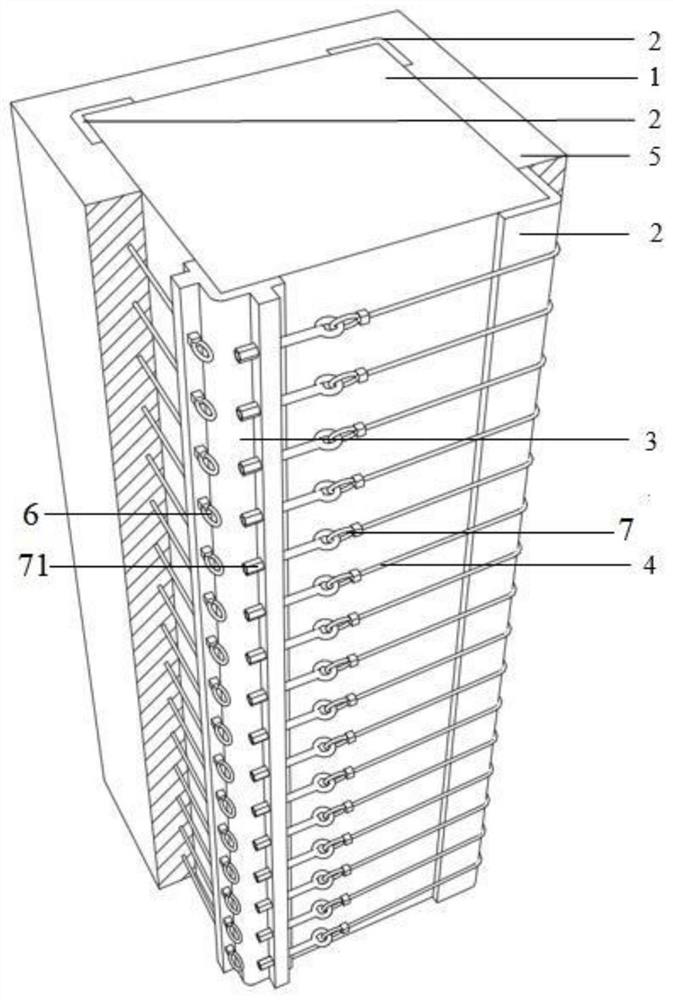

A self-locking ecc-clad reinforced concrete column reinforcement method

A reinforced concrete column, self-locking technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of poor high temperature resistance, fire resistance, performance impact, occupied building area, etc., to achieve good chloride ion penetration resistance, Obvious anti-cracking effect and effect of constraining lateral deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

