Method for controlling cusped magnetic field thruster plume divergent angle

A cusp magnetic field and thruster technology, which is applied in the field of controlling the plume divergence angle by the configuration of the magnetic interface of the cusp magnetic field thruster, can solve the problems such as the difficulty in controlling the plume divergence angle of the cusp magnetic field thruster, and achieve reduction Effect of Small Plume Divergence Angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

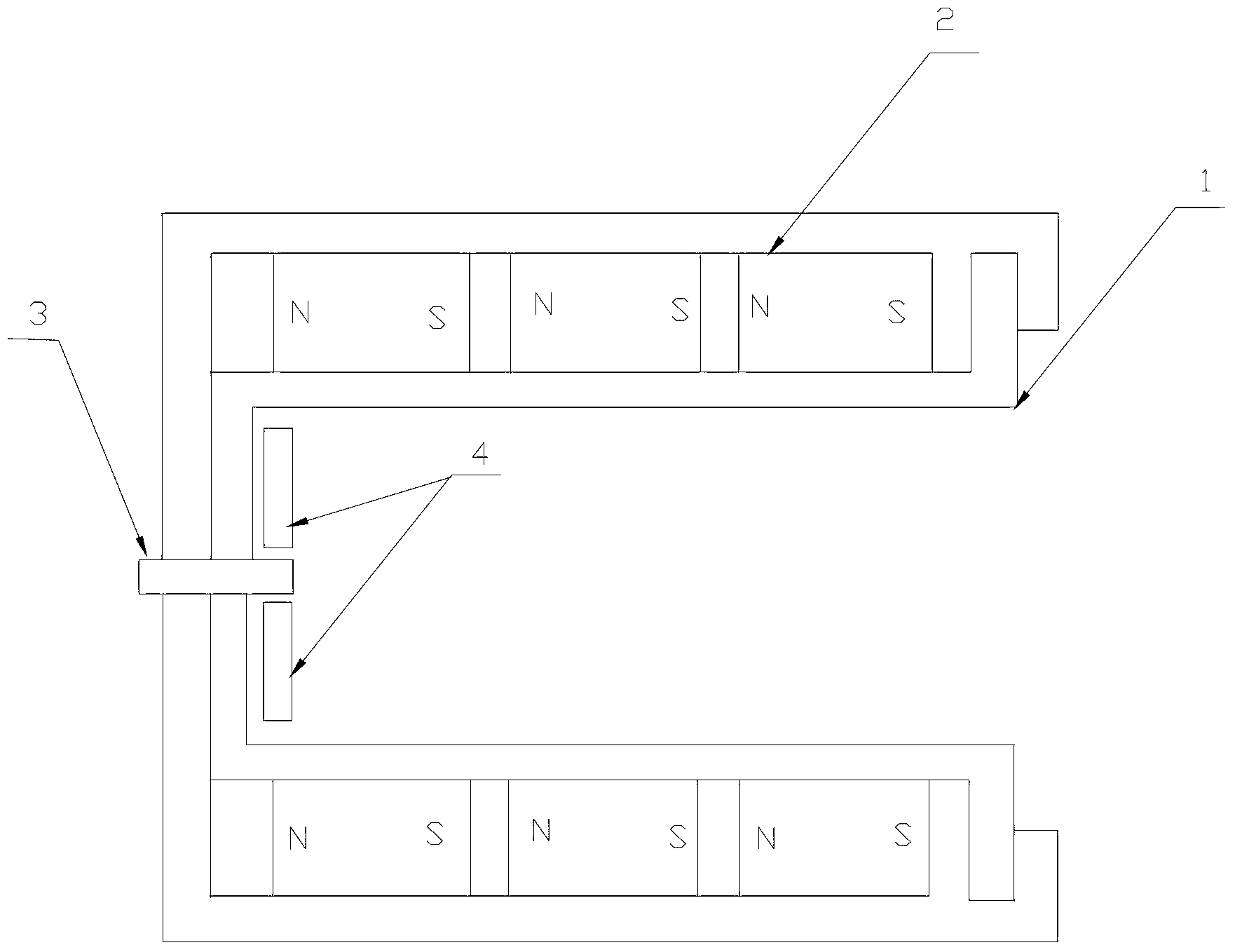

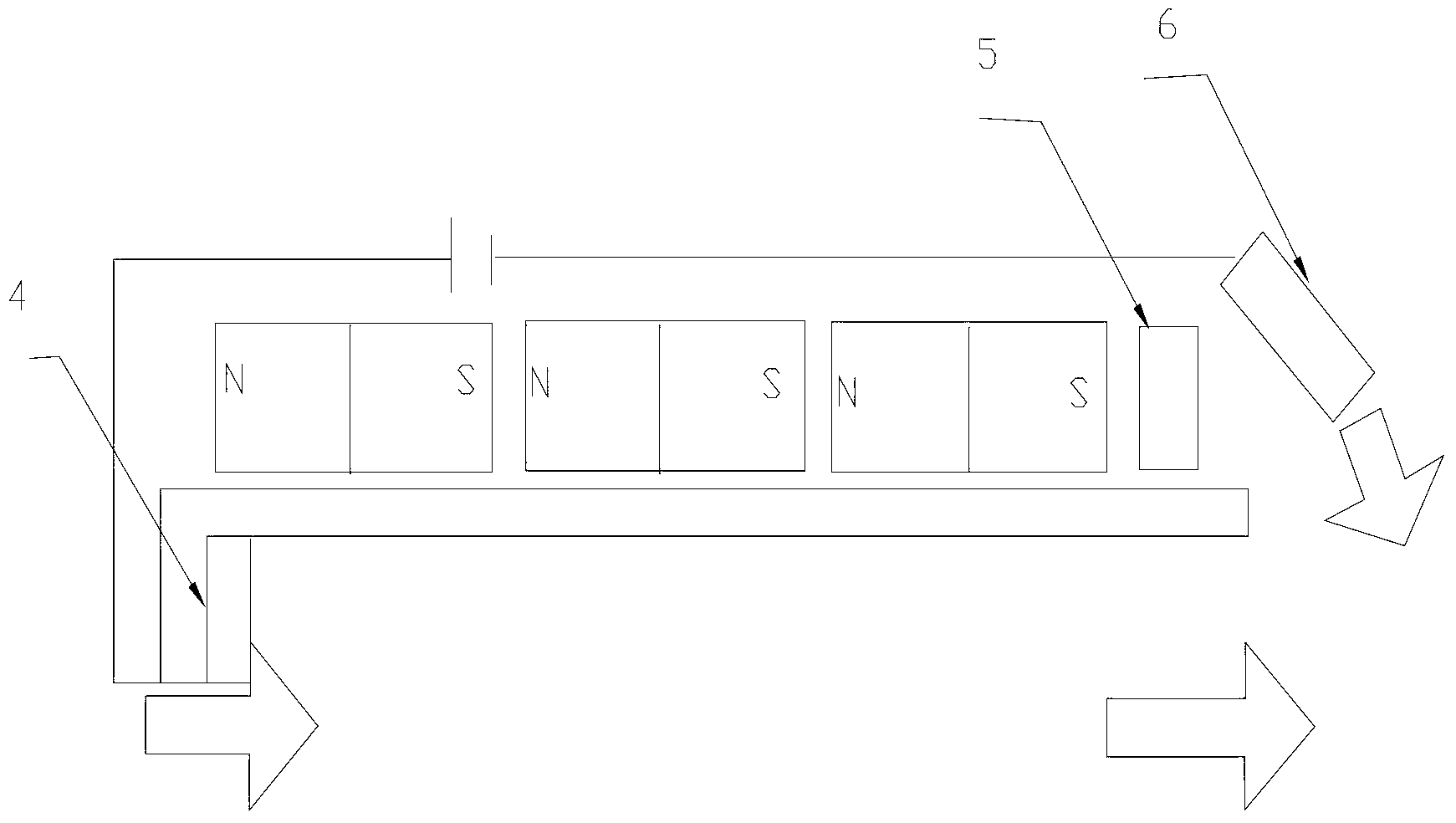

[0014] Specific implementation mode 1. Combination figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment, a method for controlling the plume divergence angle of a tangential magnetic field thruster described in this embodiment, the specific steps of the method are:

