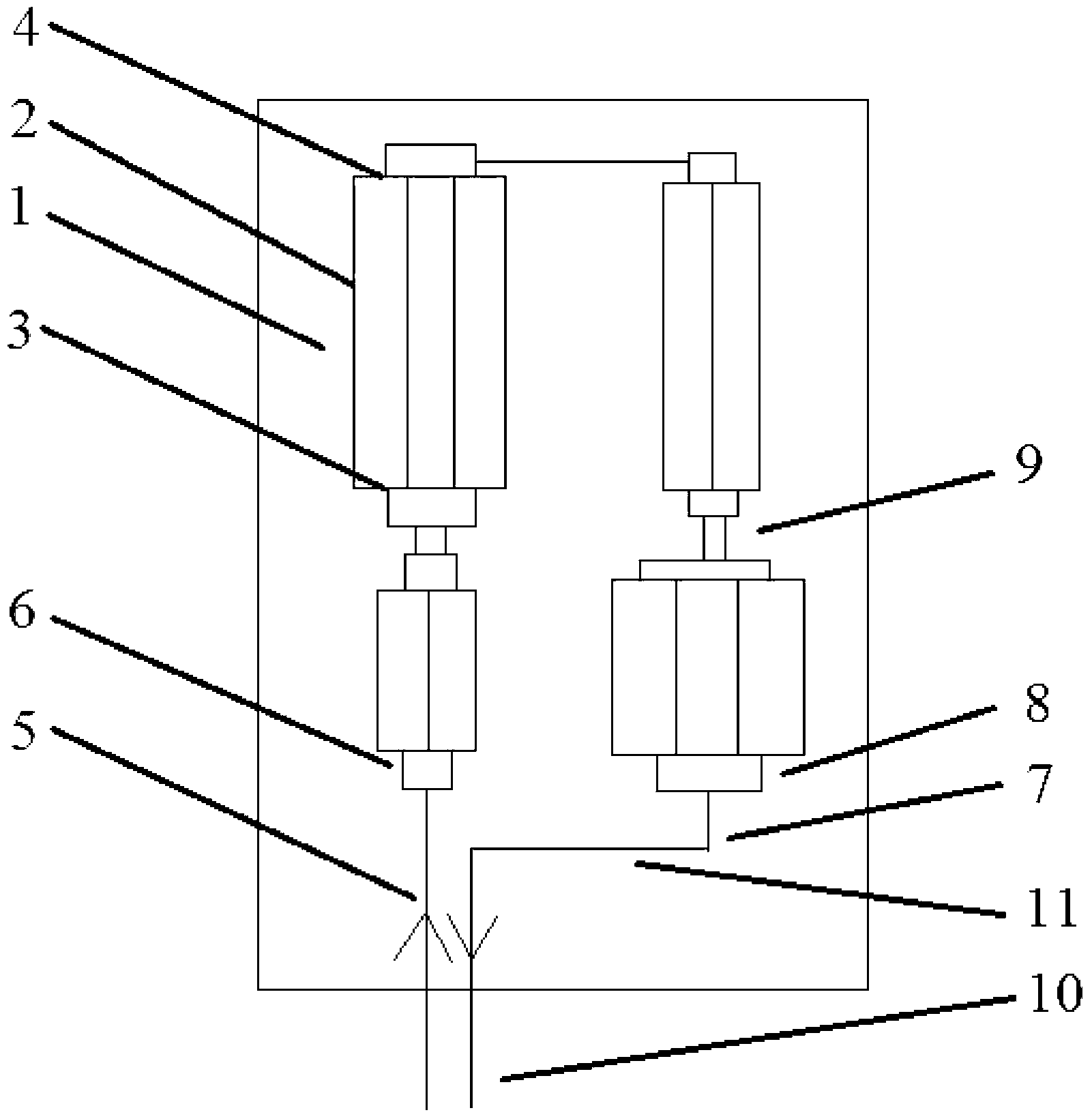

[0021] Now refer to figure 1 The heat dissipation system of the present invention is described, which includes at least two liquid cooling block groups 1 , a liquid inlet pipe 5 and a first liquid distribution block 6 , a liquid outlet pipe 7 and a second liquid distribution block 8 , and an intermediate liquid distribution block 9 . Wherein, each liquid cooling block group 1 has at least two liquid cooling blocks 2, and each liquid cooling block 2 includes a refrigerant inlet 3 and a refrigerant outlet 4, and one end of the first liquid sub-block 6 communicates with the liquid inlet pipe 5, and the other One end communicates with the refrigerant inlet 3 of each liquid cooling block 2 in the liquid cooling block group 1 respectively. Further, one end of the second liquid separation block 8 communicates with the liquid outlet pipe 7 , and the other end communicates with the refrigerant outlets 4 of the liquid cooling blocks 2 in the liquid cooling block group 1 respectively. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com