A mine-used frp grid-coal gangue-self-compacting concrete regenerated roof and its construction method

A technology of self-compacting concrete and recycled roof, which is applied in earth square drilling, mining equipment, shaft equipment, etc. It can solve the problems of easy corrosion of metal mesh, insufficient strength of plastic mesh, and inability to anchor, so as to improve shear strength and elastic modulus , Inhibition of non-uniform settlement, the effect of simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

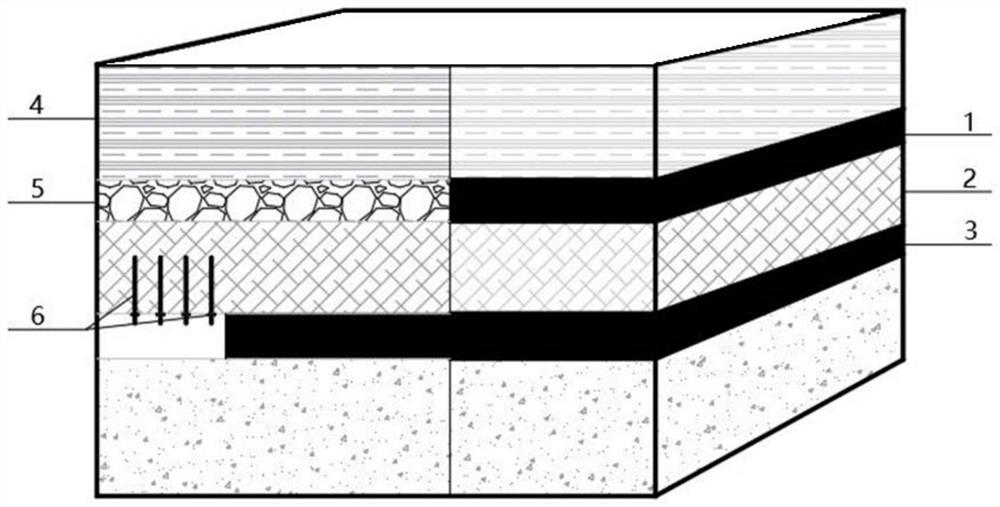

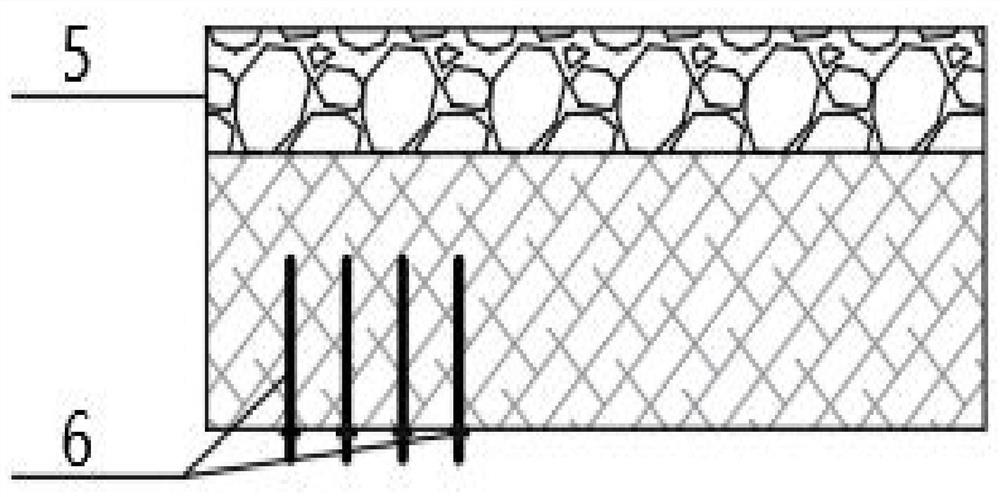

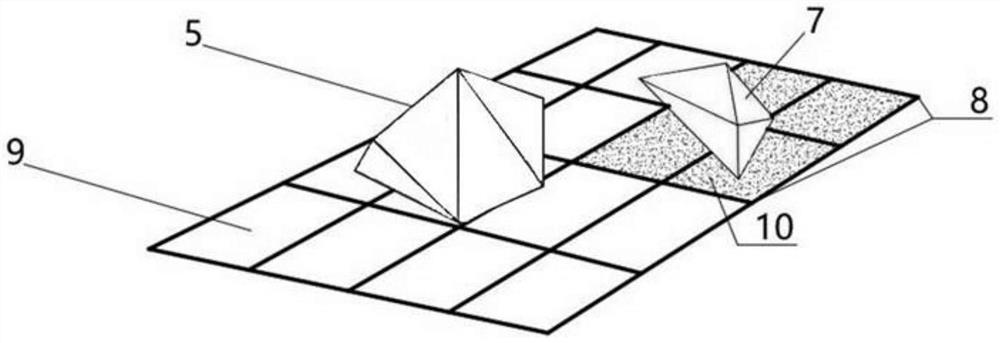

[0026] Such as Figure 1-4 As shown, a mine-used FRP grid-coal gangue-self-compacting concrete regenerated roof includes an upper layer 1, the upper end of the upper layer 1 is the overlying rock layer 4, and the lower end of the upper layer 1 is the reserved area rock layer 2. The lower end of the rock layer 2 in the reserved area is the lower layer 3, the anchor rod 6 is arranged between the rock layers 2 in the reserved area, the FRP grid 8 is installed at the bottom of the upper layer 1, and the artificially filled coal gangue 7 is installed at the upper end of the FRP grid 8. The upper end of the filled coal gangue 7 is provided with the second layer of FRP grid 8, and the upper end of the second layer of FRP grid 8 is provided with a second layer of artificially filled gangue 7, and the artificially filled coal gangue 7 is filled to the bottom of the overlying rock layer 4, and the FRP grid The grid 8 is provided with meshes 9, and the overlying rock layer 4 forms natura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com