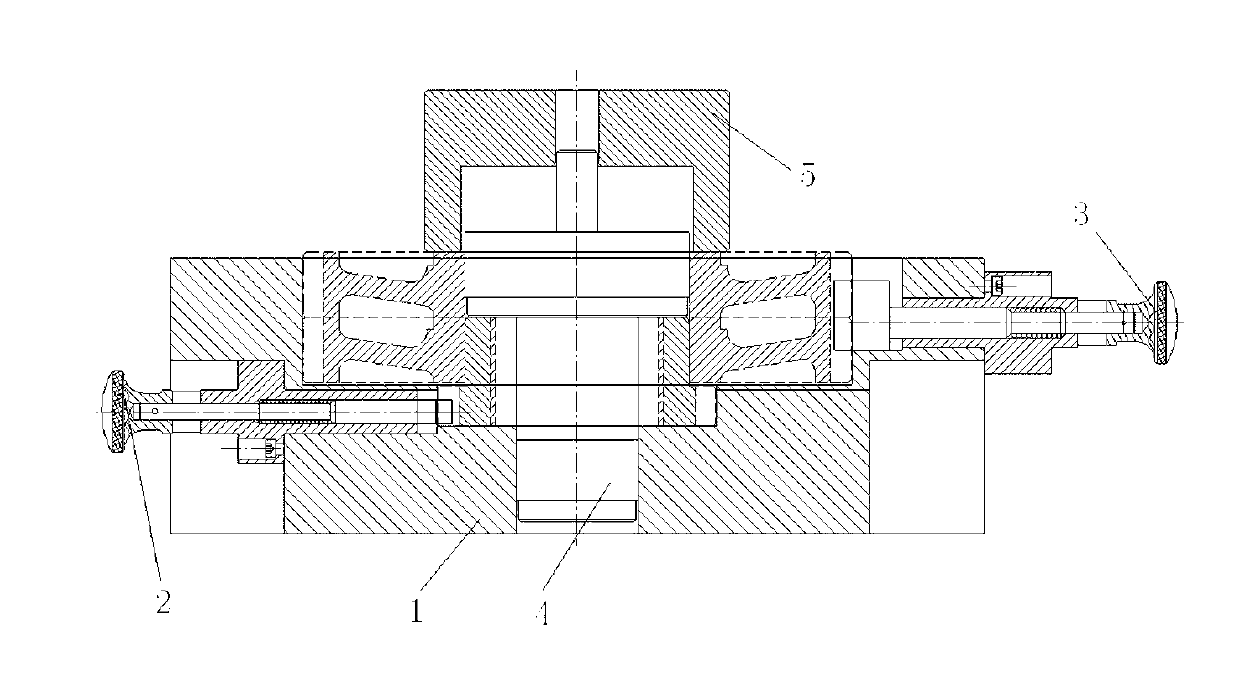

Gear press-mounting fixture

A press-fitting and fixture technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, metal processing, etc., can solve problems such as complex processing, and achieve the effects of low investment cost, reduced processing difficulty, and reasonable and reliable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The gear pressing fixture includes a base 1 fixed on the machine tool. The lower part of the outer circumference of the base 1 is provided with an elastic telescopic positioning rod I2 which is symmetrical to the axis of the base 1. The upper part of the outer circumference of the base 1 is provided with a Symmetrical elastic telescopic positioning rod II3, the axis of the base 1 is provided with a guide mandrel 4, the guide mandrel 4 is pierced with a pressure head 5 located above the base 1, the front end of the elastic telescopic positioning rod I2 is a conical round head, The front end of the elastic telescopic positioning rod II3 is a duckbill-shaped structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com