Production method of oolong black tea

A production method and technology of oolong red, applied in the direction of pre-extraction tea treatment, etc., can solve the problems of difficulty in forming finished tea, difficult to balance processing of terminal buds and fourth leaves, high weather dependence, etc., so as to increase yield and reduce dependence. performance, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

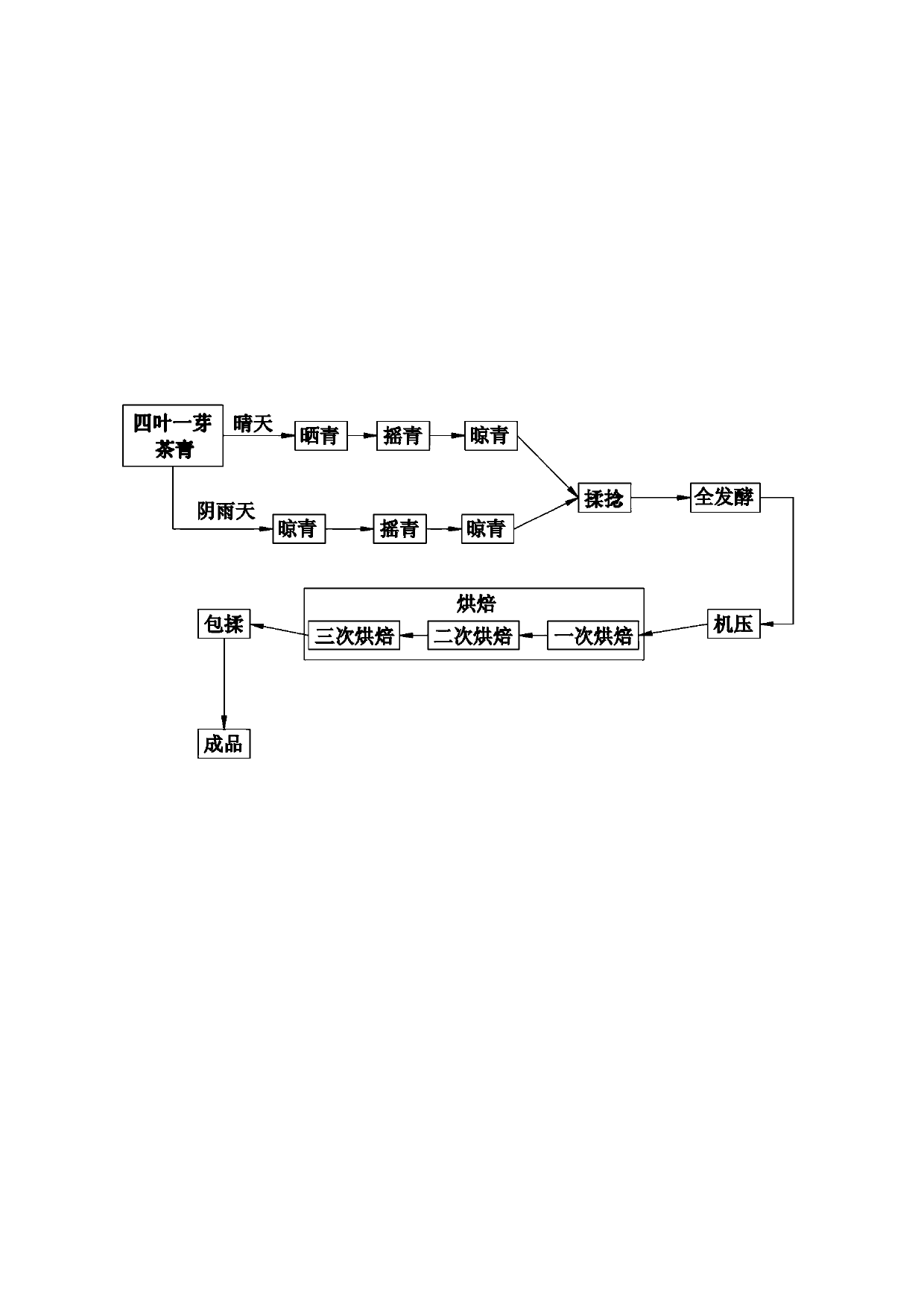

[0020] refer to figure 1 A method for producing oolong red in sunny days. The preparation of the oolong red in sunny days includes the following steps: picking the dark green of oolong tea with four leaves and one bud → drying green → shaking green → drying green → kneading → full fermentation → machine pressing → Kneading (2 to 3 times) → Baking → Finished product. The shape of the oolong red prepared according to the process is spherical. If it is necessary to prepare the bar-shaped oolong red, the green tea in the production method can be directly baked after being fully fermented.

[0021] Drying the blue is to pre-spread the tea towels or tea towels on the green drying field, and then spread the tea greens on the tea towels or tea towels, and control the thickness of the spreading leaves between 2-3cm, and dry the greens in the sun for 30- 40 minutes; the drying time is 8-11 in the morning or 3-5 in the afternoon on a sunny day, and the tea is turned at least once during...

Embodiment approach 2

[0028] refer to figure 1 A method for producing oolong red in sunny days. The preparation of the oolong red in sunny days includes the following steps: picking the dark green of oolong tea with four leaves and one bud → drying green → shaking green → drying green → kneading → full fermentation → machine pressing → Kneading (2 to 3 times) → Baking → Finished product.

[0029] Drying the blue is to pre-spread the tea towels or tea towels on the green drying field, and then spread the tea greens on the tea towels or tea towels, and control the thickness of the spreading leaves between 2-3cm, and dry the greens in the sun for 30- 40 minutes; the drying time is 8-11 in the morning or 3-5 in the afternoon on a sunny day, and the tea is turned at least once during the drying process.

[0030] The time of shaking blue and green is 20 minutes.

[0031] The above kneading steps include: put the fresh leaves after full fermentation into the kneading machine, the pressure follows light-...

Embodiment approach 3

[0036] refer to figure 1 A method for producing oolong red in sunny days. The preparation of the oolong red in sunny days includes the following steps: picking the dark green of oolong tea with four leaves and one bud → drying green → shaking green → drying green → kneading → full fermentation → machine pressing → Kneading (2 to 3 times) → Baking → Finished product.

[0037] Drying the blue is to pre-spread the tea towels or tea towels on the green drying field, and then spread the tea greens on the tea towels or tea towels, and control the thickness of the spreading leaves between 2-3cm, and dry the greens in the sun for 30- 40 minutes; the drying time is 8-11 in the morning or 3-5 in the afternoon on a sunny day, and the tea is turned at least once during the drying process.

[0038] The time of shaking blue and green is 10 minutes.

[0039] The above kneading steps include: put the fresh leaves after full fermentation into the kneading machine, the pressure follows light-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com