Apparatus and method for treating organic waste

A technology for organic waste and reaction vessels, which is applied in the preparation of organic fertilizers, chemical instruments and methods, mixers with rotating stirring devices, etc., and can solve problems such as long processing periods, complicated processing processes, and large processing sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

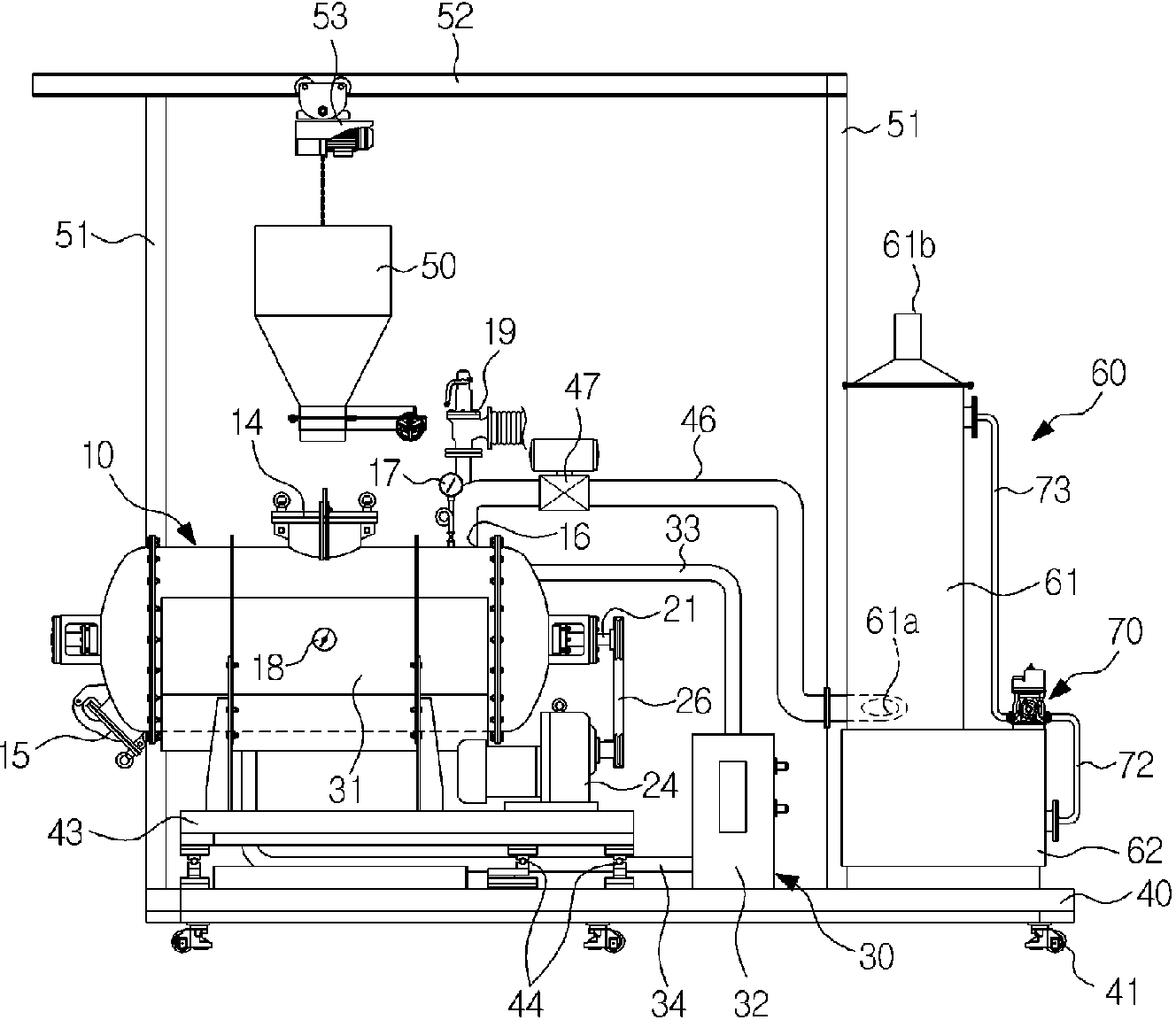

[0030] like figure 1 and 2 The shown device for treating organic waste of the present invention includes a reaction vessel 10, an agitator 20 for stirring the material in the reaction vessel 10, a preheater 30 for preheating the reaction vessel 10 and a condensing reaction gas And generate the liquid fertilizer generator 60 of liquid fertilizer. Further, the device can further include a base 40 installed on a plurality of movable casters 41 and used to install and support the reaction vessel 10, the liquid fertilizer generator 60 and the preheater 30, and a base 40 installed on the base 40. The container frame 43 for supporting the reaction container 10 and the movable hopper 50 for conveniently supplying materials to the reaction container 10 .

