A kind of secondary lithium-air battery cathode catalyst and its application

A cathode catalyst, lithium-air battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as not fully utilizing the advantages of transition metal catalytic materials, poor conductivity of transition metal oxides, and inability to exert electrocatalytic performance. , to achieve the effect of excellent catalytic efficiency, reduced production cost and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

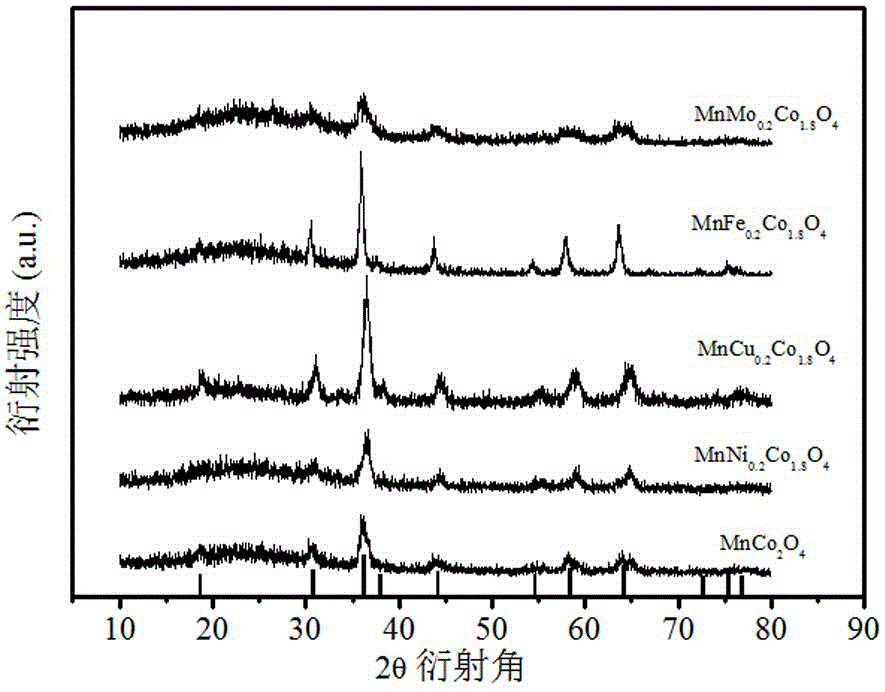

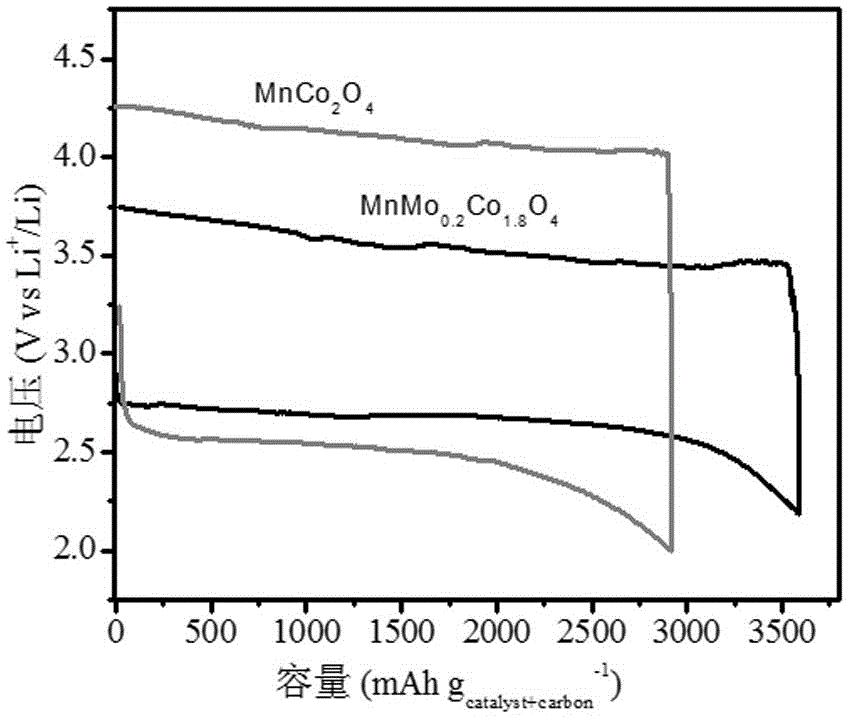

[0043] Embodiment 1: Co-precipitation method prepares MnFe 0.2 co 1.8 o 4

[0044] Weigh 0.0012molC according to the stoichiometric ratio 4 h 6 MnO 4 4H 2 O,0.00024molFe(NO 3 ) 3 9H 2 O,0.00216molCo(NO 3 ) 2 ·6H 2 O was dissolved in 500ml of deionized water, then 0.72mol of urea was added, sealed, magnetically stirred and kept at 75°C for 24h, after the black precipitate was obtained, it was centrifuged and washed several times with deionized water, then placed in an oven, kept at 75°C and all The water evaporates. Finally, the black precipitate is calcined at 600°C for 3 hours to obtain a black powder that is MnFe 0.2 co 1.8 o 4 .

