Oil mass electronic sensor

An electronic sensor and oil quantity technology, applied in the field of oil quantity sensor, can solve the problems of poor anti-vibration strength of the reed switch, poor adaptability to ambient temperature, unfavorable energy conservation and environmental protection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is applied in the field of sensors, in particular, it refers to the field of oil quantity detection parts which are mainly used in various types of oil vehicles. The fuel quantity electronic detection sensor, especially the fuel quantity detection sensor for all kinds of automobiles working in the ambient temperature of -40°C to +85°C, is made on the basis of the existing oil quantity detection sensors used by various types of automobiles. Significant improvement has very important practical significance.

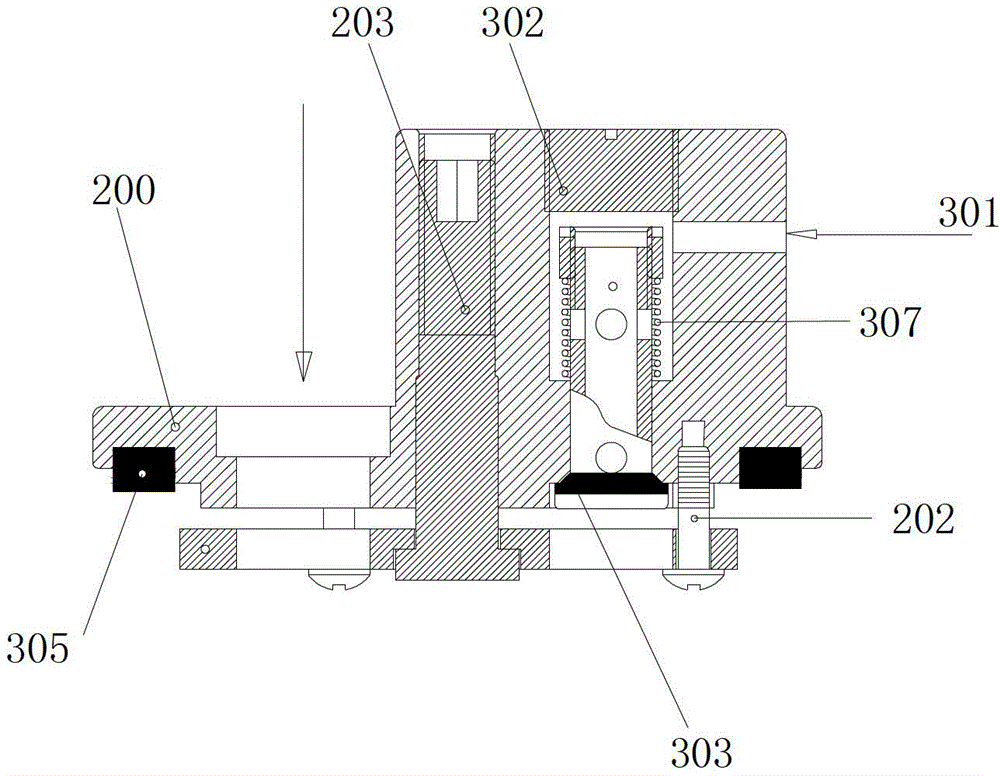

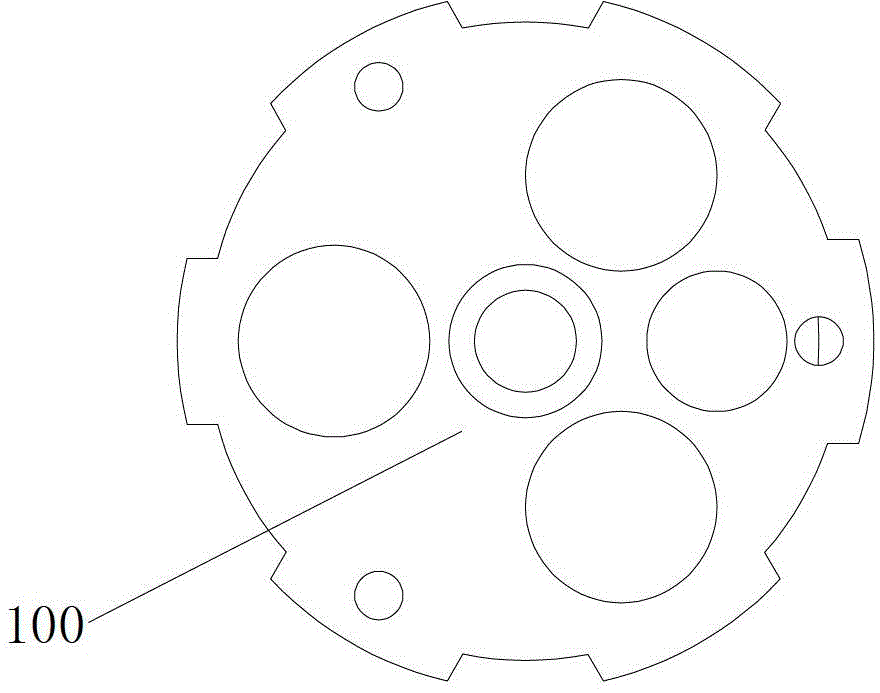

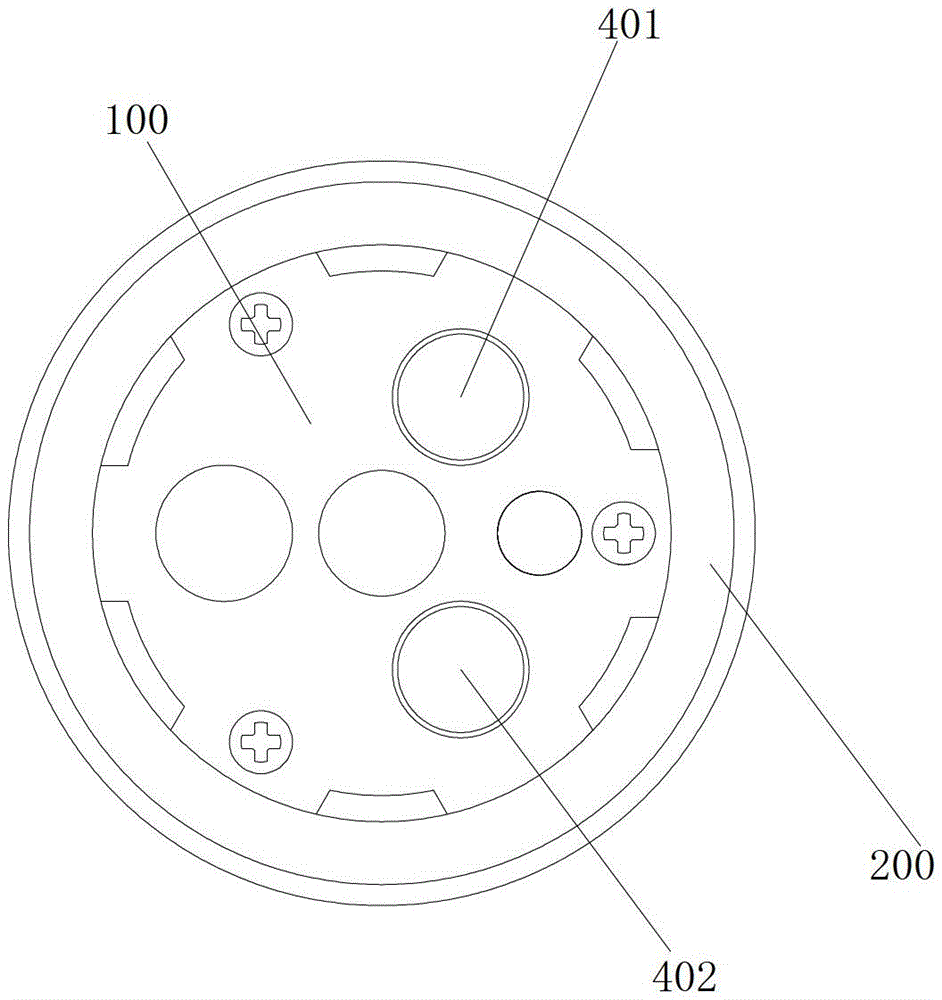

[0026] like Figure 1-5 As shown, the present invention provides a combination of one, two and three tubes, an energy-saving non-contact electric heating automatic oil quantity electronic sensor. It includes double and single-tube non-contact oil level electronic sensors, hereinafter referred to as oil level electronic sensor 600 .

[0027] Its technical solution is as follows: an electronic oil quantity sensor, which includes: double and sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com