Automatic fodder production system

A technology for automatic production and feed, applied in the fields of feed, food science, application, etc., can solve the problems of easy dust clogging of the pipe wall, difficult pipeline transportation, poor working environment, etc., to achieve a high degree of automation, improve the environment, and ensure product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

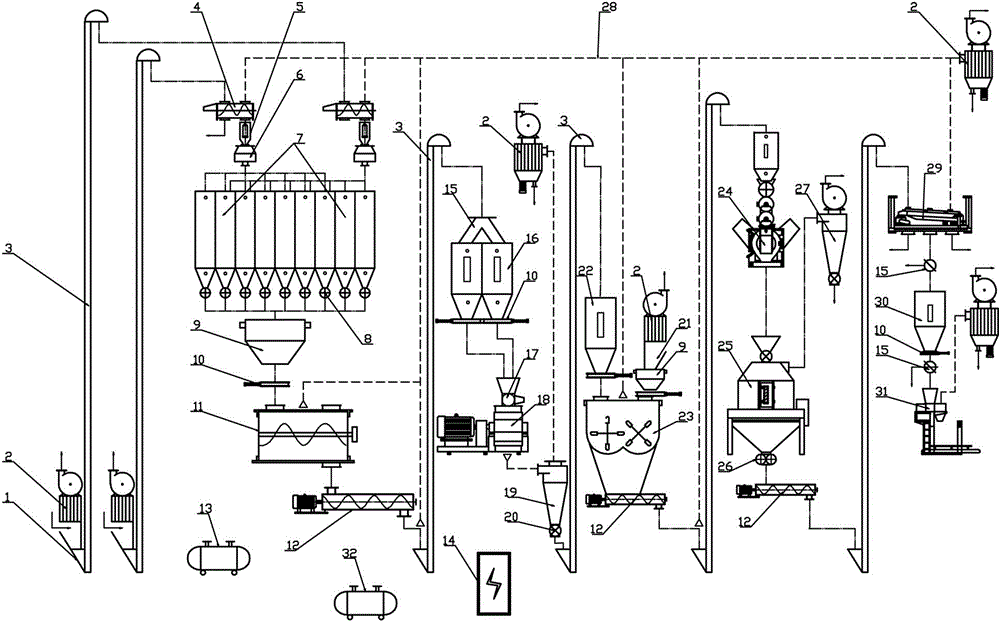

[0033] Such as figure 1 Among them, an automatic feed production system, comprising:

[0034] Before the batching bin 7, at least two elevators 3 are arranged, and the elevators are respectively connected with the first sieve machine 4, and the first sieve machine 4 is provided with a magnetic slag removal device 5 for removing iron slag in the material and for feeding each ingredient. The rotary distributor 6 supplied by the bin 7, and each first sieving machine 4 is respectively connected with a part of the batching bin 7. A material level device is provided in the batching bin 7, and the stocking situation of the batching bin is controlled through the material level device in the batching bin. With this structure, the storage capacity of each batching bin 7 can be adjusted conveniently. It is convenient to change the ratio of feed.

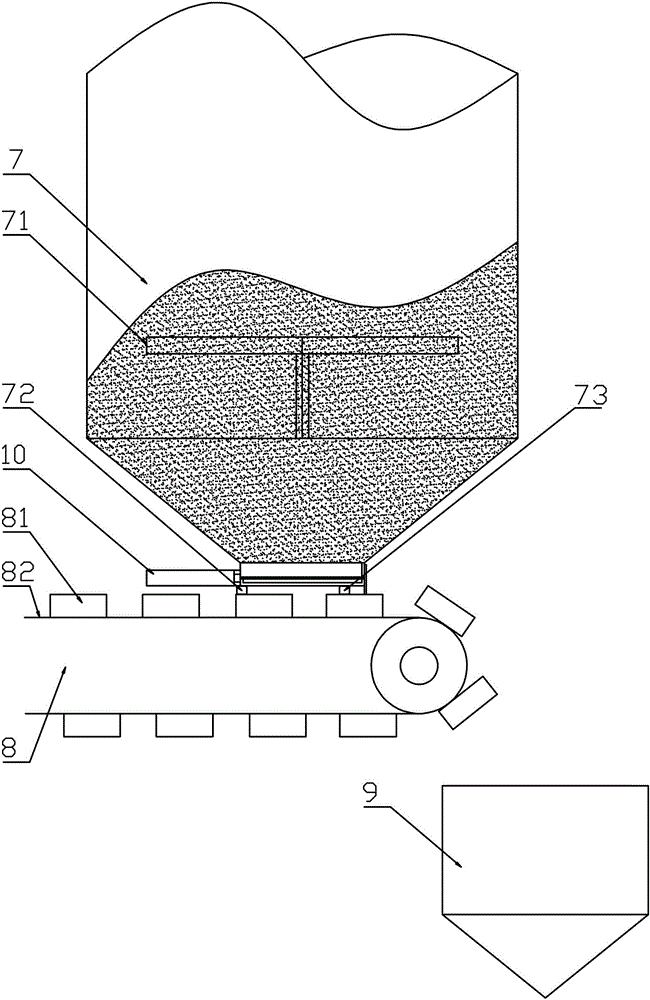

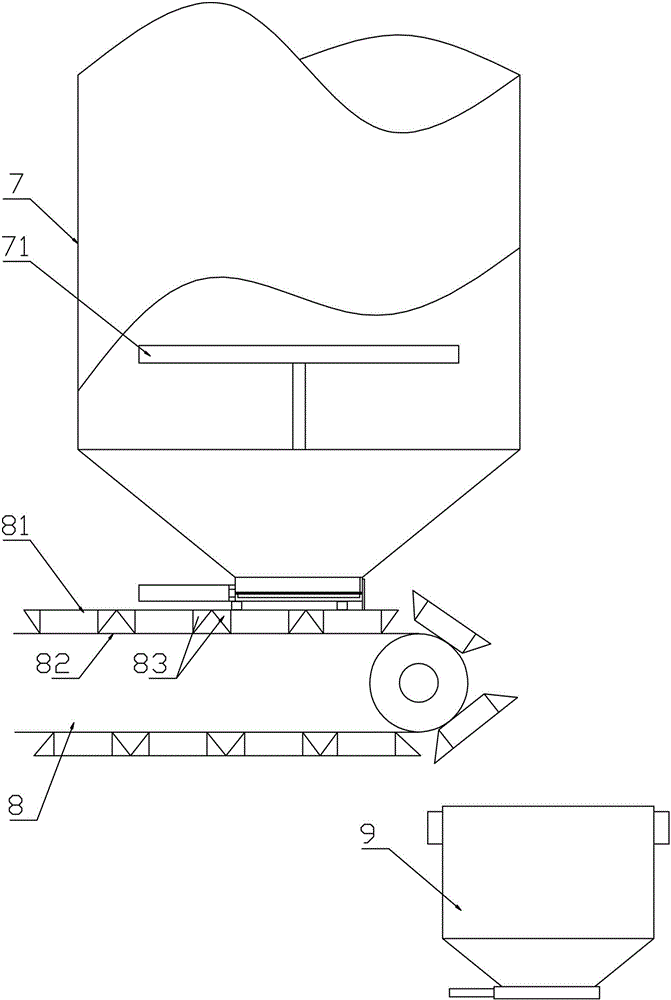

[0035] The bottom of the batching bin 7 is provided with a batching conveyor 8 controlled by an electric control device 14 for feeding spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com