Preparation method of polypropylene short fibers without peculiar smells

A polypropylene staple fiber, odor-free technology, applied in fiber treatment, conjugated synthetic polymer artificial filament, filament/thread forming, etc., can solve the problem of non-woven fabrics emitting odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

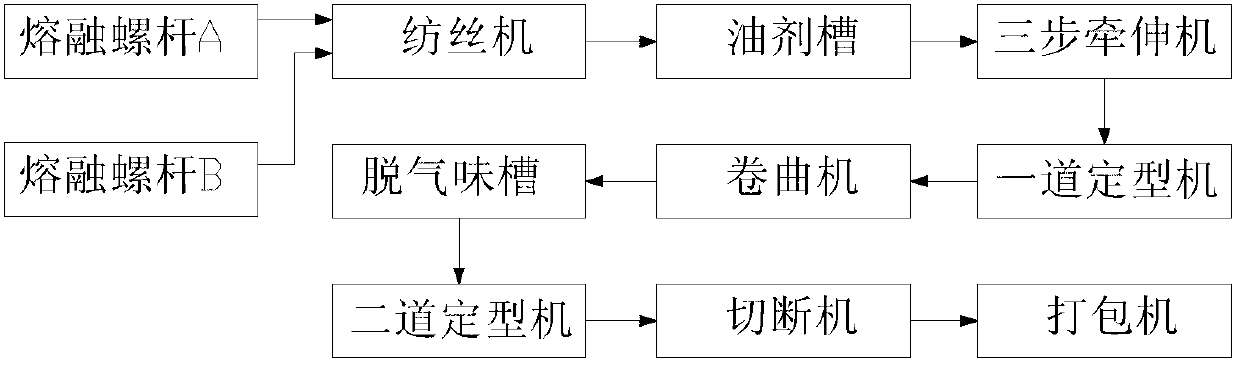

[0016] The present invention provides a kind of preparation method of polypropylene staple fiber without peculiar smell, flow process is as follows figure 1 shown, including the following:

