Gas solubility jet flow generator

A generation device and gas-soluble technology, applied in the field of jet flow, can solve the problems of large water consumption of jet flow, low energy utilization rate, complex device structure, etc., and achieve the effect of high jet flow speed, promoting uniform gas-liquid mixing, and uniform gas-liquid mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

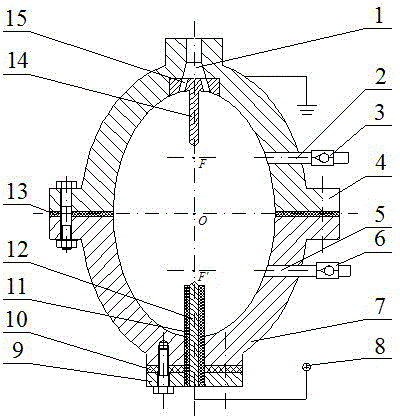

[0030] An aerosol jet generating device. Such as figure 1 As shown, the device consists of the generator upper hemisphere 4 and the generator lower hemisphere 7 fixedly connected by bolts to form a hollow ellipsoid; an intermediate sealing ring 13 is provided between the generator upper hemisphere 4 and the generator lower hemisphere 7, and the generator upper hemisphere 4 And the length ratio of the semi-major axis and the semi-minor axis of the lower hemisphere 7 of the generator is (1.2~2.0)︰1.

[0031] The end of the long semi-axis of the upper hemisphere 4 of the generator is provided with an upper boss, and the center of the upper boss is provided with a jet nozzle 1, the center line of the jet nozzle 1 coincides with the long semi-axis of the upper hemisphere 4 of the generator, and the port of the jet nozzle 1 The shape of the inner wall of the upper hemisphere 4 of the generator is successively a circular hole, a truncated cone hole and a reaming hole. The negative...

Embodiment 2

[0040] An aerosol jet generating device. Such as figure 1 As shown, the device consists of the generator upper hemisphere 4 and the generator lower hemisphere 7 fixedly connected by bolts to form a hollow ellipsoid; an intermediate sealing ring 13 is provided between the generator upper hemisphere 4 and the generator lower hemisphere 7, and the generator upper hemisphere 4 And the length ratio of the semi-major axis and the semi-minor axis of the lower hemisphere 7 of the generator is (2.0~2.5)︰1.

[0041] The end of the long semi-axis of the upper hemisphere 4 of the generator is provided with an upper boss, and the center of the upper boss is provided with a jet nozzle 1, the center line of the jet nozzle 1 coincides with the long semi-axis of the upper hemisphere 4 of the generator, and the port of the jet nozzle 1 The shape of the inner wall of the upper hemisphere 4 of the generator is successively a circular hole, a truncated cone hole and a reaming hole. The negative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com