A feeding device for a large-diameter circular machine for piston rings

A technology of feeding device and piston ring, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of uncoordinated operation, increased production cost of manufacturers, large amount of waste, etc. The effect of precision and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

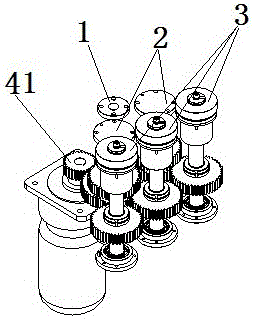

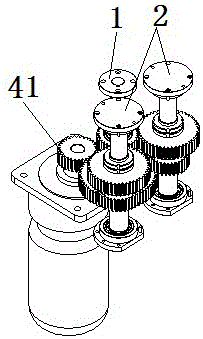

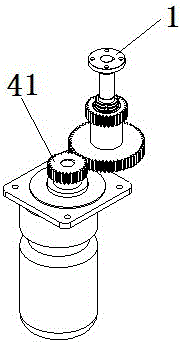

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a large-diameter circular machine feed device for piston rings is composed of a main transmission shaft assembly 1 , two bridge shaft assemblies 2 , and three positioning shaft assemblies 3 . The main transmission assembly 1 includes a main transmission shaft 12, a fixed cover 13 and a main transmission gear 11 sleeved on the main transmission shaft 12, and the fixed cover 13 and the main transmission gear 11 are respectively arranged at the upper and lower ends of the main transmission shaft , the main transmission gear 11 adopts a double gear, and the double gear includes a larger first gear 111 and a smaller second gear 112 . The bridge shaft assembly 2 includes a bridge shaft 22 and an upper bearing seat 21 sleeved on the bridge shaft 22, a lower bearing seat 26 and a bridge gear, and the upper bearing seat 21 and the lower bearing seat 26 are respectively arranged on The two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com