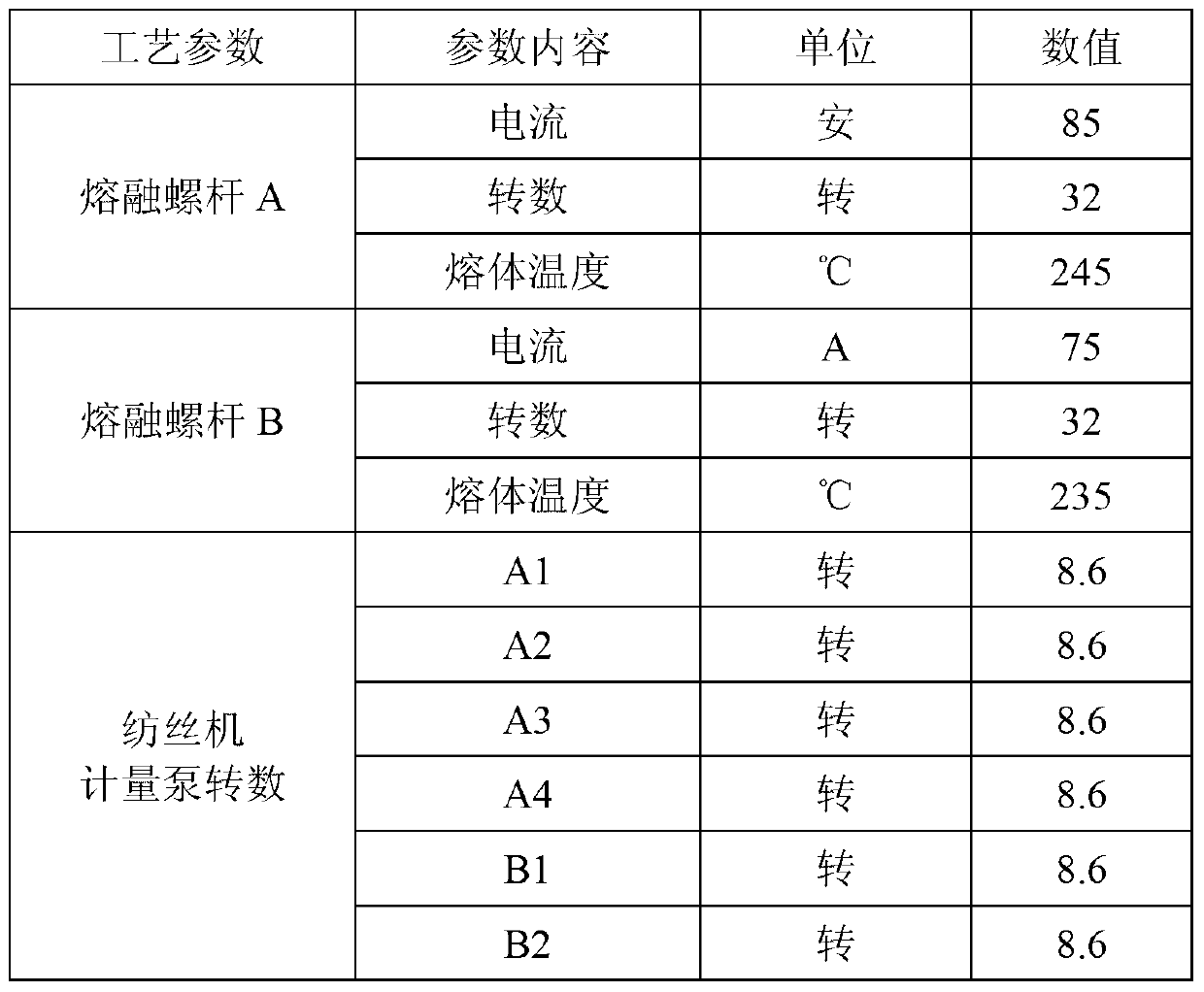

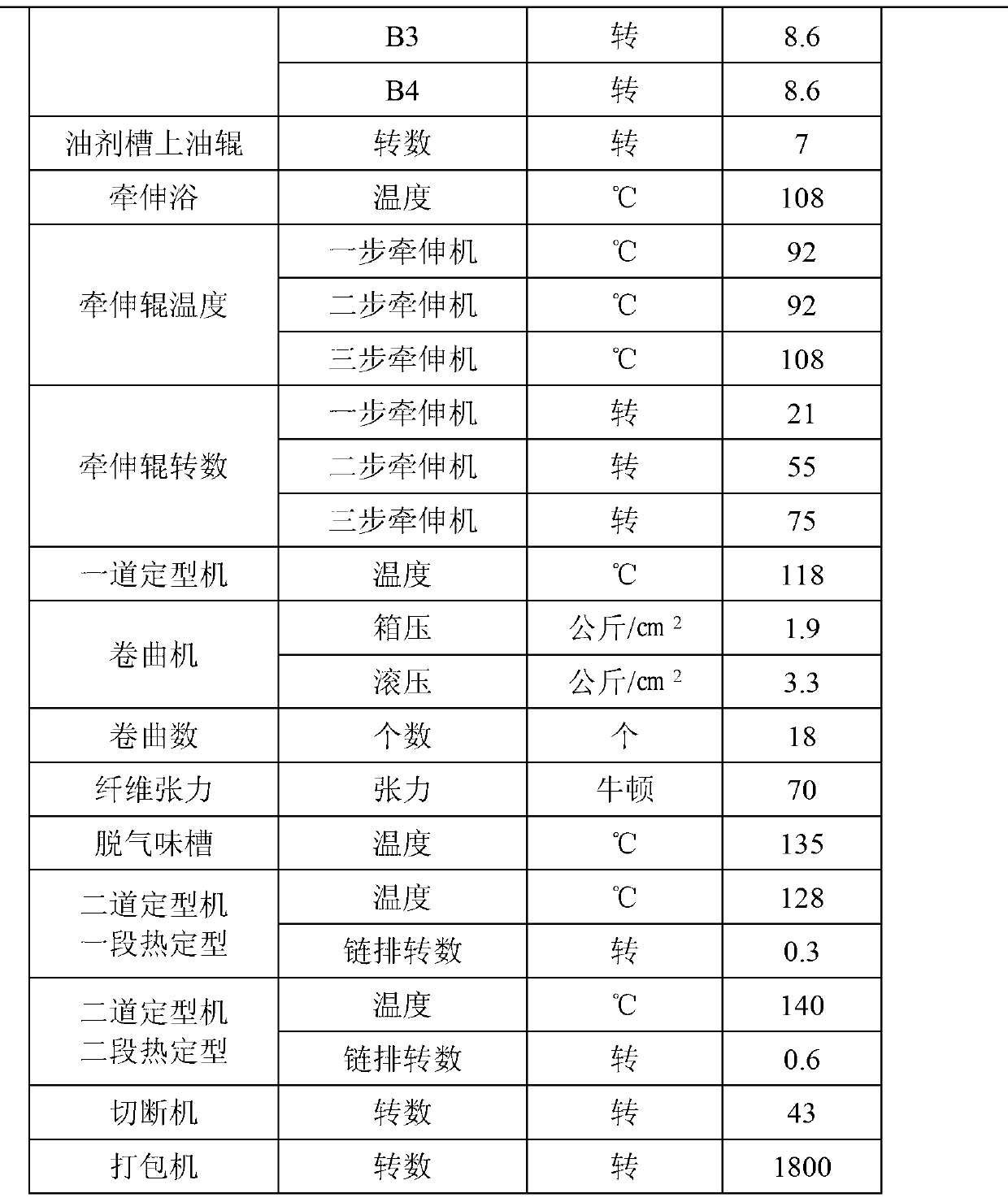

[0017] Add polypropylene chips with a polymelt index of 32g / 10min into the melting screw A as the skin layer. The temperature of each zone of the screw A is 245-250°C in zone 1, preferably 247°C, 247-253°C in zone 2, preferably 250°C, and 250°C in zone 3. ~255°C, preferably 252°C, zone 4 253~258°C, preferably 255°C, zone 5 258~275°C, preferably 265°C, zone 6 258~275°C, preferably 265°C, zone 7 258~275°C, preferably 265°C °C; the melt temperature of the melting screw A is preferably 245 °C to 275 °C, more preferably 265 °C, the number of revolutions is preferably 32 to 45 revolutions, more preferably 39 revolutions, and the current is preferably 85 to 130 amps, more preferably 98 amps;

[0018] Add polypropylene chips with a melt index of 28g / 10min into the melting screw B as the core lay...

Embodiment 1

[0026] Add polypropylene slices with a melt index of 32g / 10min to melting screw A as the skin layer, and add polypropylene slices with a melt index of 28g / 10min to melt screw B as the core layer, and the skin layer and core layer are based on a mass percentage of 40:60 Add it to the metering pump of the spinning machine. After the fiber is formed, coat the fiber surface with the odorless oil agent F-2169 oil, and then pass through the oil tank oiling stick, three-step drafting machine, a sizing machine, a crimping machine, and a stripping machine. The fiber bundles are