Mechanical synchronous hybrid relay and hybrid switch operating method

A hybrid relay and mechanical synchronization technology, applied in relays, electronic switches, circuits, etc., can solve the problems of limited synchronization effect, unsolved semiconductor switch off synchronization, input voltage fluctuations, etc., to achieve a wide range of working voltage and eliminate soft features The effect of failure, shortening the transition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

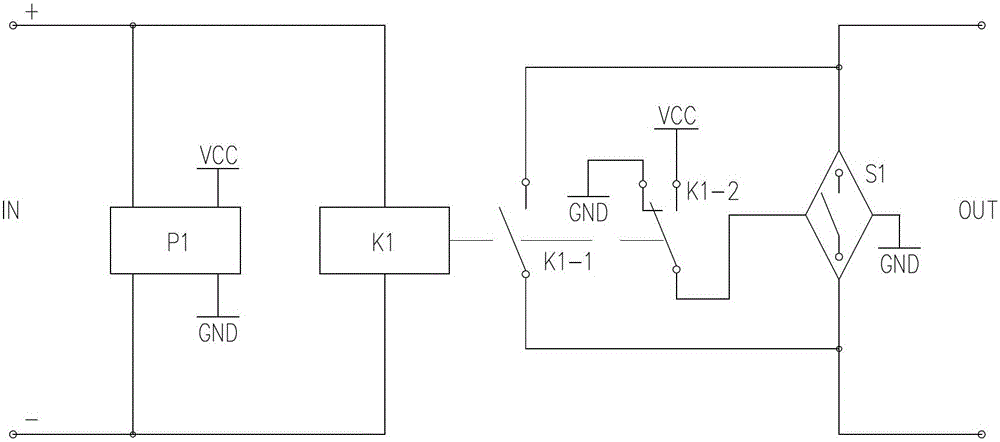

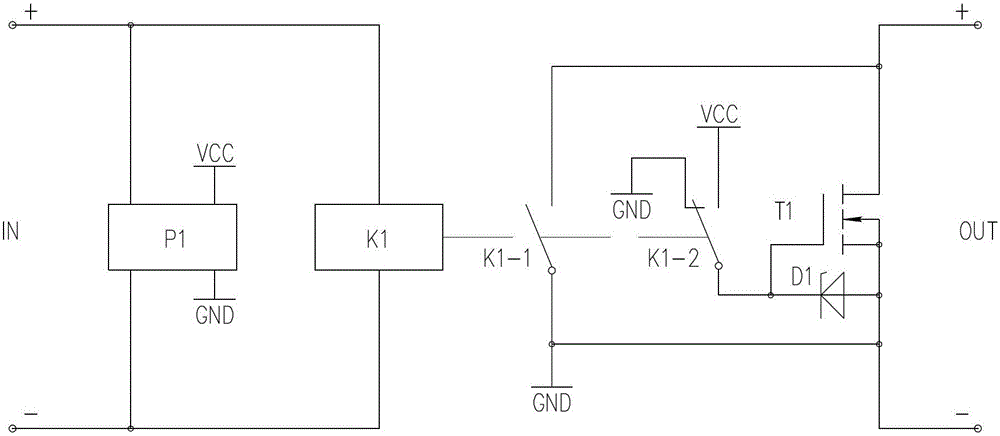

[0029] This embodiment is a DC type mechanical synchronous hybrid relay, the schematic diagram of the DC type mechanical synchronous hybrid relay is as follows figure 2As shown, the working timing diagram of the mechanical synchronous hybrid relay is as follows Figure 7 shown.

[0030] A DC type mechanical synchronous hybrid relay is mainly composed of an electromechanical relay and a solid state relay. The above-mentioned electromechanical relay includes a relay coil K1 and a mechanical contact switch. The above-mentioned solid state relay includes a driving power source P1 and a semiconductor switch S1. Wherein, the semiconductor switch S1 includes a field effect transistor T1, and a Zener diode D1 connected in parallel with the gate and source of the field effect transistor T1. The input terminal of the driving power P1 and the relay coil K1 are connected to the input terminal of the hybrid relay, and the driving power P1 provides energy support for the conduction of t...

Embodiment 2

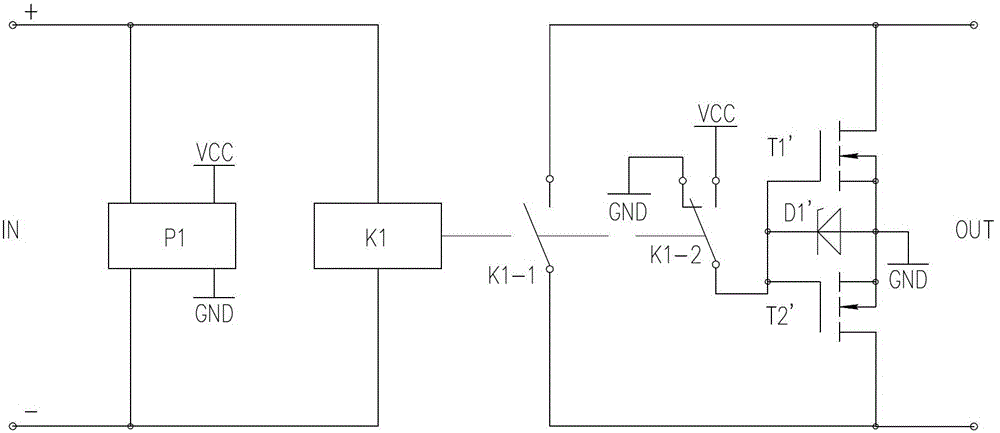

[0036] This embodiment is an AC-DC type mechanical synchronous hybrid relay, and the schematic diagram of the DC type mechanical synchronous hybrid relay is as follows image 3 As shown, the working timing diagram of the mechanical synchronous hybrid relay is as follows Figure 7 shown.

[0037] Embodiment 2 is based on Embodiment 1, and a reverse conduction semiconductor switch field effect transistor T2' is added on the basis of the field effect transistor T1' of the forward conduction semiconductor switch S1, so that S1 becomes a bidirectional semiconductor switch. Controls the switching on or off of AC or DC current. The source of the field effect transistor T1', the source of the field effect transistor T2' and the cathode of the Zener diode D1' are connected. The gate of the field effect transistor T1', the gate of the field effect transistor T2' are connected to the anode of the Zener diode D1'.

[0038] The control mode of embodiment 2 is the same as that of embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com