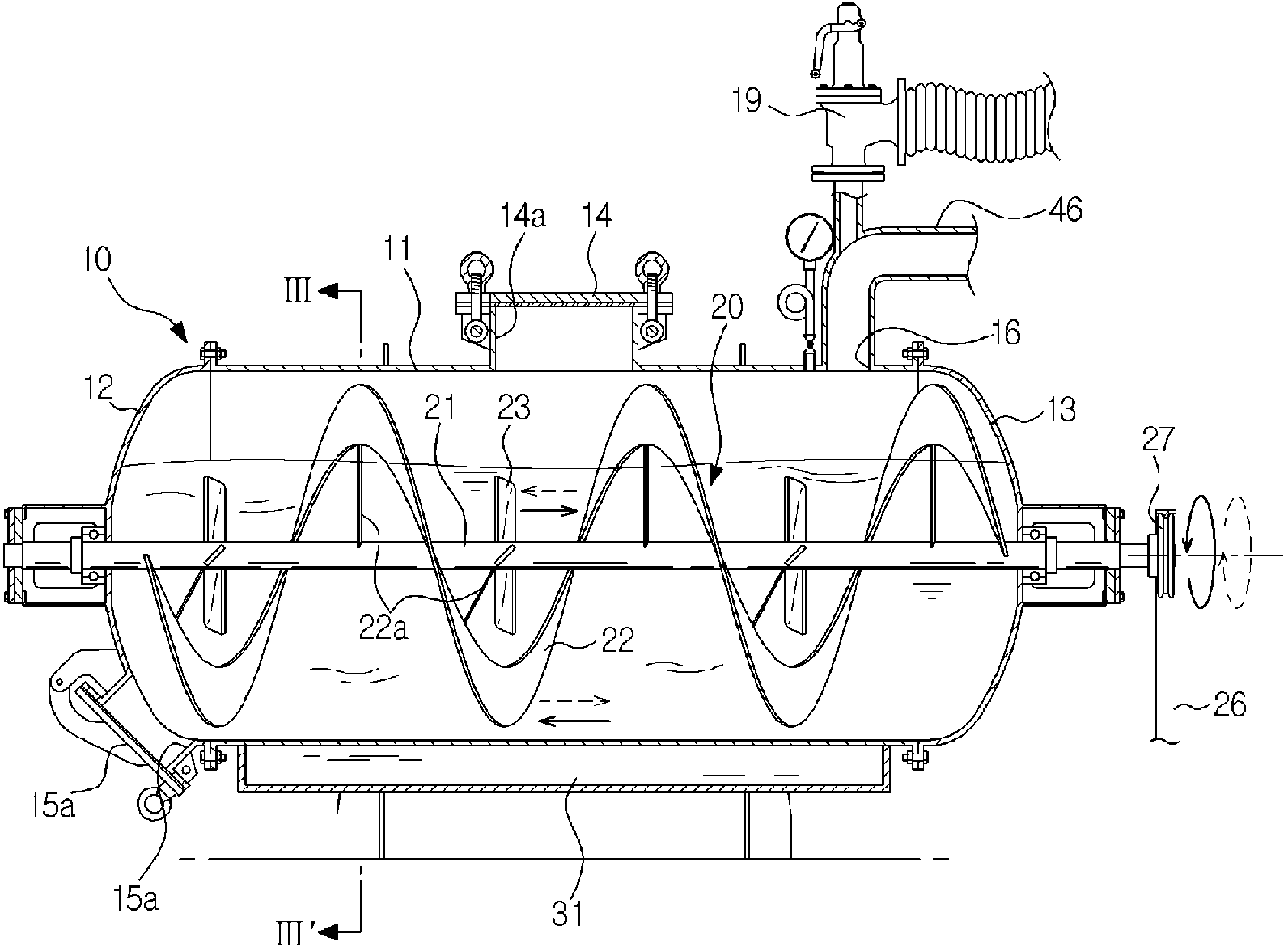

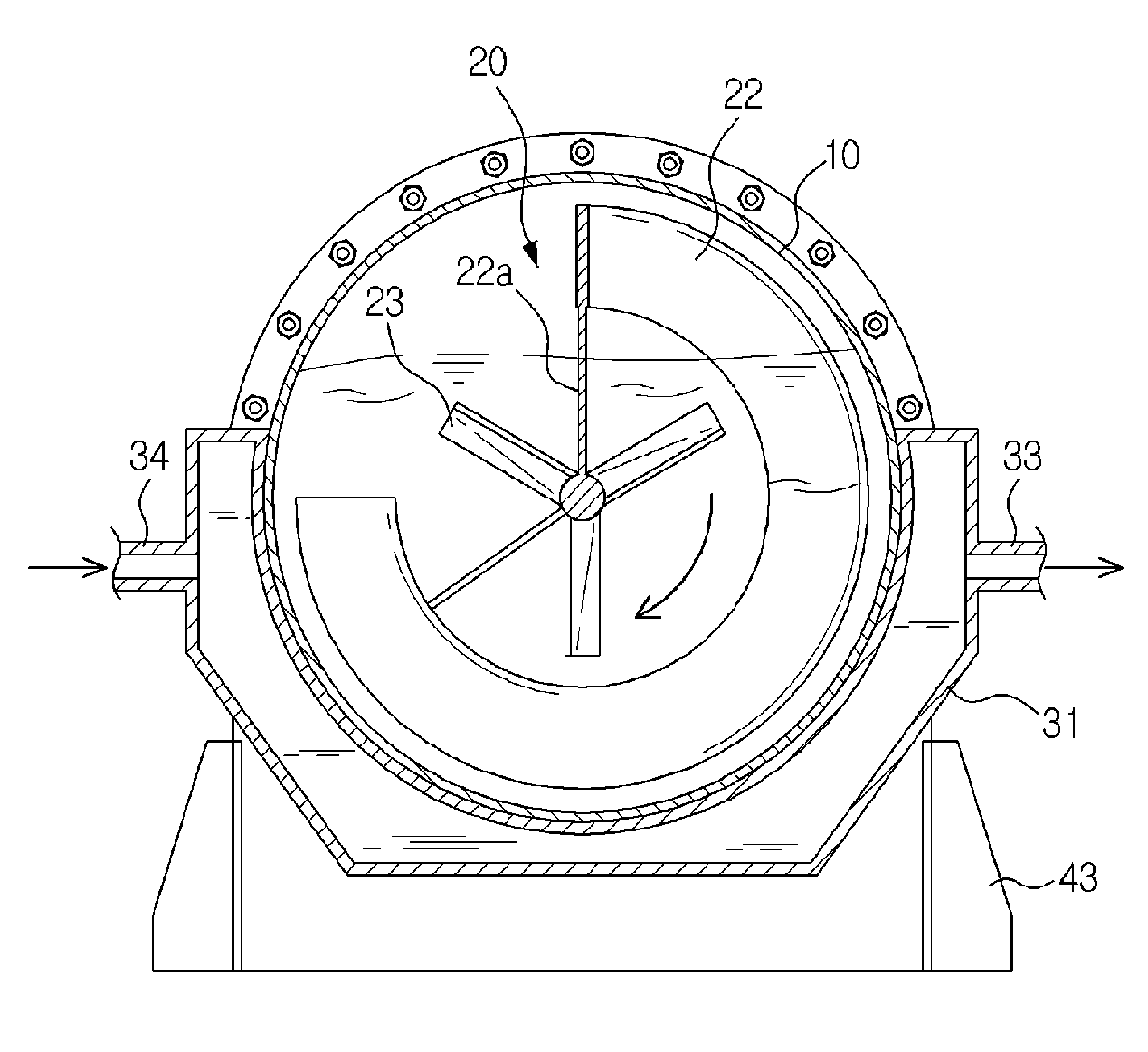

[0031] attached figure 2 The shown reaction vessel 10 includes a cylinder 11 with two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com