High-speed numerically-controlled machine tool used for machining precision part

A technology for CNC machine tools and precision parts, which is applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc. It can solve the problems of low processing accuracy and product forming efficiency, weak bearing capacity, etc., and achieve high product forming rate and bearing capacity. Strong, improve the effect of product accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

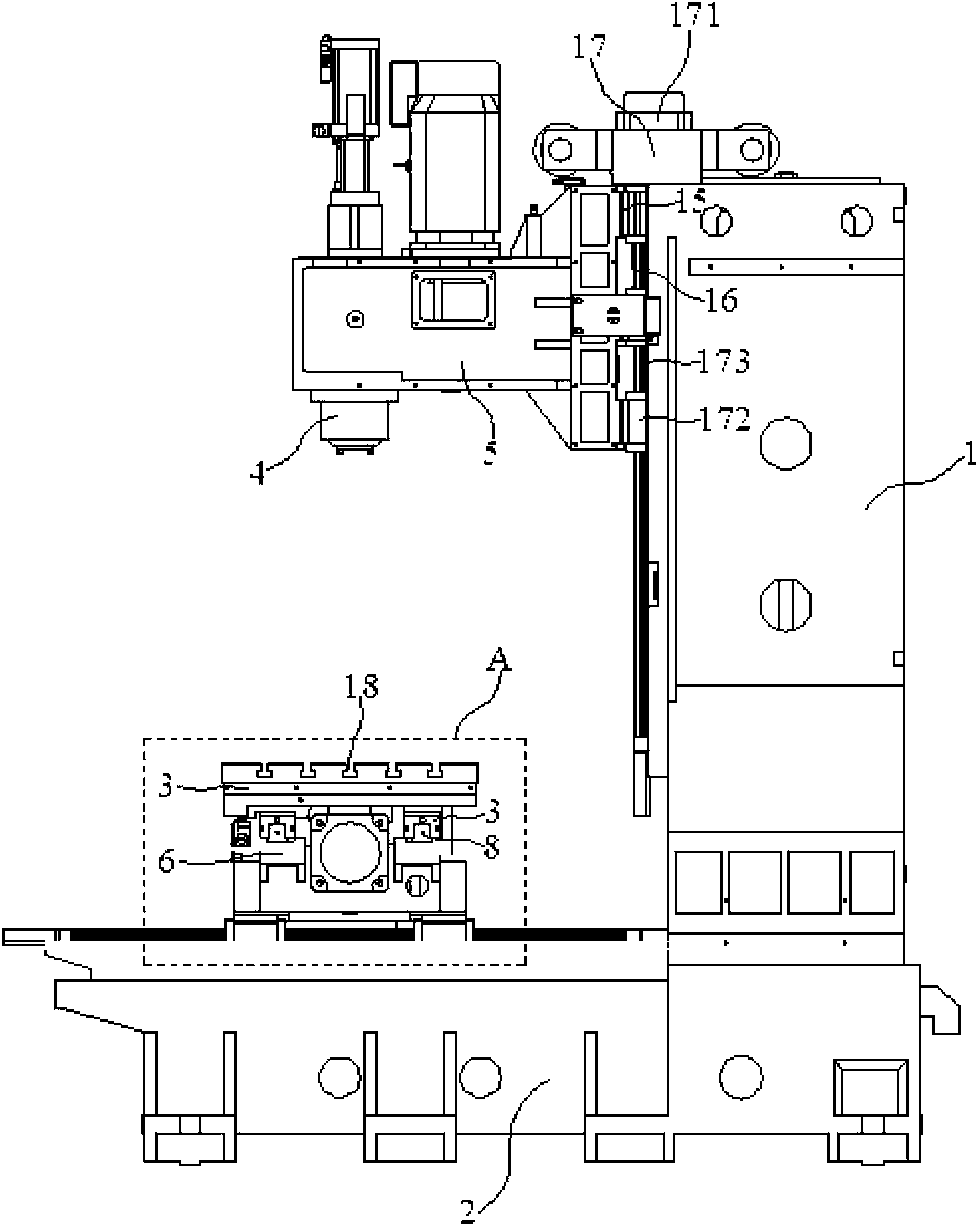

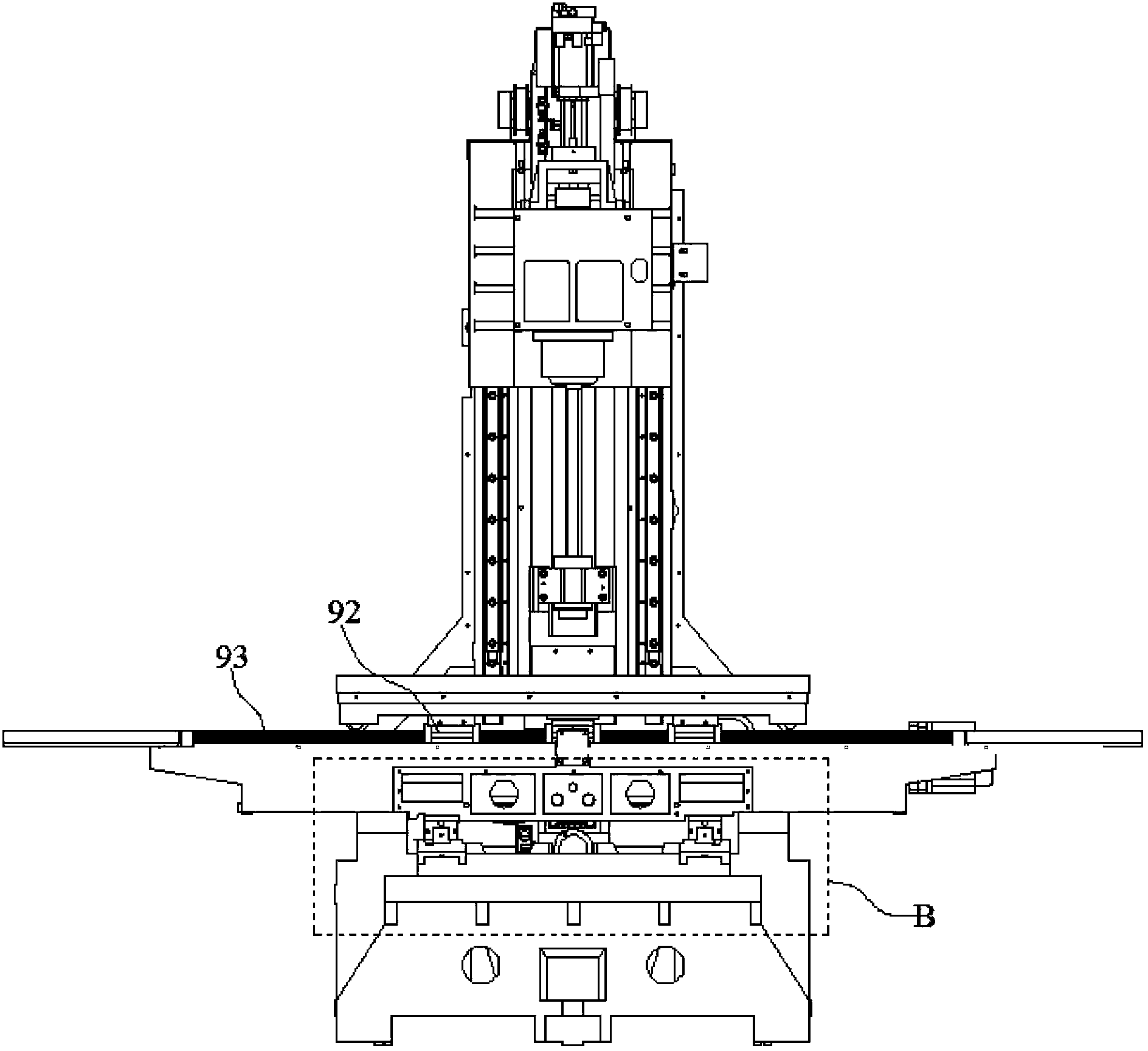