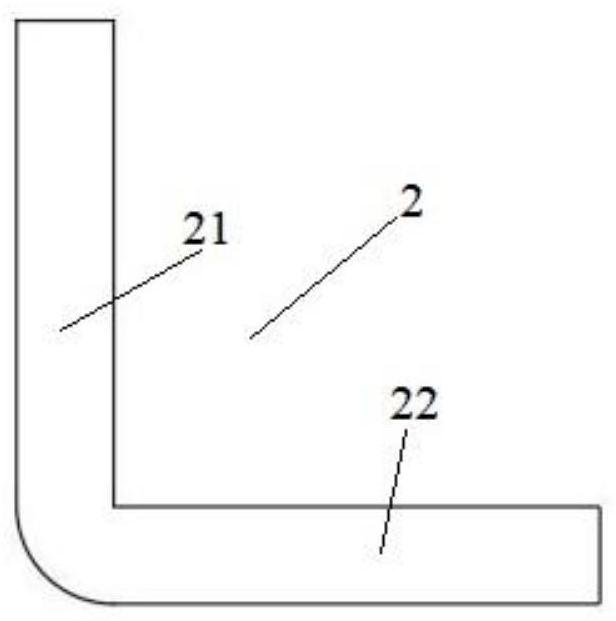

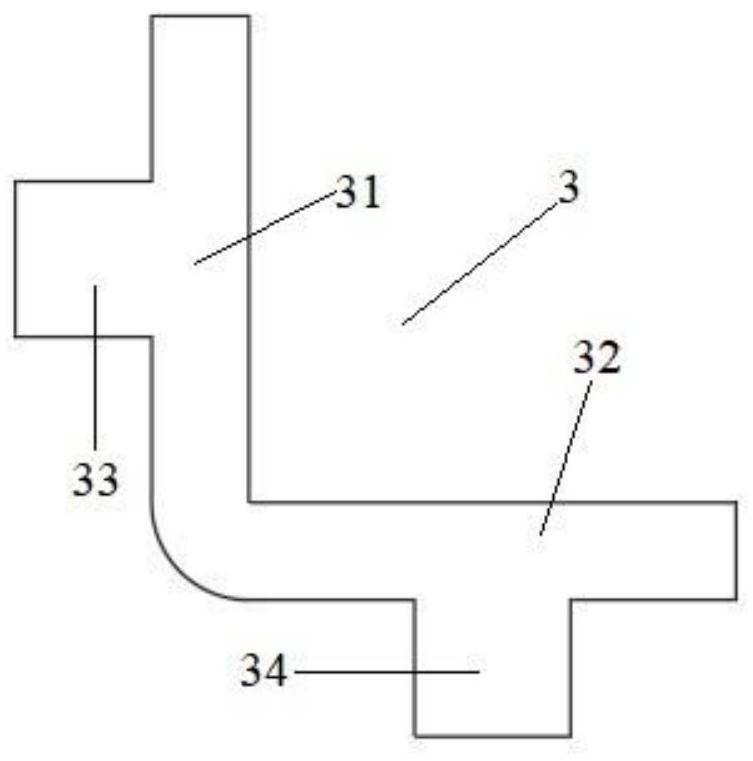

Embodiment 1

[0061] The thickness of the first angle steel 2 and the second angle steel 3 is 4 mm, and the side length of the first rectangular steel plate 21 , the second rectangular steel plate 22 , the third rectangular steel plate 31 and the fourth rectangular steel plate 32 is 30 mm. Steel strand 4 adopts high-strength steel strand 4, and the diameter of steel strand 4 is 6mm, and tensile strength is 1860MPa, and ultimate tensile strain is 2%, and the spacing of adjacent steel strand 4 in the steel strand network is 30mm, steel The prestress level of the stranded wire 4 is 30%, and the prestress is applied by tightening the round hole bolt 71 at the end. ECC5 is made by mixing cement, fly ash, fine sand, silica fume, water, PVA fiber, water reducer, accelerator, etc., and the corresponding specific gravity is cement: fly ash: fine sand: silica fume: water: PVA fiber : Water reducer: Accelerator = 1: 2: 1.2: 0.05: 0.9: 0.05: 0.01: 0.01. The thickness of ECC5 is 25mm, its tensile stren...

Embodiment 2

[0063] The thickness of the first angle steel 2 and the second angle steel 3 is 5 mm, and the side length of the first rectangular steel plate 21 , the second rectangular steel plate 22 , the third rectangular steel plate 31 and the fourth rectangular steel plate 32 is 36 mm. Steel strand 4 adopts high-strength steel strand 4, and the diameter of steel strand 4 is 8mm, and tensile strength is 1770MPa, and ultimate tensile strain is 2%, and the spacing of adjacent steel strand 4 in the steel strand net is 50mm, steel The prestress level of the stranded wire 4 is 30%, and the prestress is applied by tightening the round hole bolt 71 at the end. ECC5 is made by mixing cement, fly ash, fine sand, silica fume, water, PVA fiber, water reducer, accelerator, etc., and the corresponding specific gravity is cement: fly ash: fine sand: silica fume: water: PVA fiber : Water reducer: Accelerator = 1: 0.8: 1.2: 0.02: 0.5: 0.04: 0.008: 0.01. The thickness of ECC5 is 35mm, its tensile streng...

Embodiment 3

[0065] The thickness of the first angle steel 2 and the second angle steel 3 is 5 mm, and the side length of the first rectangular steel plate 21 , the second rectangular steel plate 22 , the third rectangular steel plate 31 and the fourth rectangular steel plate 32 is 50 mm. Steel strand 4 adopts high-strength steel strand 4, and the diameter of steel strand 4 is 15.2mm, and tensile strength is 2100MPa, and ultimate tensile strain is 3.5%, and the spacing of steel strand 4 in the steel strand net is 50mm, and steel strand The prestress level of line 4 is 30%, and the prestress is applied by tightening the round hole bolt 71 at the end. High-ductility cement-based composite is made by mixing cement, fly ash, fine sand, silica fume, water, PVA fiber, water reducing agent, accelerator, etc., and the corresponding specific gravity is cement: fly ash: fine sand: silica fume: Water: PVA fiber: water reducer: accelerator = 1:3:1.4:0.02:1.1:0.08:0.015:0.01. The thickness of ECC5 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com