Method for positioning discharging fault in gas insulated switchgear (GIS)

A discharge and fault technology, applied in the field of detection, can solve the problems of insulation breakdown, threats to the safety of power production, and high working field strength of insulation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

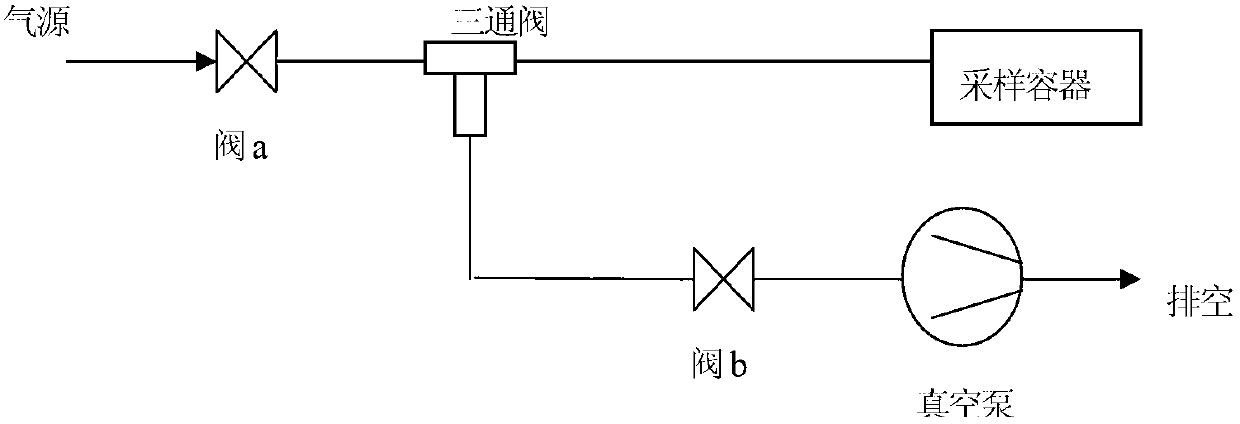

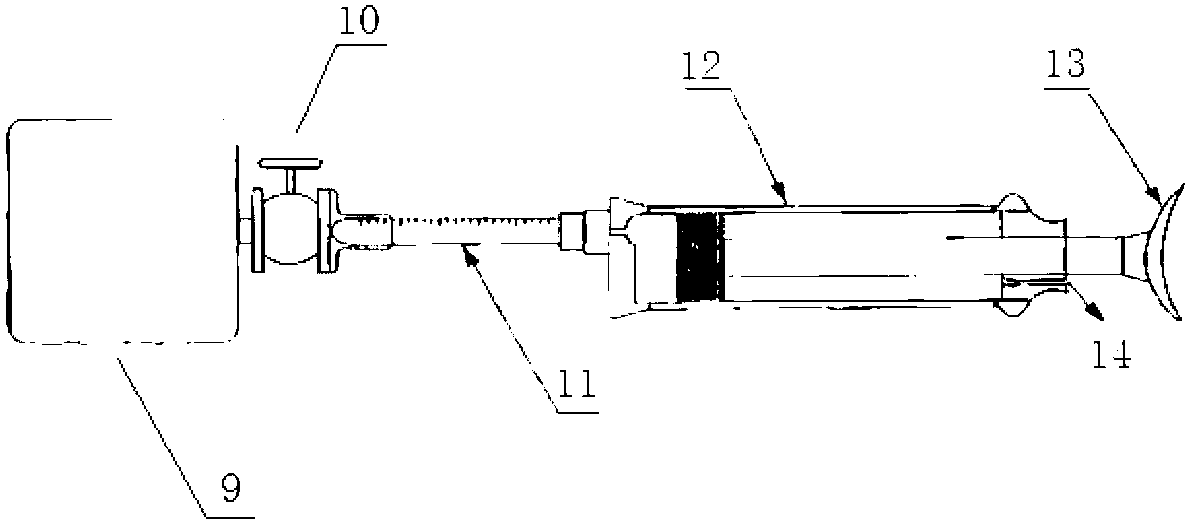

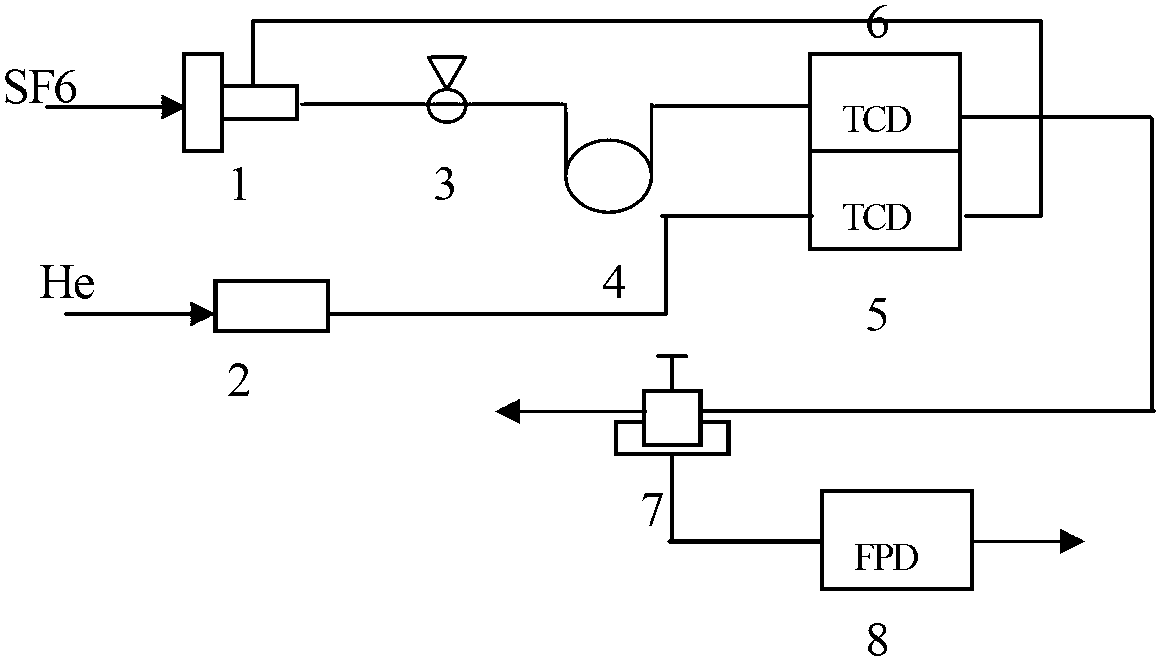

[0057] 1. Gas collection: the sampling device collects the gas sample from the gas source into the sampling container, which is composed of a vacuum pump and a connection system. The sampling container can be selected from 0.5L-1.0L PTFE-coated stainless steel with a three-way device Steel cylinder or 1.0L sampling bag; connecting pipelines are connected by polytetrafluoroethylene tubes, and there should be matching joints for sampling on electrical equipment; check the sampling device and connecting pipelines before sampling to keep them clean and dry; the connecting pipelines are sealed good.

[0058] Specific sampling method:

[0059] a) press figure 1 Connect the sampling container to the gas source and vacuum pump.

[0060] b) Close valve a, open valve b, rotate the three-way valve, connect the sampling container to the vacuum pump, start the vacuum pump, and vacuum the sampling system for 2-5 minutes until the system pressure drops to -0.1MPa.

[0061] c) Close valve ...

Embodiment 2

[0088] A 500kV GIS used other methods to detect and found that there were SO 2 +SOF 2 Components, H was not detected in all cells 2 S and HF components. Routine follow-up detection found that the components had an increasing trend, as shown in Table 2.

[0089] Table 2 Test records of SF6 decomposition products in GIS of a certain station

[0090]

[0091]

[0092] Preliminary analysis shows that the decomposition of No. 2 gas chamber has increased significantly, and it is judged that there is a continuous partial discharge inside, and it is recommended to disassemble and repair to eliminate defects.

[0093]Due to the huge impact of the power outage, the method of the present invention is used for detection and comparison to analyze whether there is discharge.

[0094] Adopt on-the-spot detection tube sampling analysis of the present invention and send laboratory chromatographic detection, table 3 is the on-site use decomposition product detection tube test result, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com