Water jet dust collector

A vacuum cleaner and water jet technology, which is applied in the field of new vacuum cleaner devices, can solve the problems of air permeability affecting dust, small storage capacity, etc., and achieve good dust absorption effect, large dust collection capacity, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

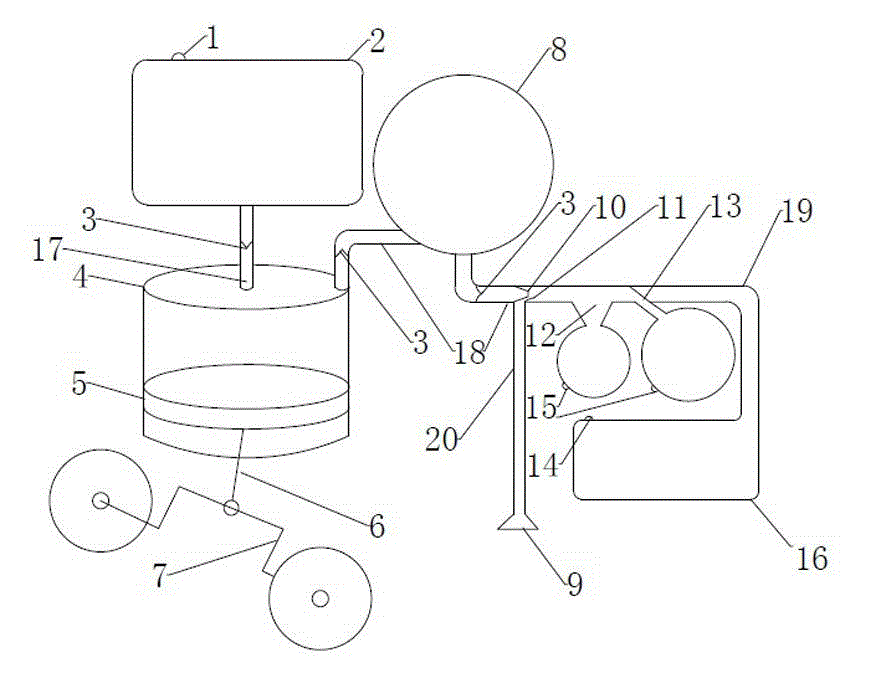

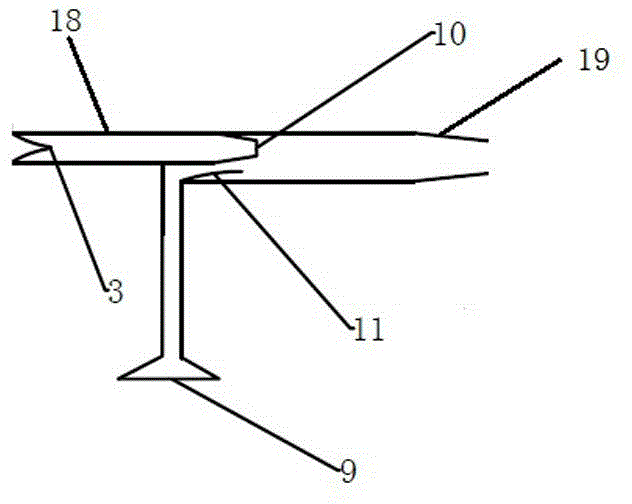

[0026] Such as figure 1 As shown, the water jet vacuum cleaner of the present invention consists of a water tank 2, an unpressurized clear water delivery pipe 17, three one-way valves 3, a booster chamber 4, a piston 5, a connecting rod 6, a crankshaft 7, two pressurized clear water delivery pipes 18. It consists of a pressure storage chamber 8, a dust suction conduit 20, a nozzle 10, a sewage delivery pipe 19, a vortex descaling chamber 12, a garbage recovery chamber 15, a filter screen 13, and a sewage collection chamber 16.

[0027] The top of the water tank 2 is provided with a ventilation hole 1, and the bottom of the water tank 2 communicates with the top of the booster chamber 4 through a pressure-free clean water delivery pipe 17. A check valve 3 is arranged in the pressure-free clean water delivery pipe 17, and the check valve 3 here is only Water is allowed to enter the plenum 4 from the tank 2 .

[0028] The piston 5 is arranged in the booster chamber 4, the cranks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com