obtained after the smell tank and the second setting machine, and the above fiber bundles are cut by a cutting machine to obtain polypropylene staple fibers without peculiar smell; the temperature of each zone of the screw A is 245°C in the 1st zone, 247°C in the 2nd zone, 250°C in the 3rd zone, and 4 Zone 253°C, zone 5 258°C, zone 6 258°C, zone 7 258°C, the temperature of each zone of screw B is 235°C in zone 1,...

Embodiment 2

[0033] Add polypropylene slices with a melt index of 32g / 10min to melting screw A as the skin layer, and add polypropylene slices with a melt index of 28g / 10min to melt screw B as the core layer, and the skin layer and core layer are 50:50 by mass Add it to the metering pump of the spinning machine. After the fiber is formed, coat the fiber surface with the odorless oil agent F-2169 oil, and then pass through the oil tank oiling stick, three-step drafting machine, a sizing machine, a crimping machine, and a stripping machine. The fiber bundles are obtained after the odor tank and the second setting machine, and the above fiber bundles are cut by a cutting machine to obtain polypropylene staple fibers without peculiar smell; the temperature of each zone of the screw A is 247°C in the 1st zone, 250°C in the 2nd zone, 252°C in the 3rd zone, and 4 zone 255°C, zone 5 265°C, zone 6 265°C, zone 7 265°C; the temperature of each zone of screw B is 238°C in zone 1, zone 2 240°C, zone 3 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com