Oil-bath type reactor used for preparing NMP

A technology of reactor and oil bath, which is applied in the field of NMP preparation, can solve the problems of unstable parameters such as bed temperature, uneven heating of materials, and affecting reaction conversion rate, etc., and achieves a compact structure, increased space, and small footprint. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

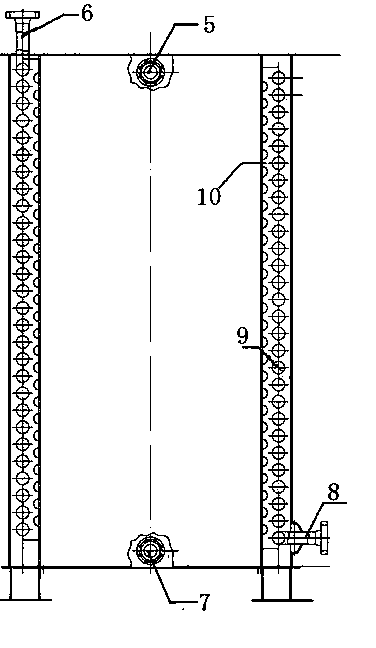

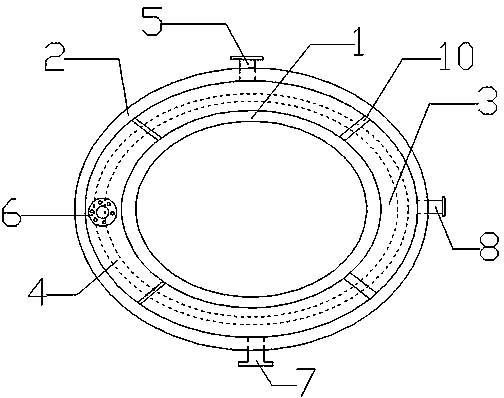

[0022] An oil bath reactor for preparing NMP, the reactor is a hollow cylinder, and a hollow interlayer 3 is formed between the inner wall 1 and the outer wall 2 of the reactor; the interlayer 3 has a built-in vertical coil structure reaction bed 4; The upper part of the reactor is provided with a heat transfer oil outlet 5 communicated with the interlayer 3 and a material inlet 6 communicated with the reaction bed 4; Material outlet 8; the reactor is connected with a control system.

[0023] The reaction bed 4 of the vertical coil structure is composed of a spiral material coil 9 .

[0024] The interlayer 3 is provided with a supporting structure.

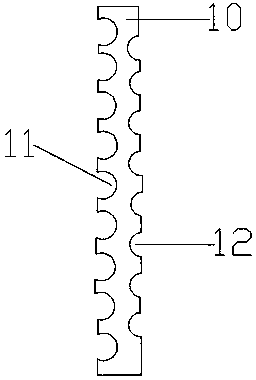

[0025] The support structure is a coil support plate 10, and the coil support plate 10 cooperates with the material coil 9 of the reaction bed.

[0026] One side of the coil support plate 10 is provided with a plurality of support holes 11 corresponding to the material coil 9 , and the other side is provided with a plurality of ...

Embodiment 2

[0033] An oil bath reactor for preparing NMP, the reactor is a hollow cylinder, and a hollow interlayer 3 is formed between the inner wall 1 and the outer wall 2 of the reactor; the interlayer 3 has a built-in vertical coil structure reaction bed 4; The upper part of the reactor is provided with a heat transfer oil outlet 5 communicated with the interlayer 3 and a material inlet 6 communicated with the reaction bed 4; Material outlet 8; the reactor is connected with a control system.

[0034] The reaction bed 4 of the vertical coil structure is composed of a spiral material coil 9 .

[0035] The interlayer 3 is provided with a supporting structure.

[0036] The support structure is a coil support plate 10, and the coil support plate 10 is matched with the material coil 9 of the reaction bed.

[0037] One side of the coil support plate 10 is provided with a plurality of support holes 11 corresponding to the material coil 9 , and the other side is provided with a plurality of ...

Embodiment 3

[0044] An oil bath reactor for preparing NMP, the reactor is a hollow cylinder, and a hollow interlayer 3 is formed between the inner wall 1 and the outer wall 2 of the reactor; the interlayer 3 has a built-in vertical coil structure reaction bed 4; The upper part of the reactor is provided with a heat transfer oil outlet 5 communicated with the interlayer 3 and a material inlet 6 communicated with the reaction bed 4; Material outlet 8; the reactor is connected with a control system.

[0045] The reaction bed 4 of the vertical coil structure is composed of a spiral material coil 9 .

[0046] The interlayer 3 is provided with a supporting structure.

[0047]The support structure is a coil support plate 10, and the coil support plate 10 cooperates with the material coil 9 of the reaction bed.

[0048] One side of the coil support plate 10 is provided with a plurality of support holes 11 corresponding to the material coil 9 , and the other side is provided with a plurality of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com