Ceramsite sand drying device

A drying device and ceramsite sand technology are applied in the directions of drying, drying machine, drying gas arrangement, etc., which can solve the problems of poor drying effect and uneven heating, prevent uneven heating, and facilitate classification and collection. The effect of subsequent use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

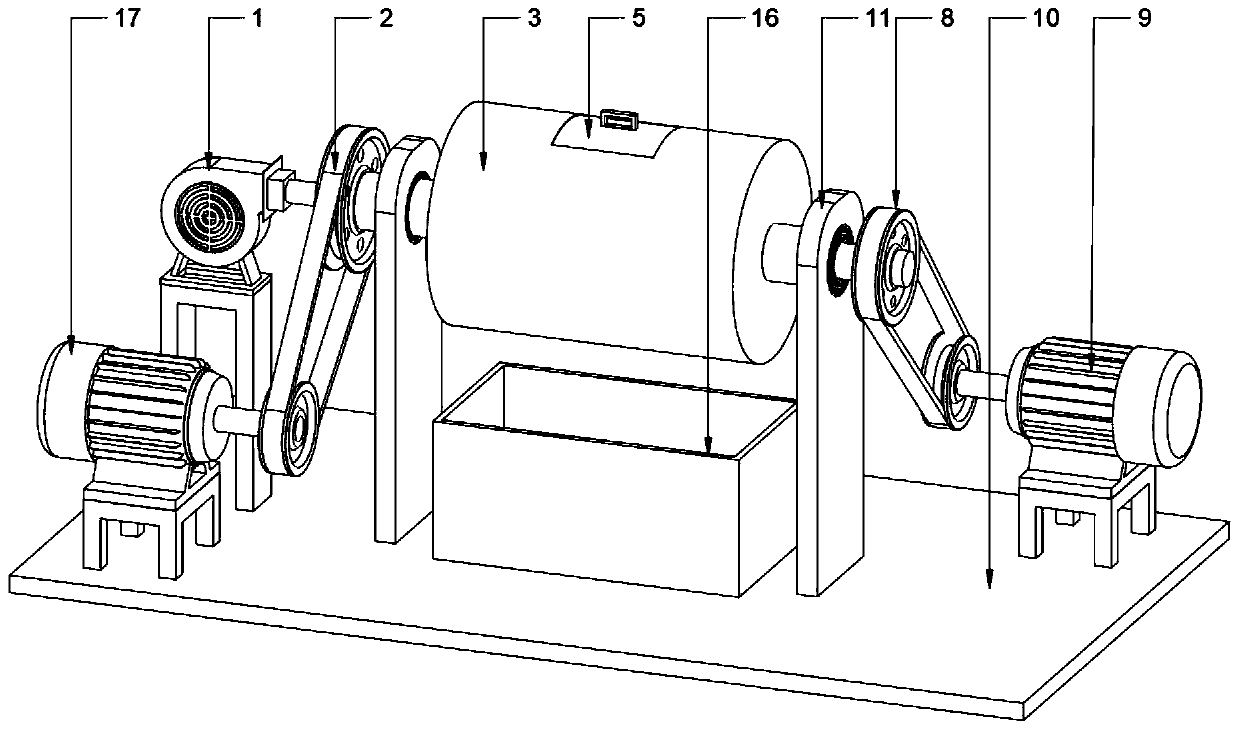

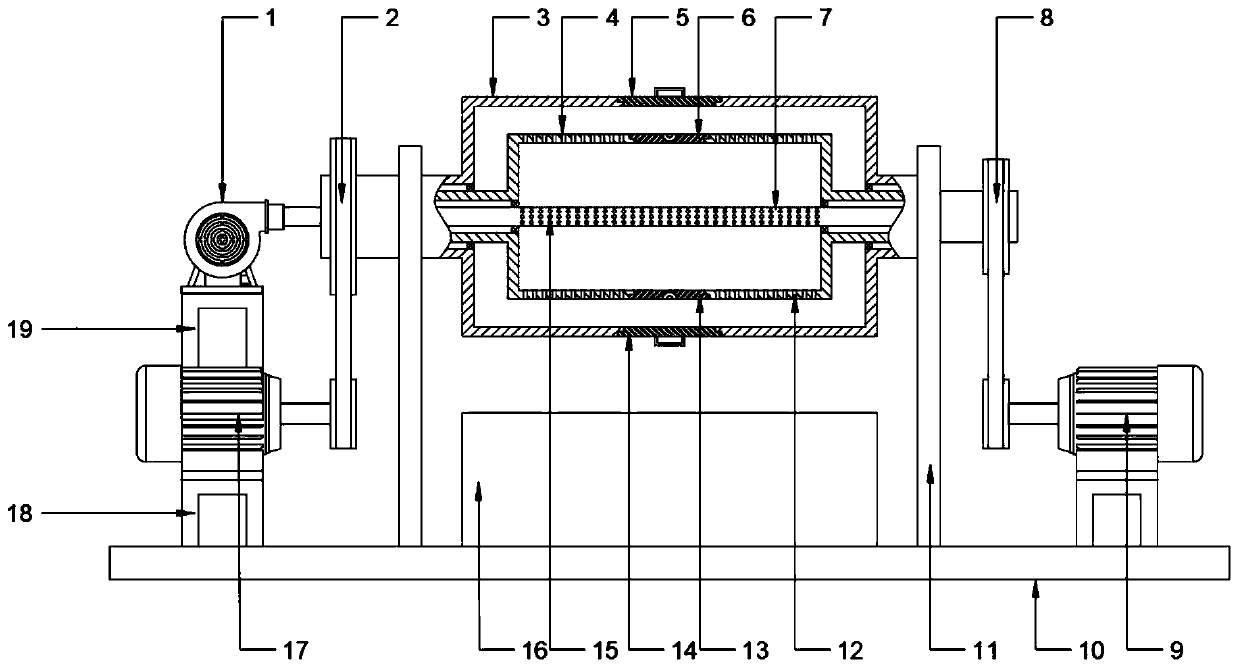

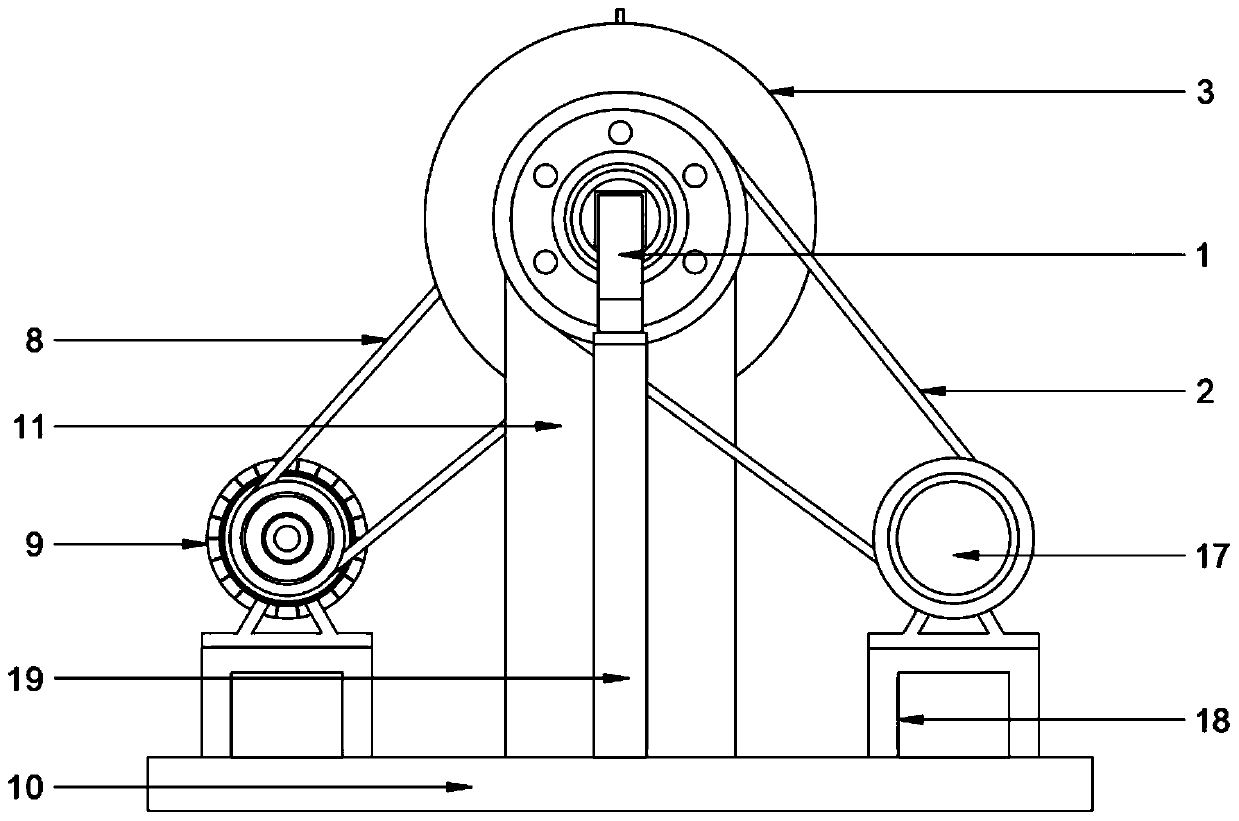

[0024] see Figure 1~4 , in an embodiment of the present invention, a ceramsite sand drying device includes a frame, a drum and a drying assembly installed on the frame, and the frame includes a bottom plate 10 and two groups of rollers fixedly arranged on the bottom plate 10 Support 11, the two ends of the drum are rotatably installed on the drum support 11, the upper and lower parts of the drum are respectively provided with a feed door and a discharge door, which are used for feeding and discharging respectively; one end of the drying assembly is provided It is at the axis position inside the drum and its other end passes through the drum and is fixedly connected with the fan support 19 fixedly arranged on the bottom plate 10; the power mechanism for driving the drum to rotate is also arranged on the frame.

[0025] Put the material into the drum through the feed door, close the feed door, start the power mechanism, and start the drying component at the same time, and use t...

Embodiment 2

[0032] see Figure 1~2 , in the embodiment of the present invention, a ceramsite sand drying device, in order to enhance the practicability of the device and facilitate the classification and collection of dried materials, on the basis of embodiment 1, the bottom plate 10 is still provided with storage Material box 16 and material storage box 16 are positioned at the first discharge door 14 below, and the quantity of described material storage box 16 is two groups; Open the first discharge door 14, the material in the first drum 3 is conveyed to a group of storage. In the material box 16, after collecting the materials in the first drum 3, replace another group of material storage boxes 16, open the second discharge door 13, and transport the materials in the second drum 4 to another group of material storage boxes 16 Inside, two groups of material storage boxes 16 are used to hold the materials in the first drum 3 and the second drum 4 respectively, which is convenient for cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com