Compound rubber ball shock absorption support for bridge

A technology of composite rubber and shock-absorbing bearings, which is applied in bridges, bridge construction, bridge parts, etc., can solve the problems of inability to exert shock absorption and isolation, limited shear deformation capacity, etc., achieve excellent shock absorption and isolation effects, and reduce earthquakes Weight, the effect of increasing the vertical bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

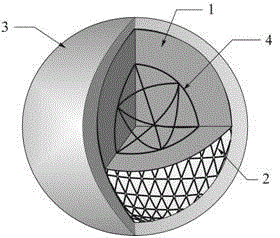

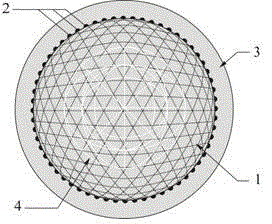

[0028] Example 1: see figure 1 , figure 2 , image 3 and Figure 4 , Composite rubber ball bridge shock absorption bearing, composed of internal composite rubber ball 1, high-strength rope net 2 and external rubber ball shell 3.

[0029] As one of the technical points of the present invention, the internal composite rubber ball 1 is a solid spherical body, and the interior contains internal restraint fibers 4 that are presented according to certain rules. Movement is isotropic.

[0030] As one of the technical points of the present invention, the high-strength rope net 2 is made of high-strength steel wire, or high-strength fiber and other materials with strong tensile strength.

[0031] As one of the technical points of the present invention, the high-strength rope net 2 is woven into a triangular mesh with isotropic restraint capability, and the inner compound rubber ball 1 is tightly wrapped in space.

[0032] As one of the technical points of the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com