Detection method for adhesion of gravure ink for plastic film

A detection method and technology for plastic films, which are applied in measuring devices, analytical materials, instruments, etc., can solve the problems of inability to detect plastic films, ink shedding, hidden dangers of food safety, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A gravure plastic film ink adhesion detection method, it is made up of following detection steps:

[0033] (1) Flatten the plastic film printed with the ink layer, and then paste the adhesive tape on the upper surface of the ink layer evenly, and roll it three times with a pressure roller with a constant load of 25N to obtain the sample;

[0034] (2) Place the sample obtained in step (1) on the platform between the upper and lower heating plates of the heat-sealing apparatus, the tightening pressure between the upper and lower heating plates is 2N, the heating temperature is 180°C, and the heating time is In 3.5 seconds, the surface area of the heat-sealing device heating and contacting the adhesive tape is 16mm*20mm;

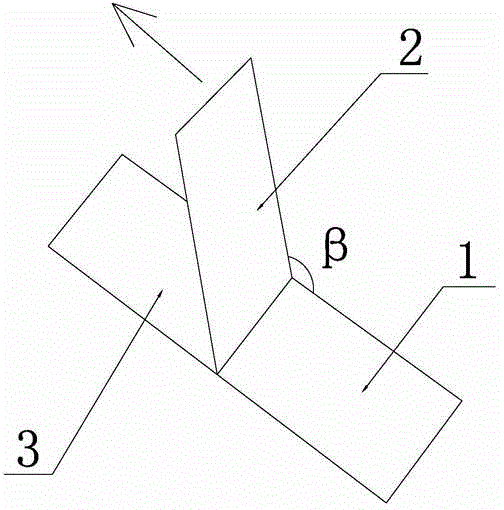

[0035] (3) Cool the sample obtained in step (2) to room temperature, and tear the adhesive tape in the same direction. The angle β formed by the adhesive tape and the plastic film is 140°. Observe whether the ink layer has Flaky peeling and whether th...

Embodiment 2

[0039] A gravure plastic film ink adhesion detection method, it is made up of following detection steps:

[0040] (1) Lay the plastic film printed with the ink layer flat, then paste the adhesive tape on the upper surface of the ink layer flatly, and use a pressure roller with a constant load of 20N to roll four times in the same direction to obtain a sample ;

[0041] (2) Place the sample obtained in step (1) on the platform between the upper and lower heating plates of the heat sealer, the tightening pressure between the upper and lower heating plates is 1N, the heating temperature is 220°C, and the heating time is In 2 seconds, the surface area of the heat-sealing device heating and contacting the adhesive tape is 15mm*22mm;

[0042] (3) Cool the sample obtained in step (2) to room temperature, and tear the adhesive tape in the same direction. The angle β formed by the adhesive tape and the plastic film is 130°. Observe whether the ink layer has Flaky peeling and whethe...

Embodiment 3

[0045] A gravure plastic film ink adhesion detection method, it is made up of following detection steps:

[0046] (1) Lay the plastic film printed with the ink layer flat, then paste the adhesive tape on the upper surface of the ink layer flatly, and use a pressure roller with a constant load of 22N to roll four times in the same direction to obtain a sample ;

[0047] (2) Place the sample obtained in step (1) on the platform between the upper and lower heating plates of the heat sealer, the tightening pressure between the upper and lower heating plates is 1.5N, the heating temperature is 200°C, and the heating time is For 2.5 seconds, the area of the plane where the heat sealer heats and contacts the adhesive tape is 16mm*21mm;

[0048] (3) Cool the sample obtained in step (2) to room temperature, and tear the adhesive tape in the same direction. The angle β formed by the adhesive tape and the plastic film is 135°. Observe whether the ink layer has Flaky peeling and whether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com