A WSN float liquid level detection device and method for environmental protection

A liquid level detection and liquid level technology, applied in the direction of buoy liquid level indicator, etc., can solve the problems of affecting accuracy, large temperature change, unusable in explosion-proof occasions, etc., and achieve the effect of accurate transmission and flexible installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

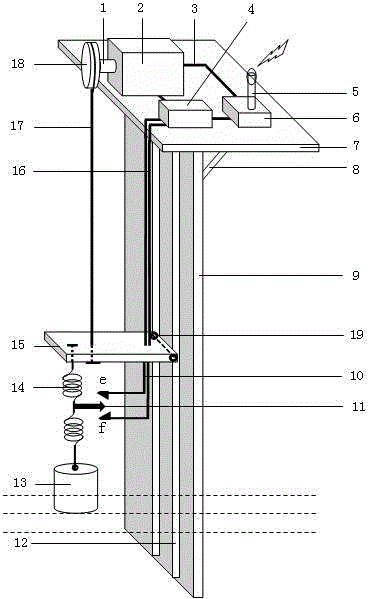

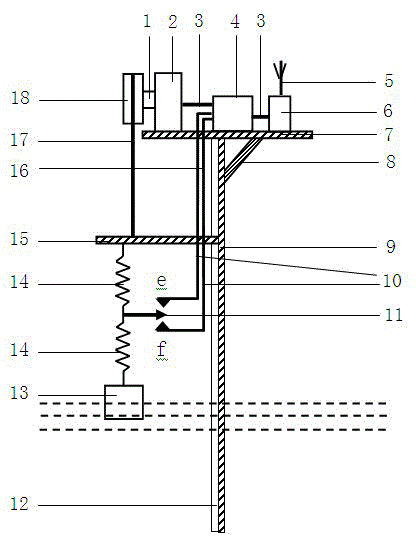

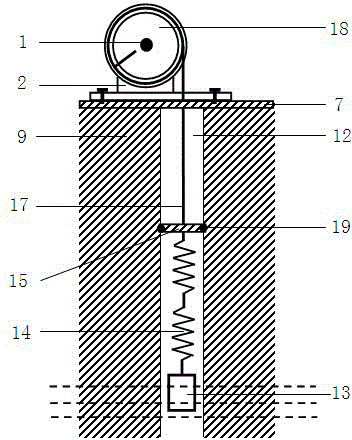

[0020] see Figure 1~4 , the supporting part of the present invention is made up of horizontal bracket bottom plate 7 and vertical slide rail bracket 9, and slide rail bracket 9 is positioned at the bottom of bracket bottom plate 7, and the upper end of slide rail bracket 9 is fixedly connected on the bottom surface of bracket bottom plate 7, on slide rail The upper end of the support 9 and the support base plate 7 are fixedly connected with a tripod 8 to strengthen the stability of the supporting part. Stepper motor 2, control system device 4 and WSN remote communication module 6 are fixedly placed on the top surface of support base plate 7, stepper motor 2 is mechanically connected to winding guide wheel 18 by stepper motor bearing 1, and stepper motor 2 also passes through The control signal line 3 is electrically connected to the control system device 4 , the control system device 4 is electrically connected to the WSN remote communication module 6 through the control sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com