Construction method of corrugated steel plate bridge covered with soil based on crushed stone grouting filling layer

A technology of corrugated steel plates and construction methods, which is applied in the direction of infrastructure engineering, bridges, arch bridges, etc., can solve the problems of economical and construction convenience discounts, high requirements for on-site construction, and poor mechanical performance, and achieve processing and on-site assembly Convenience, ensuring structural stability and integrity, and low construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

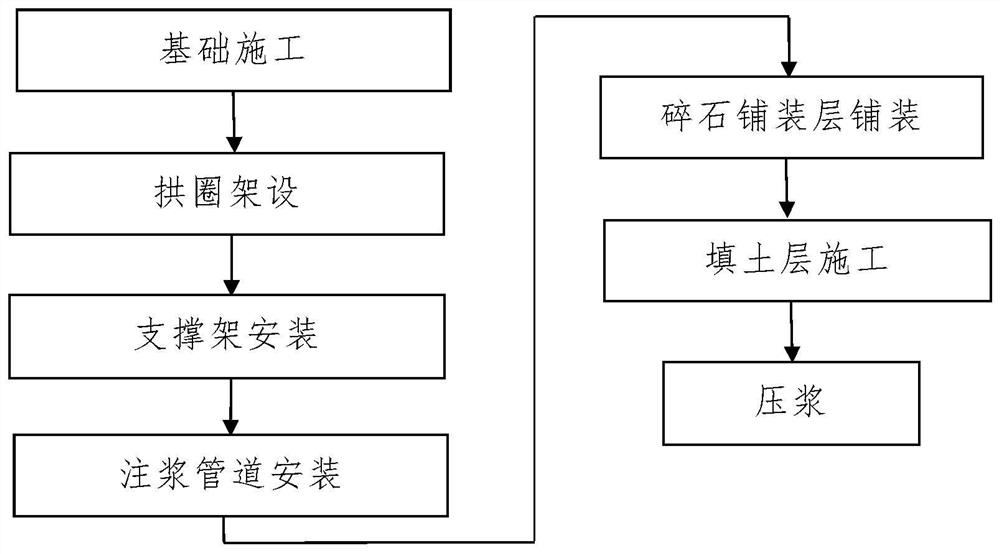

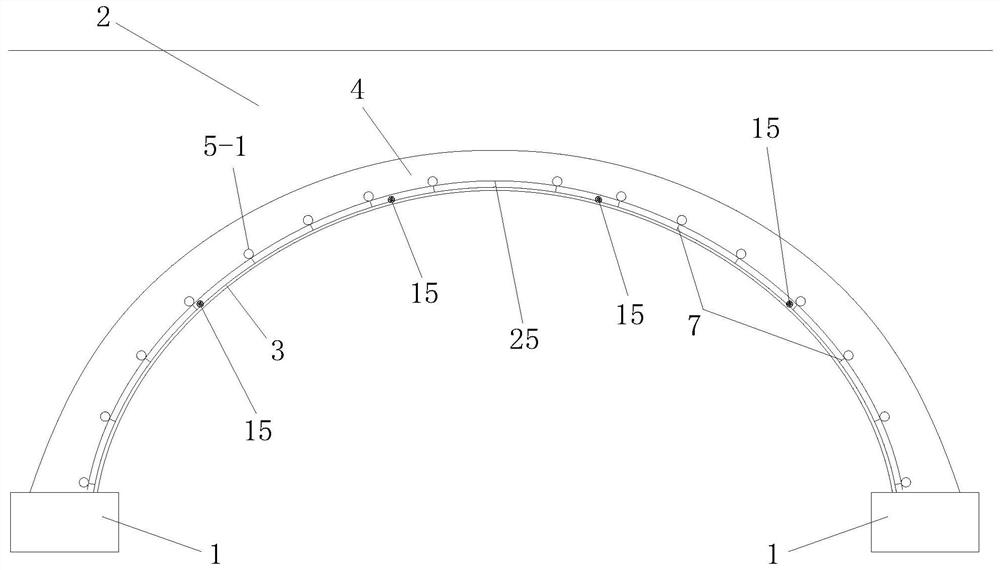

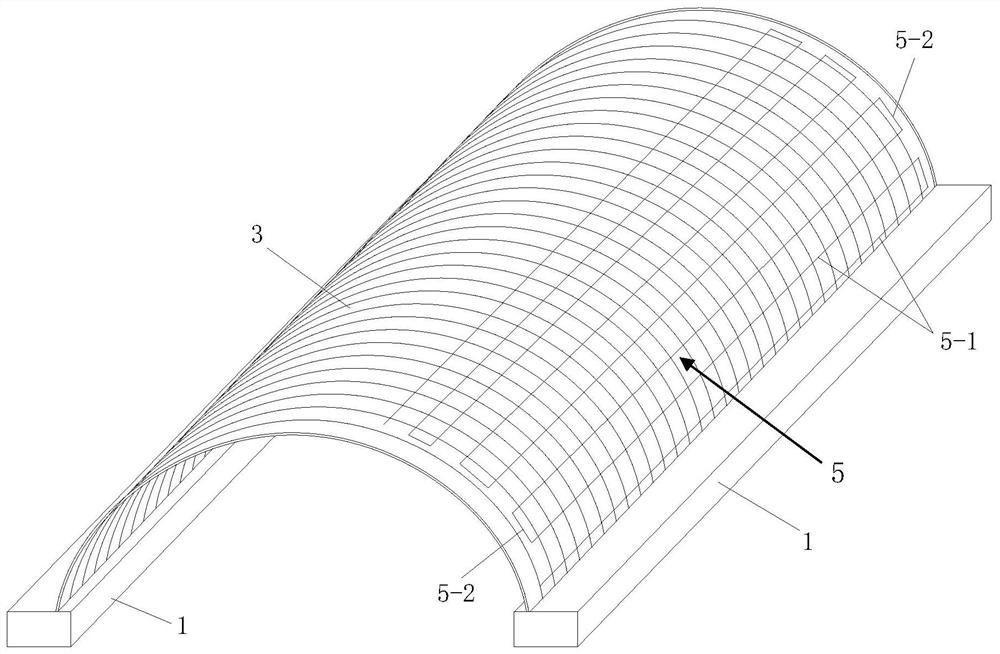

[0078] Such as figure 1 A construction method of a corrugated steel plate bridge covered with soil based on gravel grouting filling layer is shown, combined with figure 2 , image 3 , Figure 4 , Figure 5 and Figure 12 The corrugated steel plate bridge covered with soil includes two concrete foundations 1 at the front and back, a main arch erected between the two concrete foundations 1, and a filling layer 2 covering the outside of the main arch. The two concrete foundations 1 are laid horizontally and the two are laid on the same horizontal plane, and the two concrete foundations 1 are laid in parallel and both are laid along the direction of the bridge;

[0079] The main arch is arranged horizontally and includes a load-bearing arch ring 3 and a crushed stone grouting filling layer 4 arranged on the load-bearing arch ring 3, and the crushed stone grouting filling layer 4 is arranged between the load-bearing arch ring 3 and the filling layer 2, the bottoms of the fron...

Embodiment 2

[0254] Such as Figure 23 As shown, in this embodiment, the difference from Embodiment 1 is: m=6. During actual construction, the value of m can be adjusted according to specific needs. The four arch ring splicing sections 11 in the load-bearing arch ring 3 are respectively the left end splicing section, the second splicing section, the third splicing section and the right end splicing section from left to right.

[0255] In this embodiment, the rest of the method steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com