Processing method for broken black tea

A processing method and technology for broken black tea, which are applied in the field of processing black broken tea, can solve the problems of high production cost and loss of nutrients in black broken tea, and achieve the effects of low cost, reduced loss of nutrients and enhanced aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

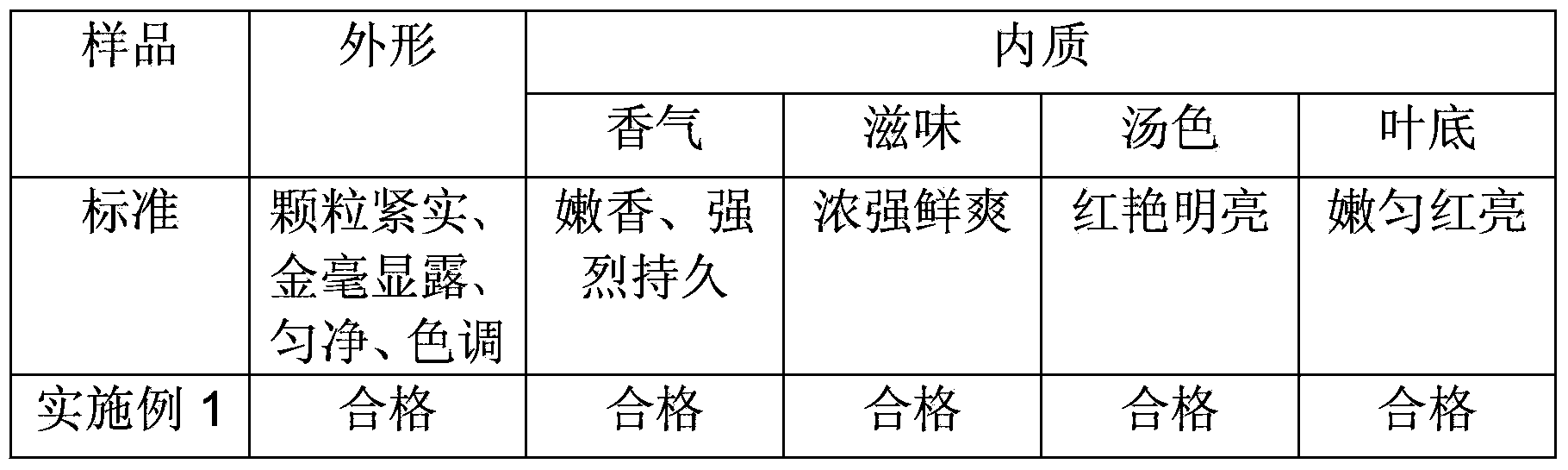

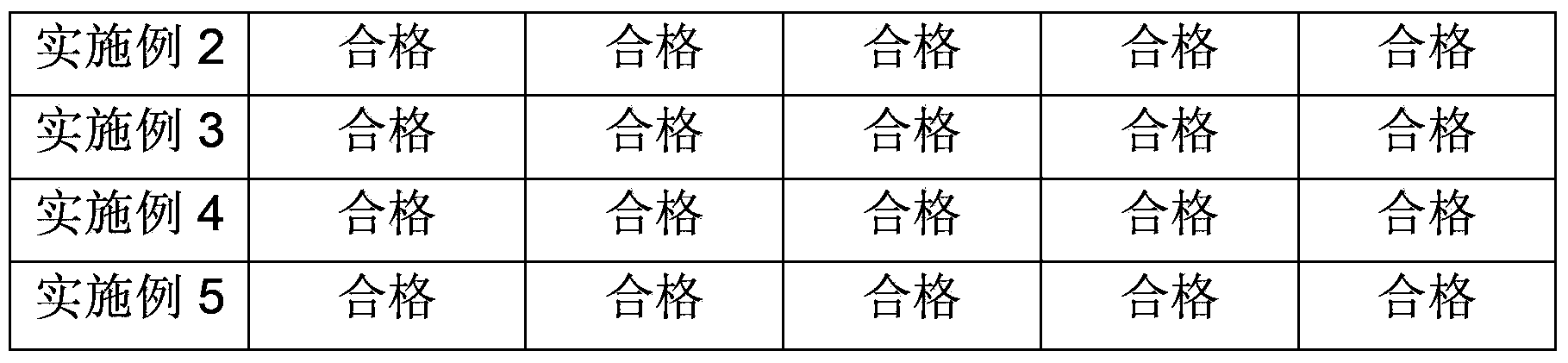

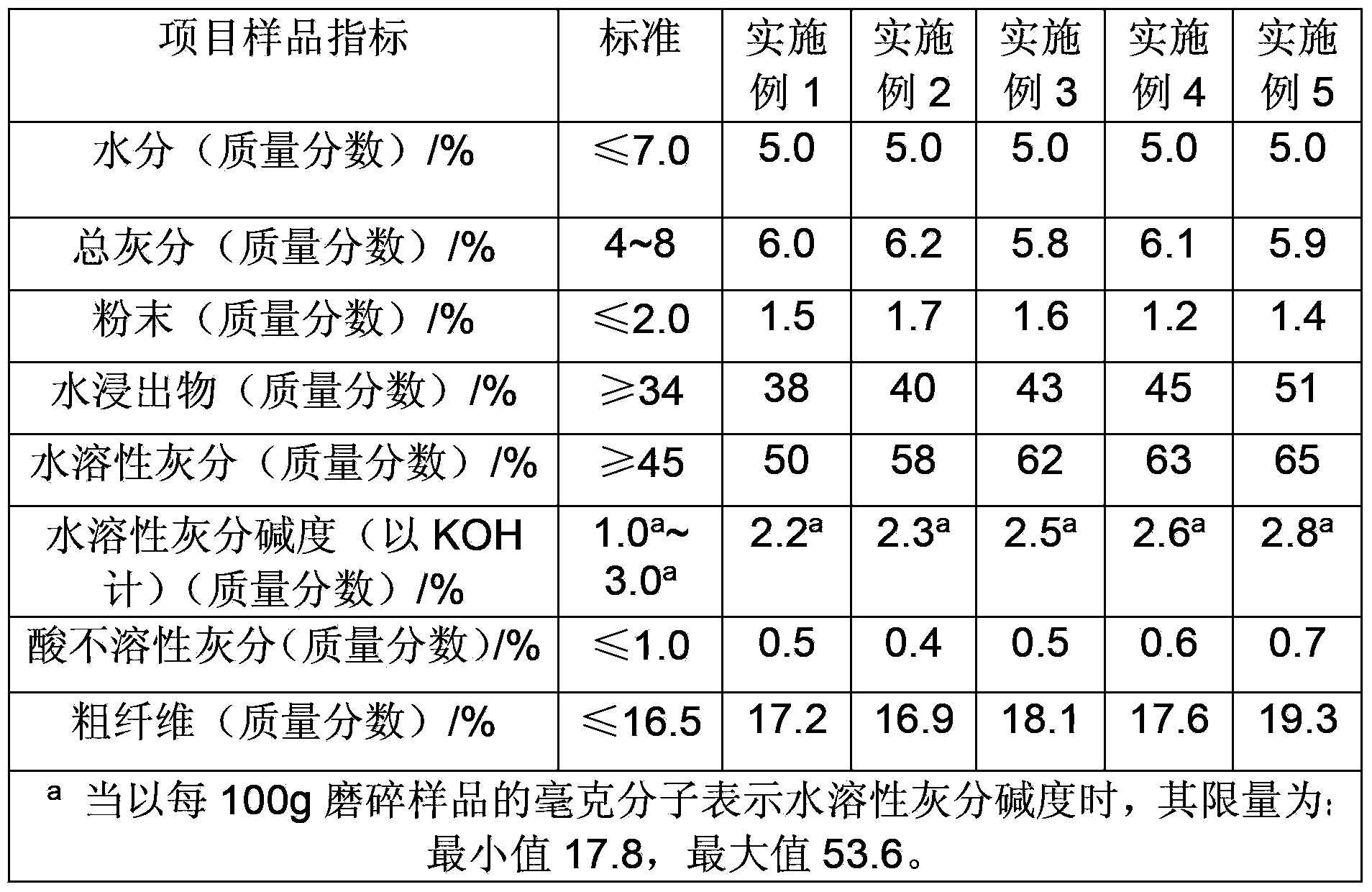

Examples

Embodiment 1

[0052] (1) Selection and picking of fresh leaves

[0053] Select the fresh leaves of Qinglong big-leaf tea with one bud, one leaf and two leaves as the main fresh leaves, and single leaves with the same tenderness, as raw materials, and pick the fresh leaves of standard grade 2;

[0054] (2) Lay it flat on the ground for natural withering under indoor weak light conditions

[0055] Spread the picked fresh leaves on the ground with a leaf thickness of 15cm, and control the moisture content of the withered leaves at 68%, so that they wither naturally under weak light conditions indoors, and the withering time is 6 hours;

[0056] (3) Kneading and cutting with rotor machine and C.T.C kneading and cutting machine

[0057] Knead the bars with a kneading machine for 30 minutes, deblock and sieve, and then enter the rotor kneading and cutting machine and the triple C.T.C kneading and cutting machine to knead and cut for 25 seconds;

[0058] (4) Stirring and fermentation

[0059] S...

Embodiment 2

[0063] (1) Selection and picking of fresh leaves

[0064] Select the fresh leaves of Qinglong big-leaf tea with one bud, one leaf and two leaves as the main fresh leaves and single leaves with the same tenderness, and the pair of clipped leaves as raw materials, and pick the fresh leaves of standard grade 3;

