Power transmission device for vehicle

A technology for transmitting device and driving force, applied in the direction of fluid drive clutch, non-mechanical drive clutch, clutch, etc., can solve the problem of limited application parts, and achieve the effect of improving reliability, realizing axial size, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

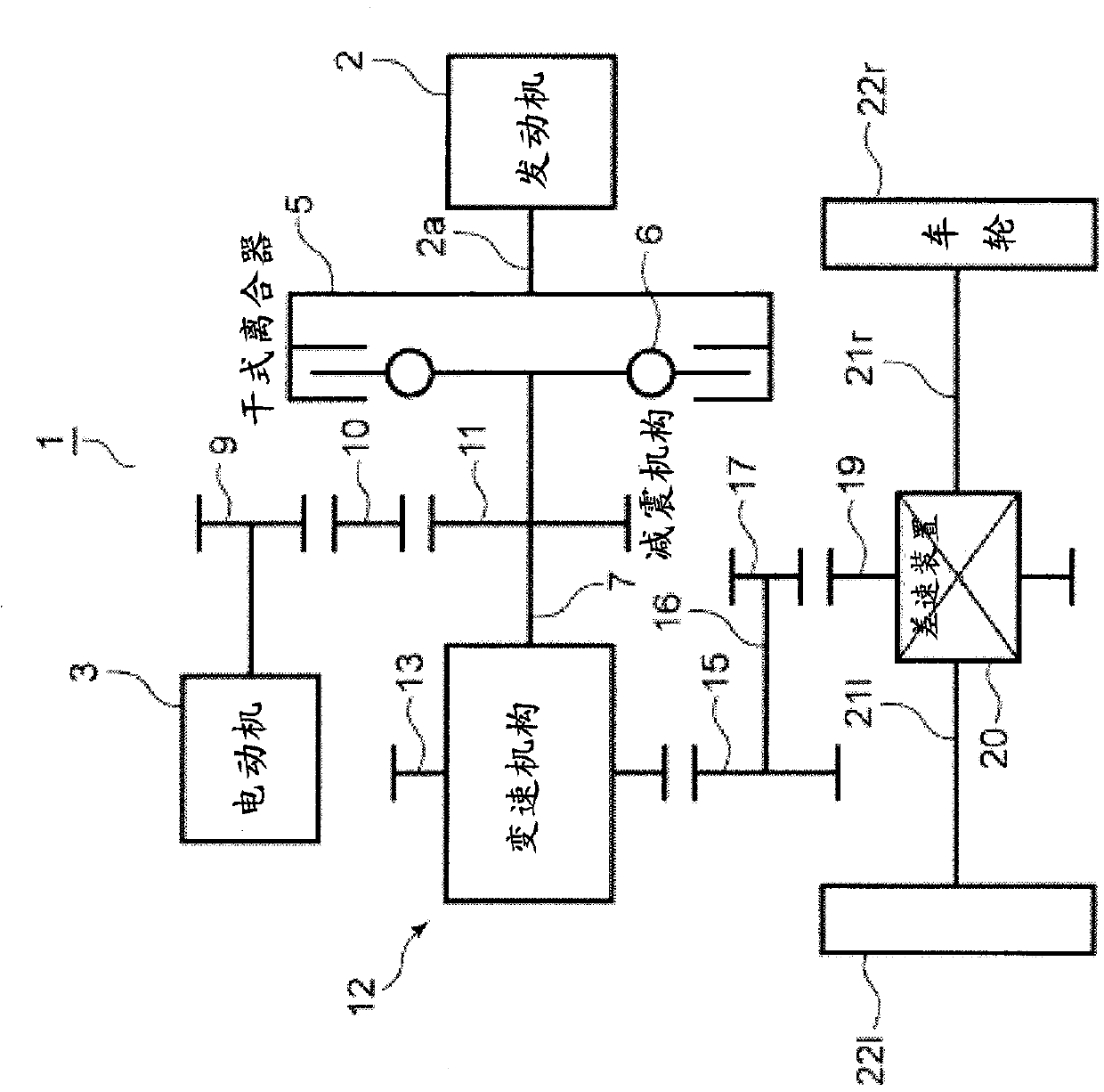

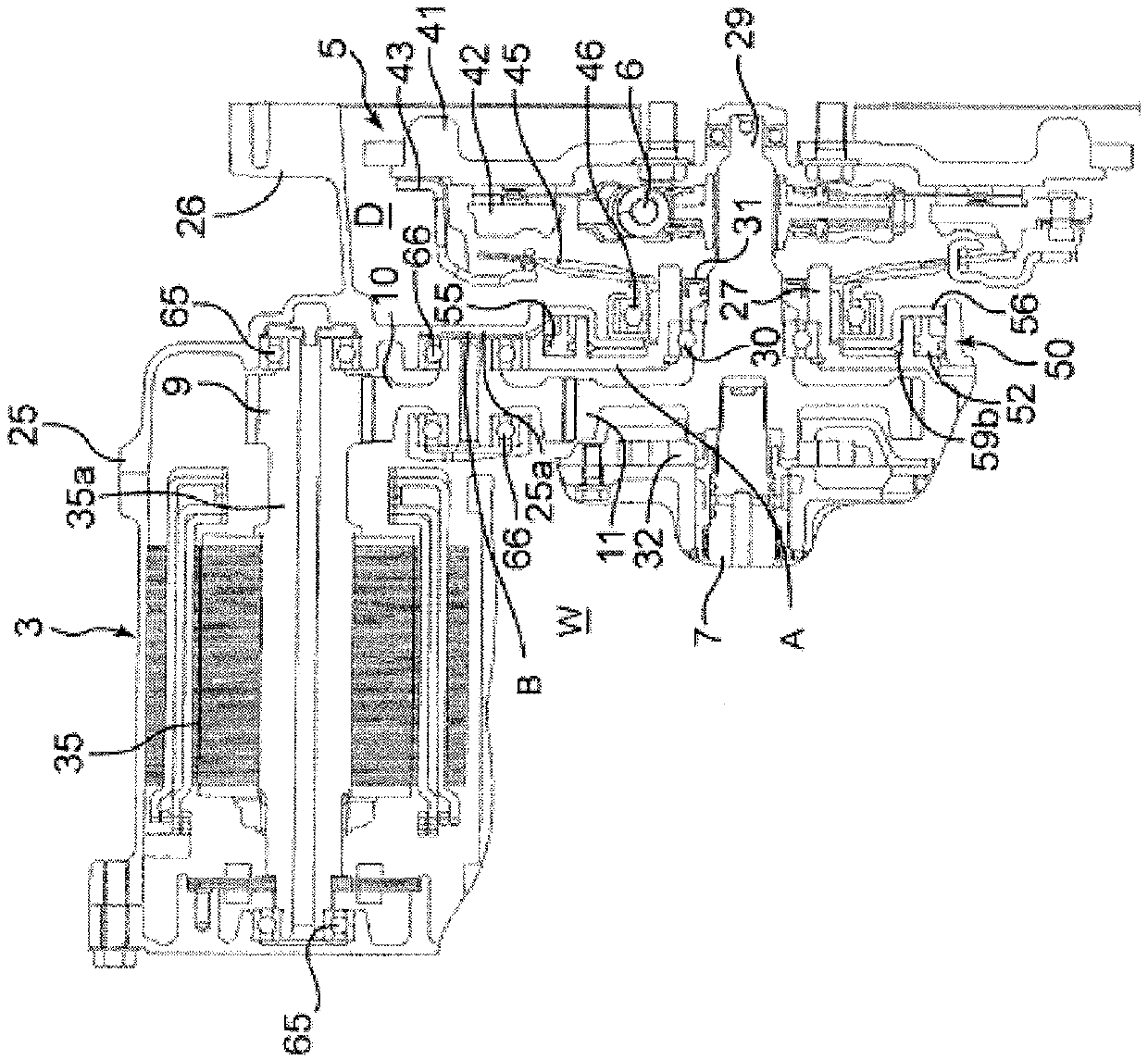

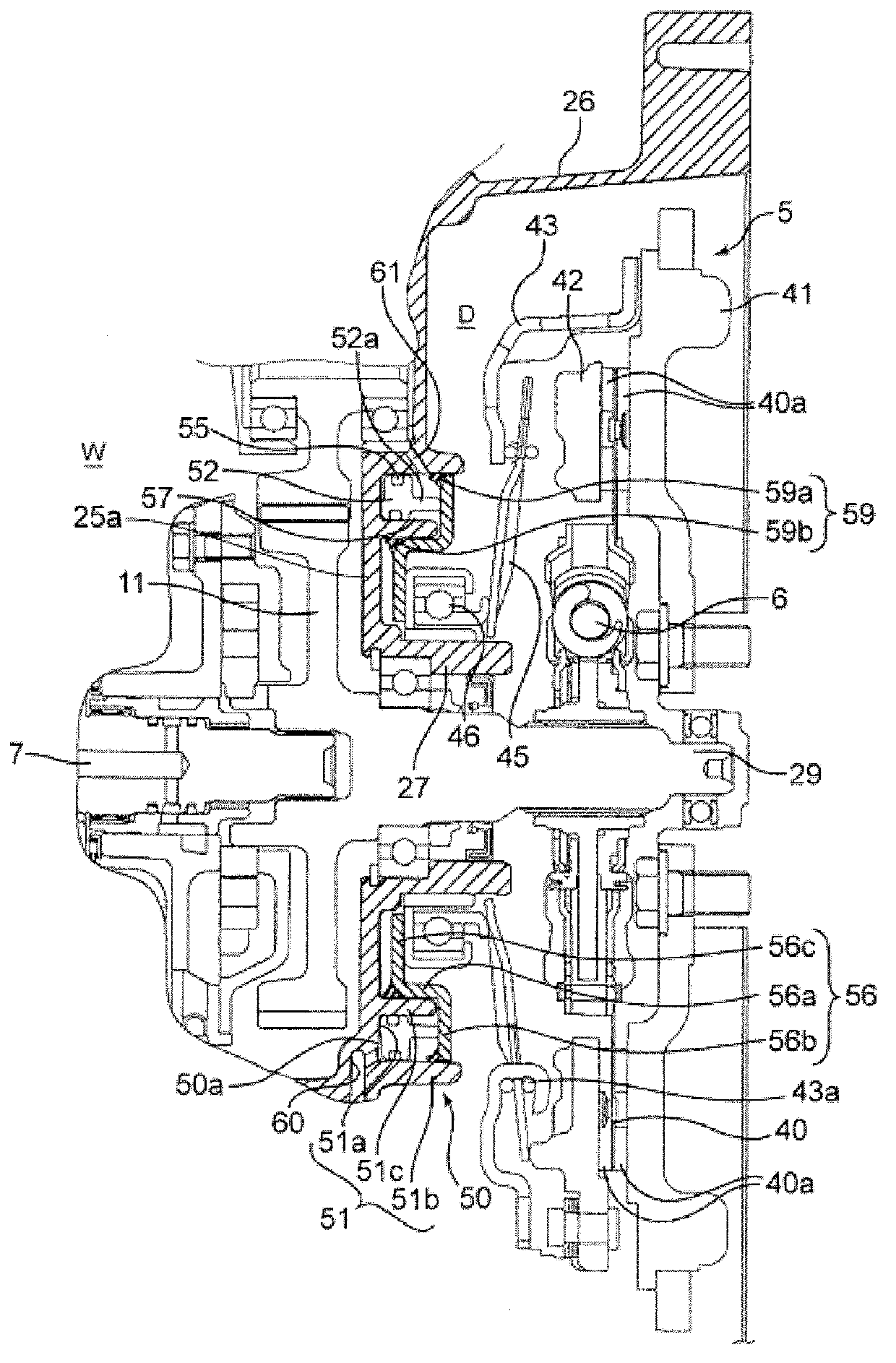

[0032] Next, the driving force transmission device for a vehicle of the present invention will be described based on the drawings. The driving force transmission device for the vehicle is applied as a single-motor type hybrid driving device 1, such as figure 1 As shown, the internal combustion engine 2 and the electric motor 3 are provided as the driving source. The output shaft 2a of the engine 2 is connected to the input shaft 7 via a dry clutch 5 and a damper spring 6. The rotor of the electric motor 3 is connected to the gear 11 provided on the input shaft 7 via the output gear 9 and the idler gear 10.

[0033] The rotation of the input shaft 7 is transmitted to the counter transmission gear 13 after being shifted by the transmission mechanism 12, and is also transmitted to the counter shaft 16 via the counter driven gear 15. The rotation of the countershaft 16 is transmitted to the differential device 20 via the gear 17 and the differential mount gear 19, and then is transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com