Thermocouple high-temperature testing system

A test system and thermocouple technology, applied to thermometers, thermometers, and measuring devices that use directly heat-sensitive electric/magnetic components, can solve the problem of poor temperature measurement accuracy, low measurement accuracy, and poor operation reliability. problems, to achieve the effect of simple and reliable operation, precise measurement, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The thermocouple high-temperature testing system provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

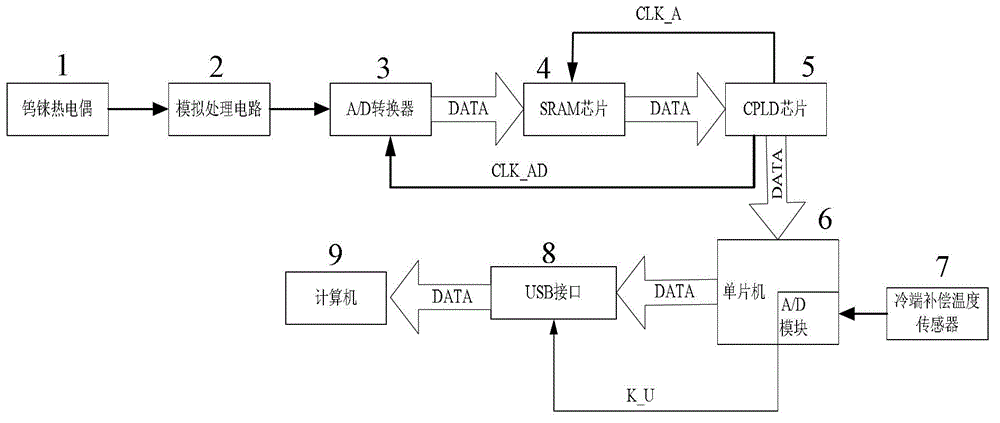

[0019] Such as figure 1 As shown, the thermocouple high-temperature test system provided by the present invention includes: tungsten-rhenium thermocouple 1, analog processing circuit 2, A / D converter 3, SRAM chip 4, CPLD chip 5, single-chip microcomputer 6, cold junction compensation temperature sensor 7, USB interface 8 and computer 9; Wherein:

[0020] Tungsten-rhenium thermocouple 1 is a temperature sensor installed in a high-temperature test environment, which is connected to an analog processing circuit 2 for collecting temperature signals;

[0021] The analog processing circuit 2 is an acquisition signal input processing circuit, which is connected with the A / D converter 3; since the voltage range of the output signal of the tungsten-rhenium thermocouple 1 is 0-37.107mV, acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com