Sterilization method and application of hydrogen peroxide low-temperature plasma sterilizer

A technology of low-temperature plasma and hydrogen peroxide, which is applied in the field of medical system sterilization, can solve the problems of limited use and achieve the effect of enhancing penetration, improving sterilization effect, and good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

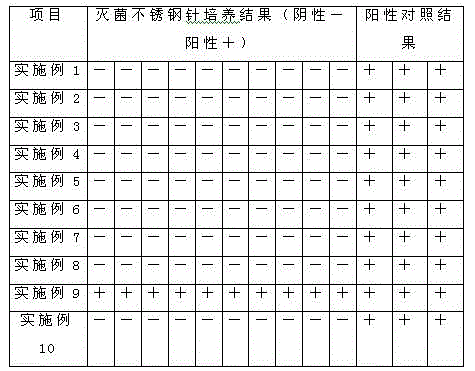

Examples

Embodiment 1

[0035] Put 10 stainless steel needles with a diameter of 0.3mm and a length of 40mm contaminated with spores of Bacillus stearothermophilus into the middle of ten stainless steel tube lumens with an inner diameter of 1mm and a length of 500mm, and put them into PS-100 low-temperature hydrogen peroxide plasma needles with qualified pressure holding. In the body sterilizer, set the parameters according to Table 1 for sterilization, and put the steel needles into the culture medium after sterilization.

[0036] Table 1 Control parameters

[0037] Evacuate the lower limit Hydrogen peroxide concentration after purification Vaporization chamber temperature Diffusion pressure Diffusion time Plasma power working time Sterilization cavity volume Sterilization chamber wall temperature 80pa 90% 73℃ 1450pa 8m0s 3m0s 125L 48℃

Embodiment 2

[0039] Put 10 stainless steel needles with a diameter of 0.3mm and a length of 40mm contaminated with spores of Bacillus stearothermophilus into the middle of ten stainless steel tube lumens with an inner diameter of 1mm and a length of 400mm, and put them into PS-100 type hydrogen peroxide low-temperature plasma with qualified pressure holding. In the body sterilizer, set the parameters according to Table 2 for sterilization, and put the steel needles into the culture medium after sterilization.

[0040] Table 2 Control parameters

[0041] Evacuate the lower limit Hydrogen peroxide concentration after purification Vaporization chamber temperature Diffusion pressure Diffusion time Plasma power working time Sterilization cavity volume Sterilization chamber wall temperature 80pa 90% 73℃ 1300Pa 8m0s 3m0s 125L 48℃

Embodiment 3

[0043] Put 10 stainless steel needles with a diameter of 0.3 mm and a length of 40 mm contaminated with spores of Bacillus stearothermophilus into the middle of 10 laparoscopic instruments, and put them into PS-100 type hydrogen peroxide low-temperature plasma sterilizers with qualified pressure holding. In the sterilizer, set the parameters according to Table 3 for sterilization, and put the steel needle into the culture medium after sterilization.

[0044] Table 3 Control parameters

[0045] Evacuate the lower limit Hydrogen peroxide concentration after purification Vaporization chamber temperature Diffusion pressure Diffusion time Plasma power working time Sterilization cavity volume Sterilization chamber wall temperature 80pa 90% 68℃ 1500Pa 8m0s 4m0s 125L 55℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com