Non-encapsulated dry type power transformer

A power transformer, dry-type technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of poor insulation performance, shortened service life of transformer, high noise, etc., and achieve the best electrical performance and mechanical performance, environmental protection effect Good, good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

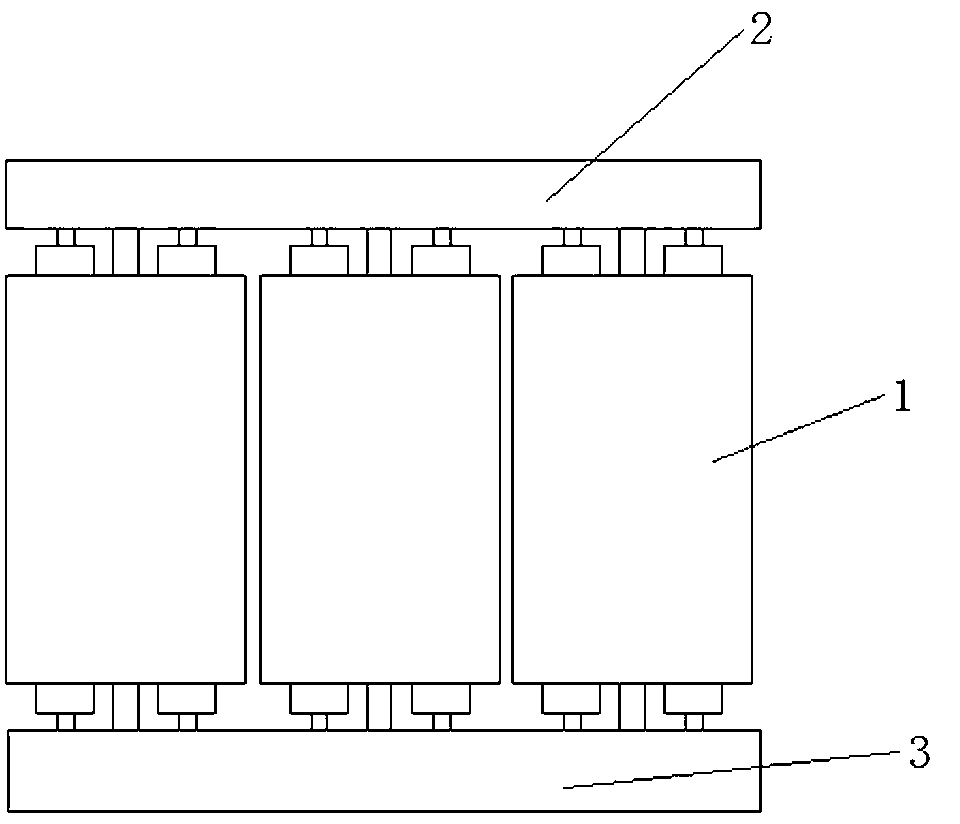

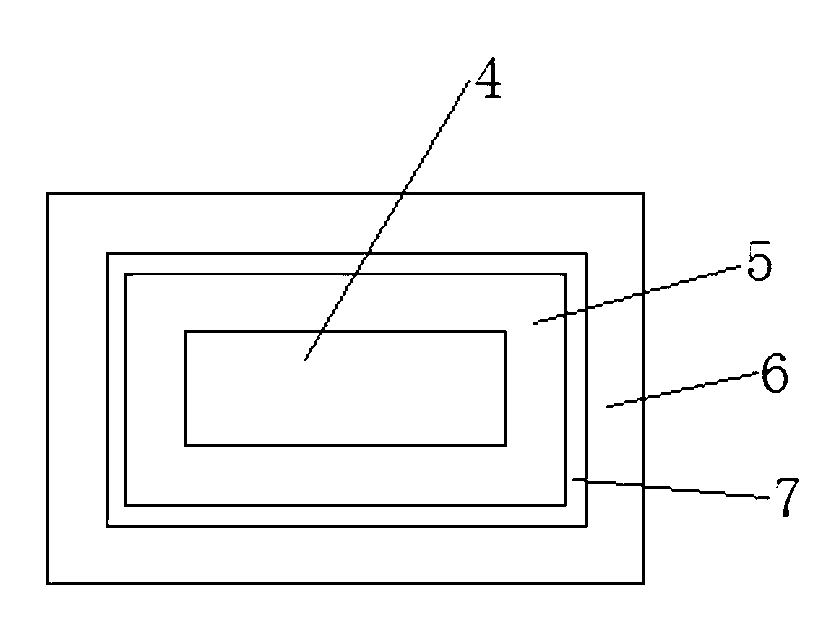

[0009] Such as figure 1 , figure 2 As shown, the non-encapsulated dry-type power transformer includes a winding assembly 1, an upper fixing member 2 arranged at the top end of the winding assembly 1, and a lower fixing member 3 arranged at the bottom end of the winding assembly 1, and the winding assembly 1 includes Iron core 4, low-voltage winding 5 and high-voltage winding 6 wound on the iron core 4, Nomex insulating paper 7 is arranged between the low-voltage winding 5 and high-voltage winding 6, and the low-voltage winding 5 and high-voltage winding 6 are both Vacuum pressure impregnation with class H solvent-free insulating varnish. In this embodiment, because the high-voltage and low-voltage windings are all subjected to vacuum pressure impregnation with H-class solvent-free insulating varnish and high-temperature solid treatment, they maintain extre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com