[0065] (2) Lay it flat on the ground for natural withering under indoor weak light conditions

[0066] Spread the picked fresh leaves on the ground with a leaf thickness of 13 cm, and control the moisture content of the withered leaves to 69%, so that they wither naturally under low light conditions indoors, and the withering time is 7 hours;

[0067] (3) Kneading and cutting with rotor machine and C.T.C kneading and cutting machine

[0068] Knead the strips with a kneading machine for 35 minutes, deblock and sieve, and then enter the combination of the rotor kneading and cutting machine and the triple C.T.C kneading and cutting machine for 28 seconds;

[0069] (4) Sti...

Embodiment 3

[0074] (1) Selection and picking of fresh leaves

[0075] Select the fresh leaves of Qinglong big-leaf tea with one bud, one leaf and two leaves as the main fresh leaves, and single leaves with the same tenderness, as raw materials, and pick the fresh leaves of standard grade 2;

[0076] (2) Lay it flat on the ground for natural withering under indoor weak light conditions

[0077] The picked fresh leaves are spread flat on the ground, the thickness of the spreading leaves is 20cm, and the moisture content of the withered leaves is controlled at 70%, so that they are naturally withered under low light conditions indoors, and the withering time is 8 hours;

[0078] (3) Kneading and cutting with rotor machine and C.T.C kneading and cutting machine

[0079] Knead the strips with a kneading machine for 40 minutes, deblock and sieve, and then enter the rotor kneading and cutting machine and the triple C.T.C kneading and cutting machine to knead and cut for 30 seconds;

[0080] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com