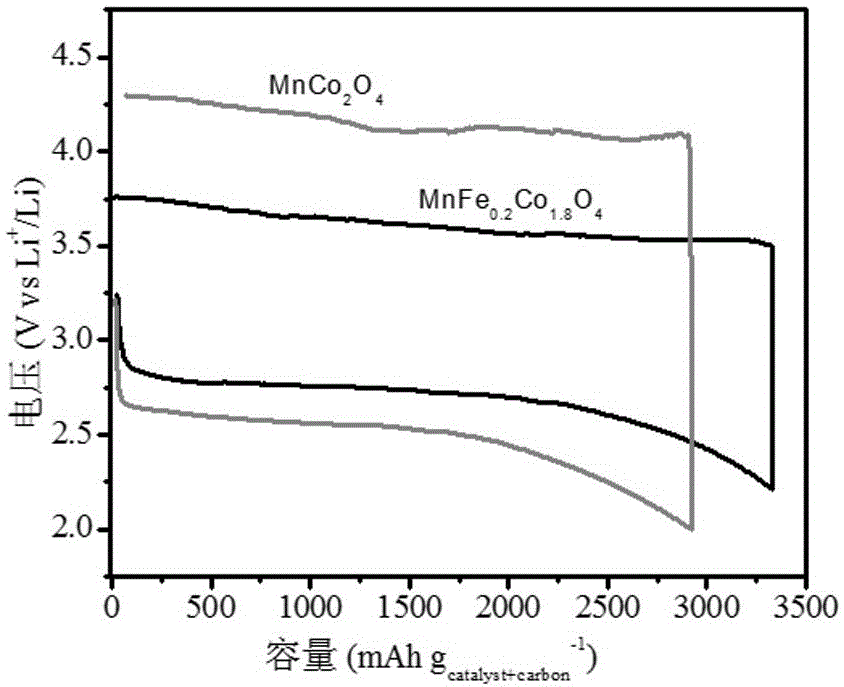

[0045] Prepare a button battery and test it, first discharge it to 2.0V at 30mA / g, then charge it to 4.2V, the released capacity is expressed as MnFe 0.2 co 1.8 o 4 Calculated with the total mass of acetylene black, it reaches 3335mAhg -1 ; And the charging potential is 3.53~3.75V, and the discharging potential is 2.00~2.84V. ...

Embodiment 2

[0047] Embodiment 2: Co-precipitation method prepares Mn 0.8 Fe 0.2 co 2 o 4

[0048] Weigh 0.00096molC according to the stoichiometric ratio 4 h 6 MnO 4 4H 2 O,0.00024molFe(NO 3 ) 3 9H 2 O,0.0024molCo(NO 3 ) 2 ·6H 2 O was dissolved in 500ml of deionized water, then 0.72mol of urea was added, sealed, magnetically stirred and kept at 75°C for 24h, after the black precipitate was obtained, it was centrifuged and washed several times with deionized water, then placed in an oven, kept at 75°C and all The water evaporates. Finally, the black precipitate is calcined at 550°C for 3 hours to obtain a black powder which is Mn 0.8 Fe 0.2 co 2 o 4 .

Embodiment 3

[0049] Embodiment 3: Co-precipitation method prepares MnCu 0.2 co 1.8 o 4

[0050] Weigh 0.0012molC according to the stoichiometric ratio 4 h 6 MnO 4 4H 2 O,0.00024molCu(NO 3 ) 2 ·3H 2 O,0.00216molCo(NO 3 ) 2 ·6H 2 O was dissolved in 500ml of deionized water, then 0.72mol of urea was added, sealed, magnetically stirred and kept at 75°C for 24h, after the black precipitate was obtained, it was centrifuged and washed several times with deionized water, then placed in an oven, kept at 75°C and all The water evaporates. Finally, the black precipitate is roasted at 600°C for 5 hours to obtain a black powder that is MnCu 0.2 co 1.8 o 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com