Unequal-strength wall beam joint based on steel plate hoop confined concrete composite short column

A technology for constraining concrete and steel plate hoop, applied in building components, earthquake resistance, building types, etc., can solve the problems of insufficient vibration, affecting quality, low concrete strength, etc., to improve seismic performance, reduce construction difficulty, and improve bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

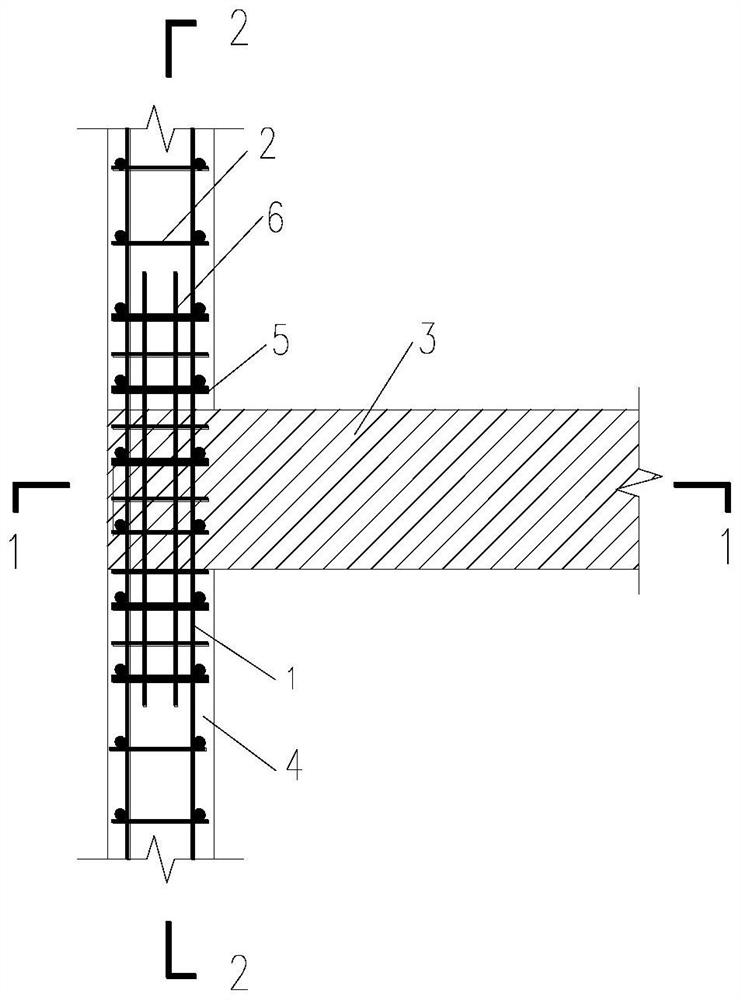

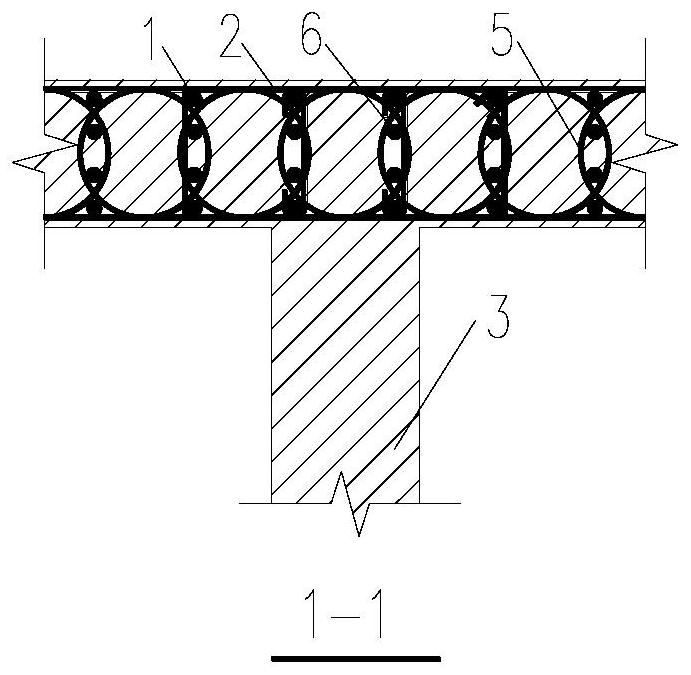

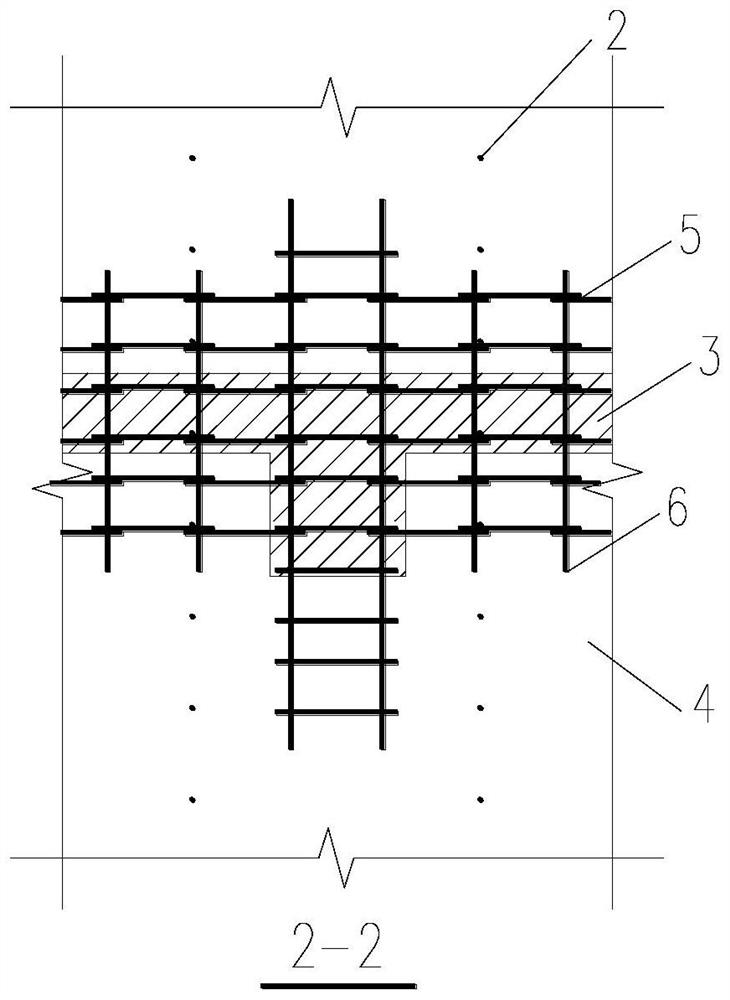

[0028] see Figure 1~4 , a unequal-strength wall beam joint based on steel plate hoop-constrained concrete laminated short columns, including wall vertical reinforcement 1, wall stirrup 2, first-strength grade concrete 3, second-strength grade concrete 4, steel plate stirrup 5 and short vertical ribs6. It should be noted that in the field of building construction, the second strength grade concrete 4 is higher strength grade concrete, and the first strength grade concrete 3 is lower strength grade concrete.

[0029] In the embodiment of the present invention, the steel plate hoop 5 can be in two forms: a single steel hoop or a double steel hoop formed by welding steel plates.

[0030] In the embodiment of the present invention, the steel plate hoops 5 and short vertical ribs 6 are built into the concrete 3 of the first strength level at the intersection of nodes, distributed along the wall height direction and extending into the upper and lower walls, and the upper and lower ...

Embodiment 2

[0033] see Figure 1~4 , a unequal-strength wall-beam joint based on steel plate hoop-constrained concrete laminated short columns, including

