Bolt tightening force coefficient measuring method

A measurement method and technology of tightening force, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of large dispersion of K value, many factors affecting K value, and difficult to handle properly. To achieve the effect of preventing bolt overload and ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

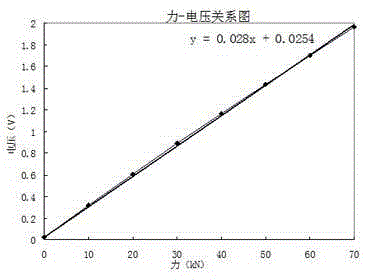

[0059] Step 1: Calibrate the pressure sensor, apply a force P of 0~180KN to the pressure sensor through the tensile test machine pressure fixture 0 , and record the voltage U of the force sensor 7 under different forces through the software of the tensile testing machine, the data of the force and voltage obtained are shown in Table 1, and the force-voltage curve is drawn as attached image 3As shown, according to the formula (1), the pressure-voltage relationship is obtained.

[0060] U=kF+b (1)

[0061] U——the voltage displayed by the pressure sensor, in V;

[0062] F——the force exerted by the tensile testing machine, in N;

[0063] k—coefficient, unit V / N;

[0064] b——the initial voltage displayed by the pressure sensor when the force is 0, in V.

[0065] The pressure-voltage relationship in this embodiment is: U=0.028 P0+0.0254.

[0066] Table 1 Pressure and sensor voltage detected during calibration of tensile testing machine

[0067]

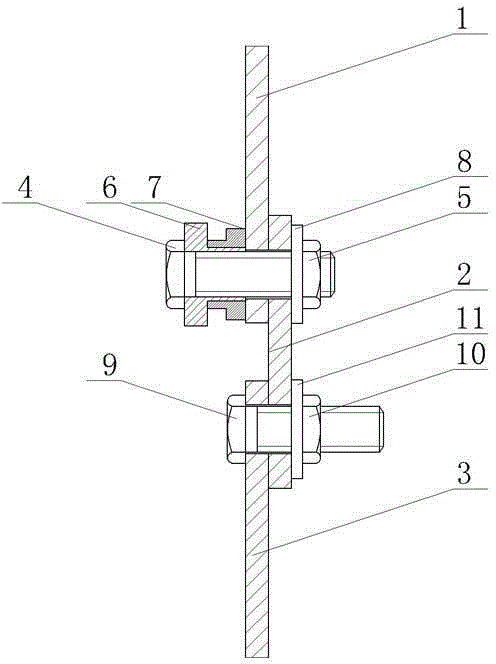

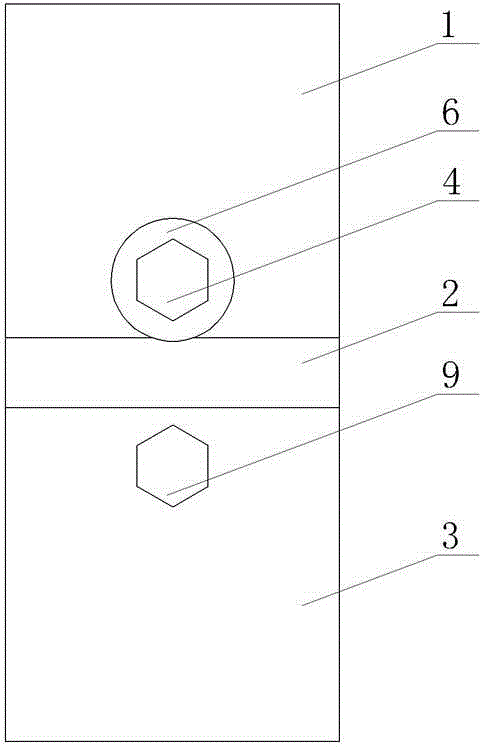

[0068] Step 2: As attached...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com