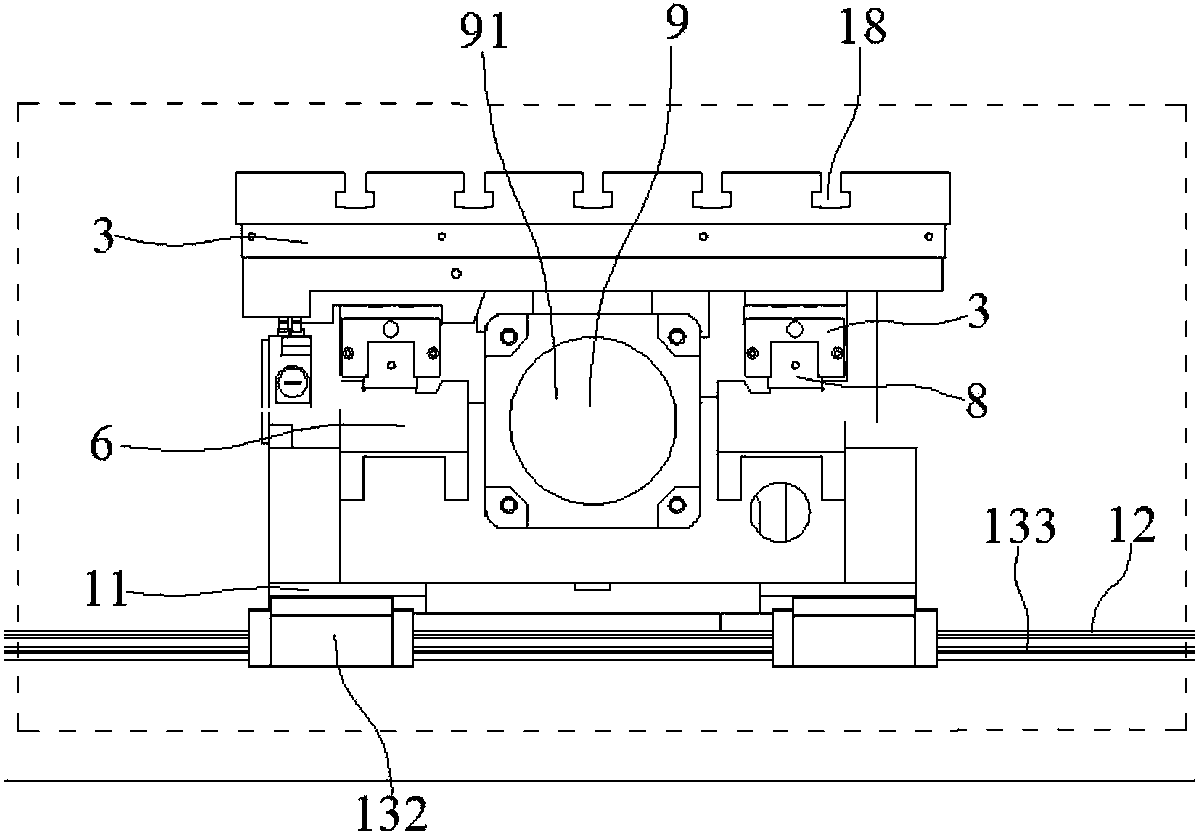

[0027] Embodiment: a kind of high-speed numerical control machine tool that is used for precision part processing, comprises column 1, base 2, workbench 3, machine head 5 that cutter 4 is installed, the first steel ring cover 19, the second steel ring cover 20, The third steel ring sleeve 26, the fourth steel steel ring sleeve 27 and the support plate 6 between the base 2 and the workbench 3, the column 1 is fixed on the upper surface of the base 2, and the machine head 5 is located on the column 1 The upper side and above the workbench 3;

[0028] At least two x-direction sliders 7 are fixed on the lower surface of the workbench 3 in parallel, and two x-direction rails 8 are fixed on the upper surface of the support plate 6 in parallel, and the x-direction rails 8 are embedded in the x-direction sliders 7, an x-direction drive mechanism 9 is located between two x-direction rails 8 and under the workbench 3. The x-direction drive mechanism 9 includes an x-direction motor 91, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com