Dry-method sand manufacturing machine

A sand making machine and dry process technology, applied in grain processing and other directions, can solve the problems of large fineness modulus, poor grain shape, and incomplete gradation, and achieve good grain shape, optimized gradation, and water saving. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

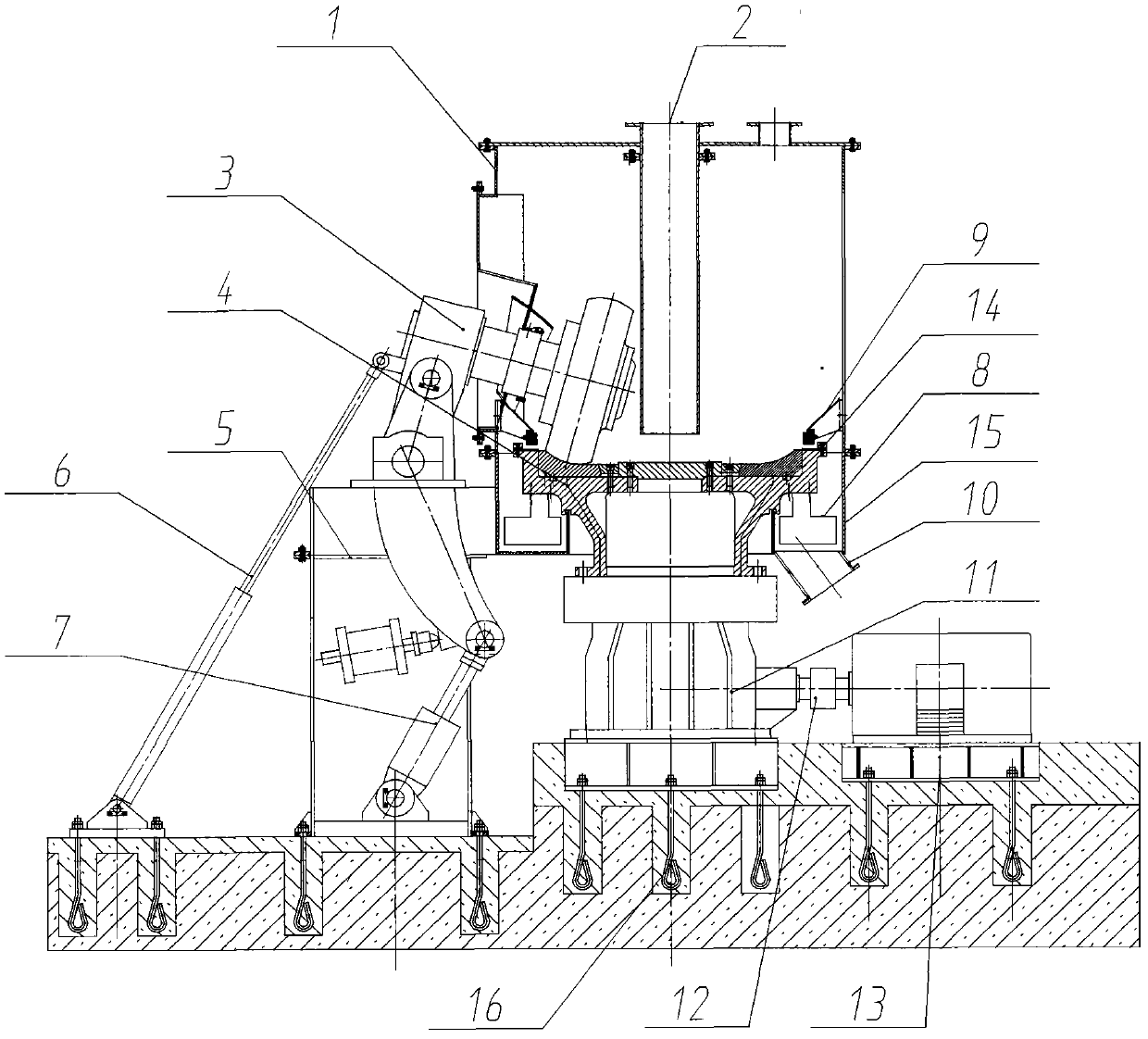

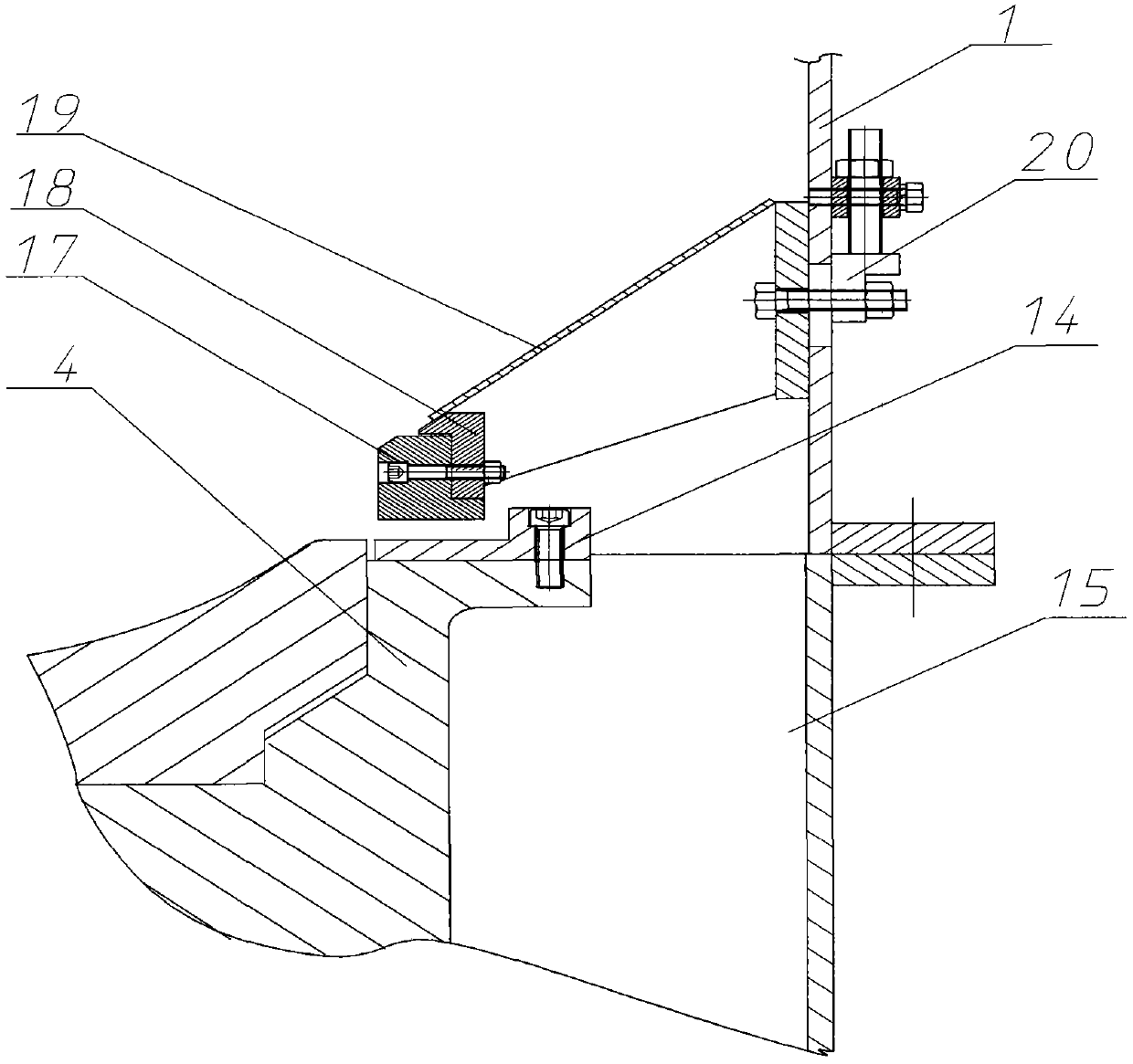

[0021] Such as figure 1 , figure 2 As shown, a dry sand making machine consists of an upper shell (1), a feed port (2), a rolling roller (3), a rolling plate (4), a support (5), an overhaul device (6), Working cylinder (7), scraper (8), inner screening device (9), discharge port (10), reducer (11), coupling (12), motor (13), moving ring (14) , the lower shell (15), and anchor bolts (16), the feed inlet (2) is set at the center of the upper part of the upper shell (1), and the discharge port (10) is on the bottom plate of the lower shell (15) , the rolling rollers (3) are evenly distributed on the rolling plate (4) in the upper casing (1), and the inner screening device (9) is fixed on the upper casing (1) through the adjustment device (20), and the supporting Seat (5) supports the weight of rolling roller (3), upper casing (1) and lower casing (15), and bearing (5) links to each other with foundation by anchor bolt (16).

[0022] A wear-resistant roller sleeve is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com