A construction method of drainage type asphalt pavement

A technology of asphalt pavement and construction method, applied in the direction of roads, roads, pavement details, etc., can solve unsolved problems and other problems, achieve the effect of reducing splashing water and water mist, reducing road noise, and maintaining visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

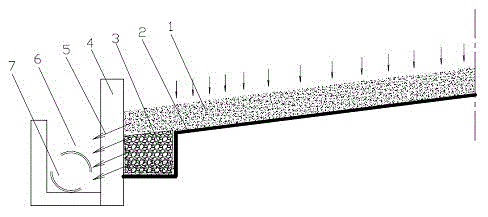

[0024] The basic structure of the drainage asphalt pavement in this embodiment is as follows: figure 1 As shown, the pavement layer 1 is a drainage asphalt pavement layer with a thickness of 5-8cm and a porosity of 18%-25%, and has a drainage slope greater than 1.5% (preferably controlled at 1.5%-3%). Water barrier layer 2 with a thickness of 15-20mm is 0.3-0.5kg / m 2 The modified emulsified asphalt is used to separate the pavement layer 1 from the foundation. The lower part of both sides of the pavement layer 1 has a water collection layer 3 with a thickness of 15-20 cm and a porosity of 35%-40%. 6 connected. The bottom of the gutter 6 is lower than the catchment layer 3 . The side of the gutter 6 adjacent to the road surface is a curb 4 made of concrete, and a drainpipe 7 is arranged in the ditch. Both sides of the water-resistant layer 2 respectively extend from the bottom of the water-collecting layer 3 to the water-collecting ditch 6 . The water collecting ditch 6 is ...

Embodiment 2

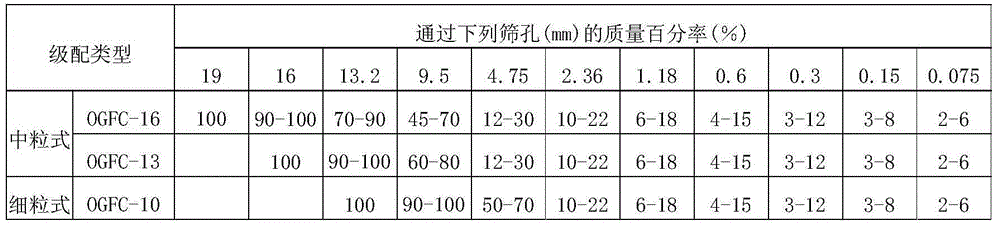

[0032] The basic situation of this embodiment is basically the same as that of Embodiment 1, the difference is that: the drainage asphalt pavement layer is about 5 cm, and a pavement cushion with a thickness of about 3 cm is also laid between the water-resistant layer, and the pavement cushion is graded according to the following mass percentages Mixed gravel: 100% pass through 16mm sieve, 90-100% pass through 13.2mm sieve, 60-80% pass through 9.5mm sieve, 12-30% pass through 4.75mm sieve, 10-22% pass through 2.36mm sieve Hole, 6-18 through 1.18mm sieve, 4-15% through 0.6mm sieve, 3-12% through 0.3mm sieve, 3-8% through 0.15mm sieve, 2-6% through 0.075mm sieve , so its void ratio is greater than that of the drainage asphalt pavement layer. In this way, the water seepage and drainage effect are better.

[0033] In the rolling process, 2-3 times of initial pressing at a speed of 1.5-2km / h, 6-8 times of re-pressing at a speed of 4-5km / h, and 2-3 times of final pressing at a spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com