A kind of preparation method of polycarboxylate water reducer

A technology of water reducing agent and polycarboxylic acid, applied in the field of preparation of polycarboxylate water reducing agent, can solve the problems of large difference, uneven distribution, poor product performance, etc., achieve stable and complete reaction, improve adaptability, Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

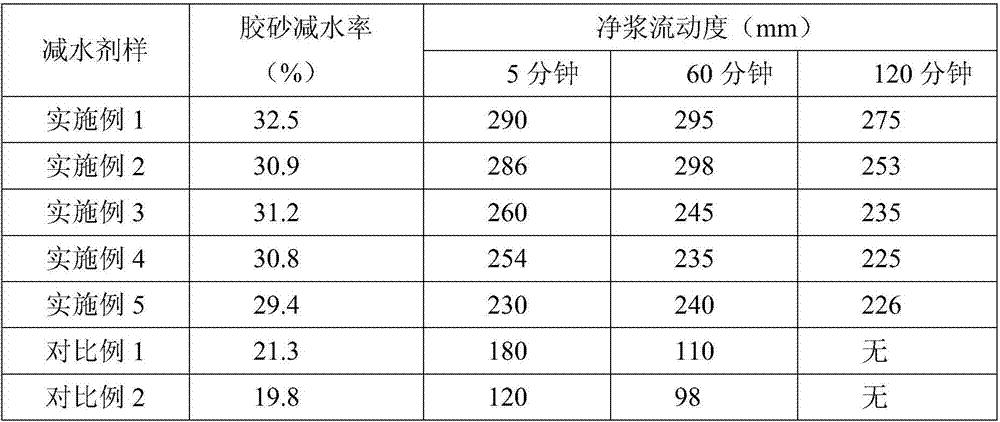

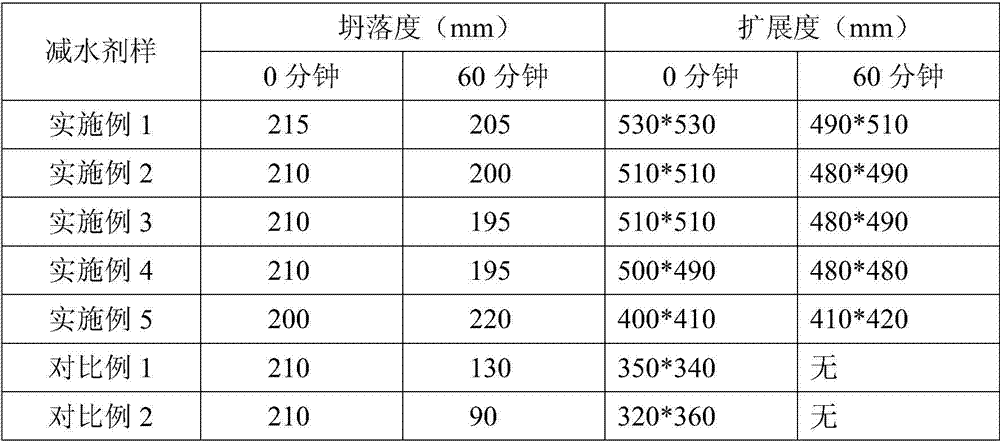

Examples

Embodiment 1

[0043] Preparation of material A: Add 300 grams of deionized water with a conductivity of 10 μs / cm and a temperature of 15°C into the reaction vessel, add 6.16 grams of acetic acid and 1.28 grams of gluconic acid and stir well, then add 288 grams of TPEG3600 and stir well, and finally add 2.88 grams Vinyl acetate was stirred evenly, and then the air in the reaction vessel was replaced by nitrogen gas to obtain material A with a temperature of 15° C. and a pH value of 4.1.

[0044] Preparation of material B: Add 19.5 g of acrylic acid to 40 g of deionized water with a conductivity of 10 μs / cm and a temperature of 15°C and stir evenly, then add 2.37 g of 27.5% hydrogen peroxide and stir evenly to prepare material B at a temperature of 15°C.

[0045] Preparation of material C: Add 0.87 g of thioglycolic acid to 30 g of deionized water with a conductivity of 10 μs / cm and stir evenly, then add 0.84 g of ascorbic acid and stir evenly to prepare material C at a temperature of 15° C. ...

Embodiment 2

[0049] Preparation of material A: Add 200 grams of deionized water with a conductivity of 20 μs / cm and a temperature of 10°C into the reaction vessel, add 5.76 grams of acrylic acid and stir evenly, then add 192 grams of TPEG2400 and stir evenly, finally add 0.192 grams of vinyl acetate, and stir After uniformity, nitrogen gas was introduced to replace the air in the reaction vessel to obtain material A with a temperature of 10° C. and a pH value of 3.9.

[0050] Preparation of material B: Add 10.9 grams of acrylic acid, 4.3 grams of methacrylic acid, and 2.0 grams of ethyl acrylate to 40 grams of deionized water with a conductivity of 20 μs / cm and a temperature of 10°C and stir evenly, then add 4.38 grams of ammonium persulfate and stir evenly , to obtain material B at a temperature of 10°C.

[0051] Preparation of material C: add 0.55 g of mercaptoacetic acid, 0.21 g of mercaptopropionic acid and 0.23 g of sodium methacrylate to 30 g of deionized water with a conductivity of...

Embodiment 3

[0055] Preparation of material A: Add 200 grams of deionized water with a conductivity of 20 μs / cm and a temperature of 5°C into the reaction vessel, add 2.96 grams of propionic acid, 3.84 grams of citric acid, 1.96 grams of gluconic acid and 0.86 grams of methacrylic acid and stir evenly. Then add 192 grams of HPEG2400 and stir evenly, and finally add 1.92 grams of vinyl acetate, stir evenly, and then pass nitrogen into the reaction vessel to replace the air in the reaction vessel to obtain material A with a temperature of 5° C. and a pH value of 3.8.

[0056] Preparation of material B: Add 20.3 grams of acrylic acid to 40 grams of deionized water with a conductivity of 20 μs / cm and a temperature of 5°C and stir evenly, then add 1.2 grams of 27.5% hydrogen peroxide and stir evenly, and finally add 1.0 grams of ammonium persulfate and potassium persulfate 0.8 g was stirred evenly to obtain material B at a temperature of 5°C.

[0057] Preparation of material C: Add 0.68 g of me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com