A thermal simulation analysis method for lithium-ion battery with multi-layer sheet structure

A lithium-ion battery, multi-layer flake technology, used in electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that physical properties and thermal characteristics cannot be fully reflected, effectiveness needs to be improved, and battery research and development cannot be matched. The designer provides and other problems to achieve the effect of convenient comparison and screening, quick and easy calculation, and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

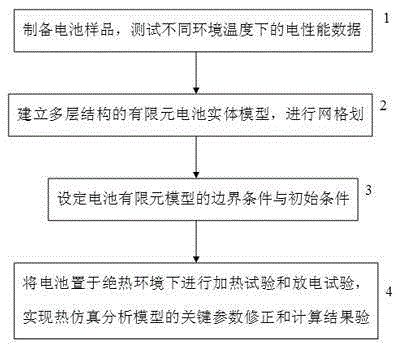

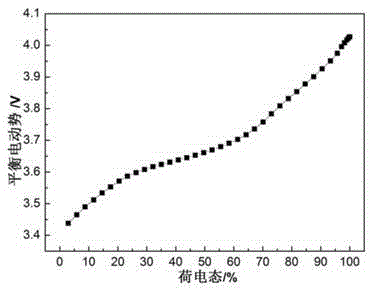

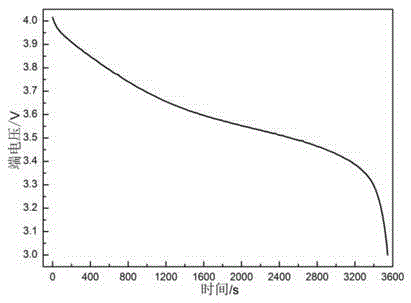

[0049] Based on the electrical performance data such as battery equilibrium electromotive force and discharge process open circuit voltage measured under controlled ambient temperature, use parametric design language to establish a battery entity model with detailed structure down to the battery separator, active material layer and metal foil layer and divide it into finite elements Grid, according to the electrical performance measurement results, the key model parameter of the battery heat generation rate that can change with time can be accurately given, and other corresponding boundary conditions and initial conditions are added in combination with the specific operating conditions of the battery for transient calculations. The calculation results can accurately analyze the transient temperature distribution of any fine structure inside the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com