[0034] Concrete wall, which constitutes the main structure of the wall-beam joint, and it is composed of the first strength grade concrete 3 formed by horizontal pouring, and the second strength grade concrete 4 vertically poured on the upper and lower sides of the first strength grade concrete 3 respectively ;

[0035] Wall vertical reinforcement 1, which is vertically buried inside the concrete wall of the wall beam node, and it is provided with several reinforcement cages bound and fixed by wall stirrups 2 to form the wall;

[0036] Steel plate hoop-constrained concrete laminated short columns, which are arranged in the reinforcement cage formed by the wall vertical steel bars 1 and wall hoops 2 arranged longitudinally, and are composed of steel plate hoops 5 and short vertical bars 6;

[0037] Wherein, the steel plate hoop 5 is a...

Embodiment 3

[0042] A kind of unequal-strength wall beam joint based on steel plate hoop-constrained concrete laminated short columns, its construction method is as follows:

[0043] Step 1, according to the reinforcement diagram, the wall vertical reinforcement 1, the wall stirrup 2, the steel plate hoop 5 and the short vertical reinforcement 6 are bound and formed to form a reinforcement cage for the wall, wherein the first steel plate hoop 5 is bound to the On the wall stirrup 2, the short vertical rib 6 is bound on the steel plate hoop 5 again.

[0044] Step 2: According to the reinforcement diagram, the slab reinforcement, the beam longitudinal reinforcement, the beam stirrup, the joint core area stirrup, the steel plate hoop 5 and the short vertical reinforcement 6 are bound and formed to form the beam slab and the joint core area reinforcement cage.

[0045] Step 3, pouring the second strength grade concrete 4 of the lower wall.

[0046] Step 4, pouring concrete 3 of the first stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com