Device for low-temperature stretching test of metal material

A tensile test, metal material technology, used in measuring devices, analyzing materials, using stable tension/pressure to test the strength of materials, etc., can solve the problems of accurate and simple measurement methods, difficult to accurately control temperature, etc. The effect of temperature uniformity, good thermal insulation performance and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing,

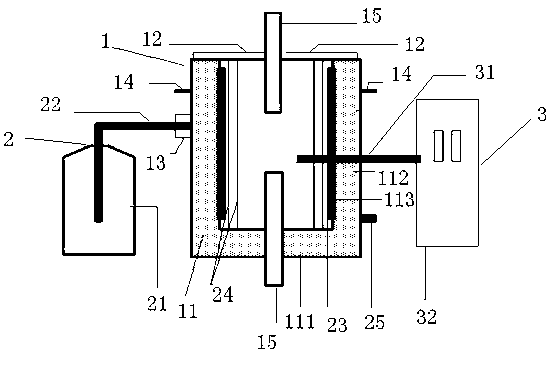

[0019] A device for low-temperature tensile testing of metal materials according to the present invention, comprising a box device 1 for placing samples, a liquid nitrogen device system 2 for cooling, and a temperature control system 3 for controlling the test temperature, the box device 1 includes a box body 11 and a box cover 12 arranged on the upper end of the box body 11, and a sealing material for heat preservation is provided between the box body and the box cover. The box body includes an inner layer 111 and an outer layer 113, and an insulating layer 112 arranged between the inner layer and the outer layer; both the inner layer and the outer layer are made of stainless steel. The insulation layer is polyurethane insulation board. Handles 14 are provided on both sides of the upper part of the casing. A fixed connection shaft 15 for adding samples is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com