[0015] Step 1. Fix an annular plume control permanent magnet on the outside of the outermost permanent magnet at the outlet of the discharge channel of the tangential magnetic field thruster; The polarity of the permanent magnet is opposite;

[0016] Step 2: Ignite the cathode of the cusp magnetic field thruster, the cathode of the thruster emits electrons, and the electrons move to the inside of the discharge channel under the action of the electromagnetic field;

[0017] Step 3. Introduce xenon gas into the discharge channel of the cusp magnetic field thruster, and gradually increase the anode voltage with a step size n until the thruster ignites successfully; where n is a positive integer, ...

specific Embodiment approach 2

[0025] Specific Embodiment 2. This embodiment is a further description of a method for controlling the plume divergence angle of a tangential magnetic field thruster described in Embodiment 1. The annular plume control permanent magnet described in step 1 consists of a shaft It is composed of a permanent magnet magnetized radially and a permanent magnet magnetized radially.

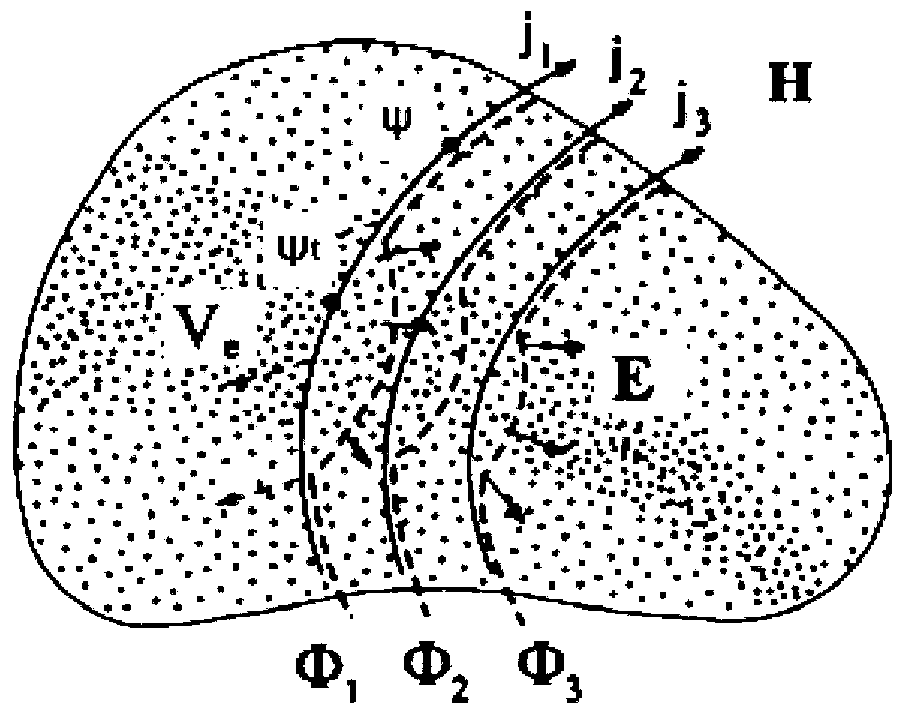

[0026] An annular axial permanent magnet is placed above the permanent magnet of the tangential magnetic field thruster, and its polarity is opposite to that of the permanent magnet of the tangential magnetic field thruster. The degree of convexity of the magnetic interface after the axial permanent magnet is installed is the same as that without installation Compared with the axial permanent magnet, the outer convex degree of the magnetic interface is significantly lower, so the installation of the permanent magnet ring with opposite polarity can effectively improve the configuration of the magnetic inter...

specific Embodiment approach 3

[0030] Specific Embodiment Three. This embodiment is a further description of a method for controlling the plume divergence angle of a tangential magnetic field thruster described in Embodiment Two. The axial length of the radially magnetized permanent magnet is less than or equal to 5mm .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com