In-situ testing device for micro-mechanical properties of materials under tension-shear combined loading mode

A micromechanics, in-situ testing technology, applied in the direction of testing the ductility of materials, etc., can solve the lack of in-depth research on macro-scale and cross-scale in-situ micro/nano mechanical performance testing, and the inability to carry out in-depth combination of composite loads and materials. In order to achieve good development and application prospects, rich test content, and enrich the effect of in-situ micro-nano mechanical properties testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

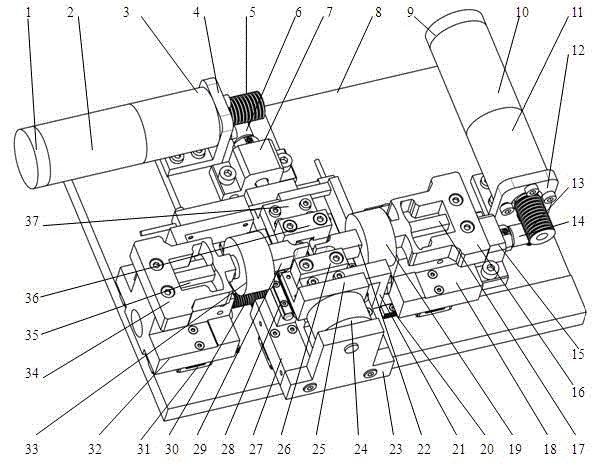

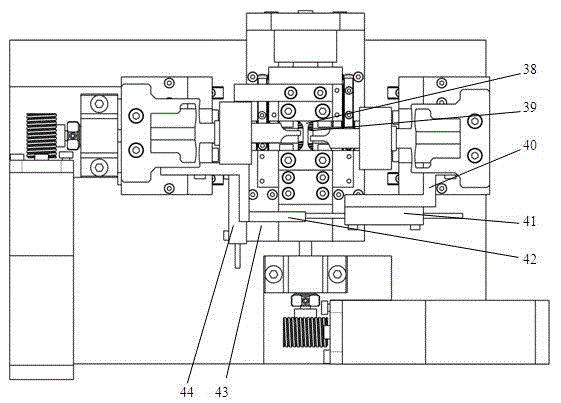

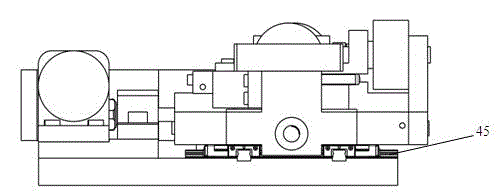

[0032] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0033] see Figure 1 to Figure 8 As shown, the in-situ test device for the micromechanical properties of materials under the tensile-shear composite loading mode of the present invention includes two parts: a tensile loading module and a shearing loading module, and the main structures of the tensile loading module and the shearing loading module are respectively It is composed of power components, transmission and execution components, signal detection and control components, and clamping support components;

[0034] The assembly relationship of the power components, transmission and execution components of the tensile loading module is: the hollow cup rotor DC motor I2 is connected with the planetary gear reducer I3, and then connected with the precision two-way ball screw I39 through the worm and worm gear pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com