A nano-bonding agent, a diamond composite pick made of the binder, and a method for preparing the composite pick

A composite pick and diamond technology, applied in the field of preparation of diamond composite picks and diamond composite picks, can solve the problem of difficult to form effective cutting on asphalt concrete pavement, easy blunt tooth heads, and tooth head wear of cemented carbide picks Fast and other problems, to achieve the effect of good sintering promotion, increase volume ratio, enhance wear resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A nano-bonding agent is composed of the following raw materials in weight percentage: Co powder (18-22nm) 95%, TiC powder (35-40nm) 3%, Si powder (35-40nm) 2%.

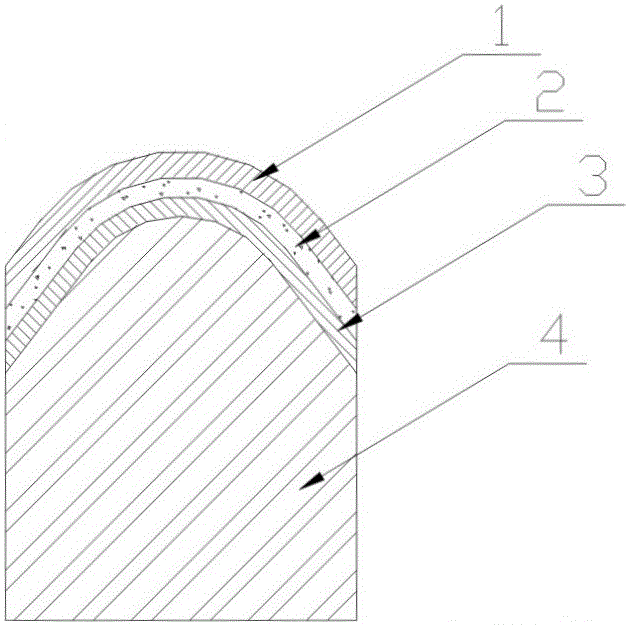

[0030] A kind of diamond composite cutting tooth made by above-mentioned nano bonding agent, as figure 1 As shown, it includes a cemented carbide button base 4 and a second transition layer 3 , a first transition layer 2 and a diamond polycrystalline layer 1 sequentially arranged on the base 4 . The weight percent of each layer is: 55% of the diamond polycrystalline layer, 20% of the first transition layer and 25% of the second transition layer. The raw material composition of the diamond polycrystalline layer is: 93wt% of diamond powder (15-35μm) and 7wt% of nano-bonding agent. The raw material composition of the first transition layer is: diamond powder (8-12 μm) 55wt%, tungsten carbide powder (1.0-1.2 μm) 35wt%, nano-bonding agent 10wt%. The raw material composition of the second transition layer is: diamo...

Embodiment 2

[0040] A nano-bonding agent is composed of the following raw materials in weight percentage: 99% of Co powder (18-22nm), 0.5% of TiC powder (35-40nm), and 0.5% of Si powder (35-40nm).

[0041] A diamond composite pick made of the above-mentioned nano-bonding agent, comprising a cemented carbide button substrate and the second transition layer, the first transition layer and the polycrystalline diamond layer arranged on the substrate in sequence, the weight percentage of each layer is : Diamond polycrystalline layer 65%, the first transition layer 15% and the second transition layer 20%. The raw material composition of the diamond polycrystalline layer is: 97wt% of diamond powder (15-35μm) and 3wt% of nano-bonding agent. The raw material composition of the first transition layer is: diamond powder (8-12 μm) 65wt%, tungsten carbide powder (1.0-1.2 μm) 30wt%, nano-bonding agent 5wt%. The raw material composition of the second transition layer is: diamond powder (4-6 μm) 35wt%, t...

Embodiment 3

[0051] A nano-bonding agent is composed of the following raw materials in weight percentage: Co powder (18-22nm) 97%, TiC powder (35-40nm) 2%, Si powder (35-40nm) 1%.

[0052] A diamond composite pick made of the above-mentioned nano-bonding agent, comprising a cemented carbide button substrate and the second transition layer, the first transition layer and the polycrystalline diamond layer arranged on the substrate in sequence, the weight percentage of each layer is : Diamond polycrystalline layer 60%, the first transition layer 18% and the second transition layer 22%. The raw material composition of the diamond polycrystalline layer is: 95wt% of diamond powder (15-35μm) and 5wt% of nano-bonding agent. The raw material composition of the first transition layer is: diamond powder (8-12 μm) 60wt%, tungsten carbide powder (1.0-1.2 μm) 32wt%, nano-bonding agent 8wt%. The raw material composition of the second transition layer is: 30wt% of diamond powder (4-6μm), 58wt% of tungste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com