A multi-axis bolt tightening test bench

A technology for test benches and shaft bolts, which is applied in the field of bolt assembly, can solve problems such as shortage, insufficient control precision of pre-tightening force, difficulty in controlling and ensuring assembly quality, etc., and achieves convenient and simple workpiece clamping, convenient movement, and increased flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

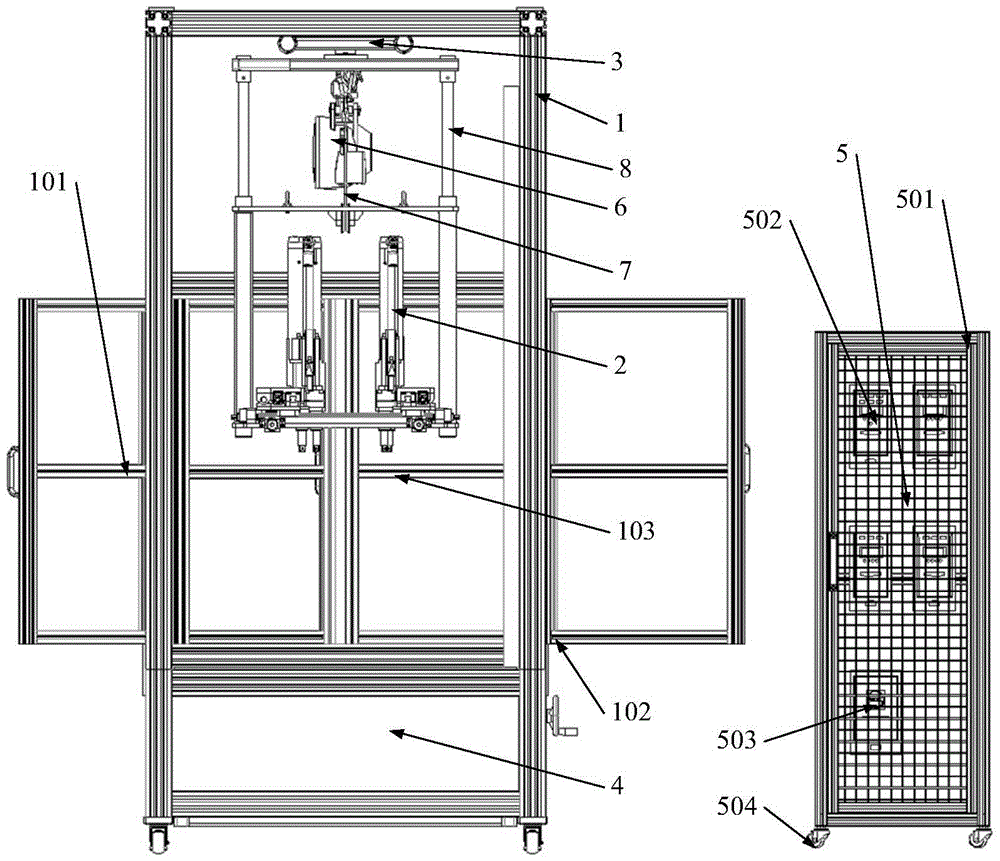

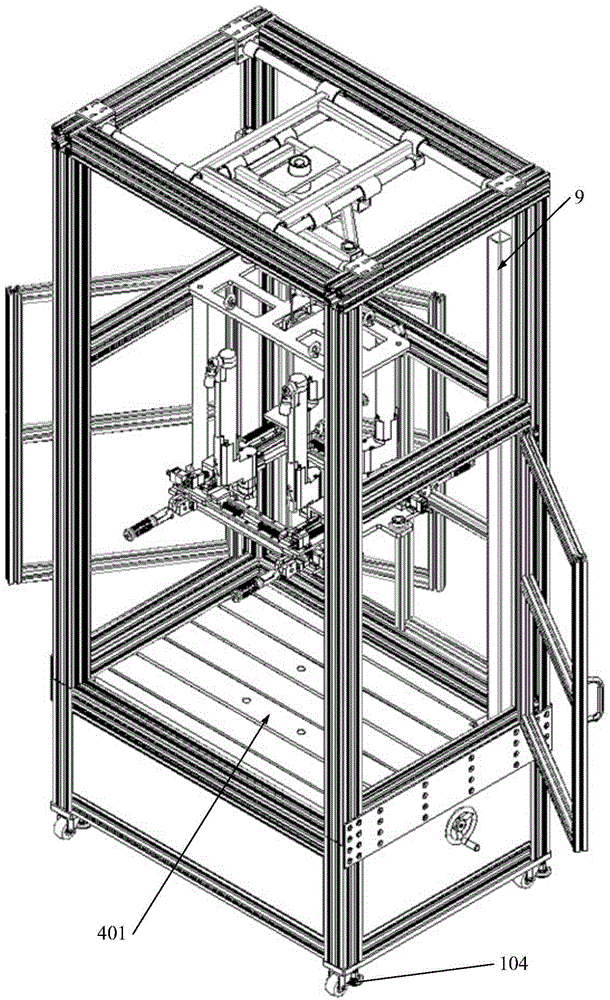

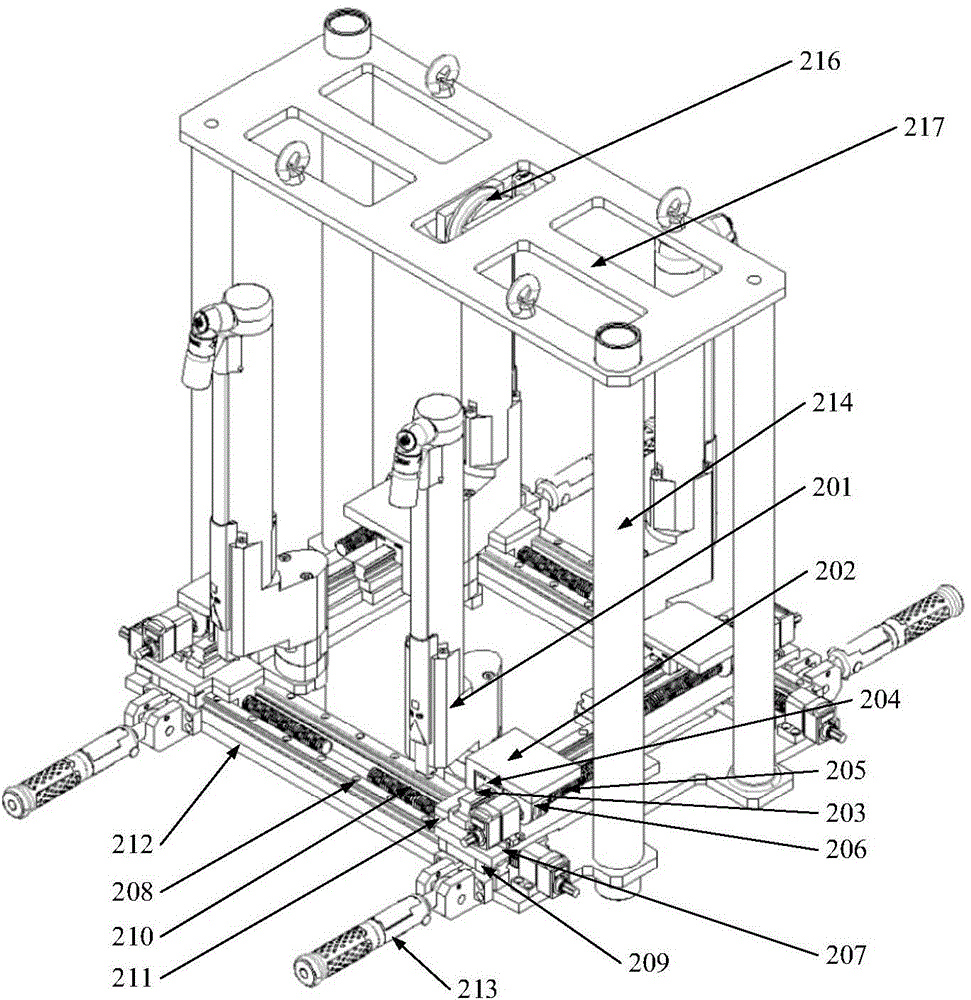

[0031] see figure 1 , the present invention includes a body frame 1, and a tightening mechanism 2, a top beam mechanism 3 and a workbench lifting module 4 respectively installed on the body frame 1, the tightening mechanism 2 is also connected with a control module 5; the body frame 1 is made of aluminum profile beams, Including the left protective door 101, the right protective door 102 installed on the side of the aluminum profile beam of the body frame 1 through hinges, and the rear protective door 103 arranged on the back of the body frame 1; The tightening mechanism 2 is installed on the diamond-shaped beam frame 301 of the top beam mechanism 3 through the steel wire rope 7 and the spring balancer 6. The tightening mechanism 2 includes a tightening platform top beam 217 and a tightening platform base 212; the diamond-shaped beam frame 301 is provided with two top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com