Method for producing activated water by utilizing frequency resonance and implosion and high-frequency energy solution

A high-frequency energy and water activation technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve problems such as inconvenience and application limitations, achieve convenient use and improve solvency , the effect of inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

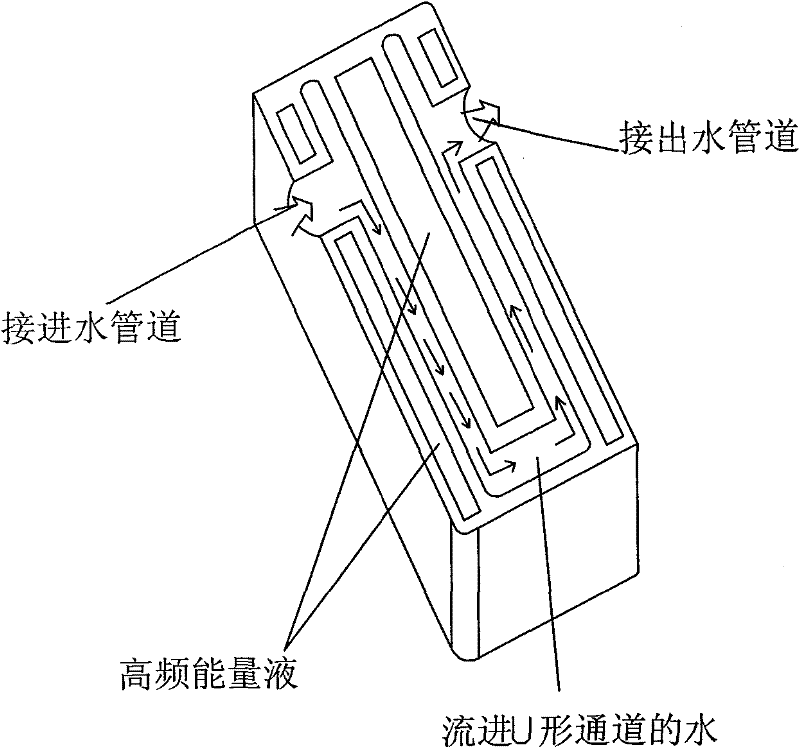

[0036] Preparation of energy liquid: 1) Mix natural magnetic powder, iron oxide, metasilicate and metal sodium, strontium, magnesium, zinc, and calcium according to the above ratio and melt at high temperature. 2) The high-temperature melted material is compounded by a special nano-vacuum mixer, and the compounded material and high-purity water are pressurized and microwave-extracted to form a mixed liquid. The frequency of the high-purity water itself and the frequency of the nano-composite liquid are superimposed to form a new high-frequency liquid magnetic field. 3) Enclose the high-frequency energy liquid in a magnetized solid steel container. The solid steel container has a built-in U-shaped groove, and the high-frequency energy liquid is filled around the U-shaped groove. The two sides of the solid steel container are respectively connected with steel pipes as water inlets and outlets. The steel pipes communicate with the U-shaped groove to form a running water system. ...

Embodiment 1

[0039] The application of embodiment 1 aspect vegetable cultivation

[0040] 1) Application in tomato production

[0041] 1. Materials and methods

[0042] 1.1 Test varieties

[0043] The tomato variety is "Zhongza 9".

[0044] 1.2 Test method

[0045] In order to prevent the lateral infiltration of water between treatments from affecting the test results, the test was carried out in a soilless cultivation method. The cultivation tank was made of bricks. The cultivation tank was 20 cm high, with an inner diameter of 60 cm and an outer diameter of 84 cm. The groove spacing was 70 cm and the groove length was 6.0 cm. m, 0.1 mm thick plastic film is laid in the tank, and the soilless cultivation substrate is composed of peat, slag and vermiculite. The physical and chemical properties of the mixed substrate in each cultivation tank are exactly the same, which can basically eliminate other factors difference due to influence.

[0046] The test set uses the technology to treat ...

Embodiment 2

[0091] Embodiment 2 is applied in industrial descaling

[0092] 1. Use object

[0093] The feed water of two horizontal fast-installed boilers is treated, respectively connected to the running water device of the present invention. One of the two boilers is 2 tons / hour (DZL2-13 type) and has been in operation for ten years; the other 4 tons / hour (DZL4-13 type) is a newly installed boiler. The two boilers are not used at the same time, one is running and the other is standby.

[0094] 2. Boiler status after using the running water device of the present invention

[0095] After the DZL2-13 type boiler has been using the running water device for 40 days, the boiler is cleaned for the first time. After the manhole and hand hole of the drum and the lower header are opened, it can be seen that there are many old scales falling off inside, mostly in the form of flakes, and There are a small number of arc-shaped long strips with triangular old scale, which is the old scale at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com