Porous ceramic prepared by adopting different inorganic binders and preparation method thereof

An inorganic binder and porous ceramic technology, applied in the field of porous ceramics, can solve the problems of low porosity, poor purification effect, low recyclability, etc., and achieve the effect of high porosity and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

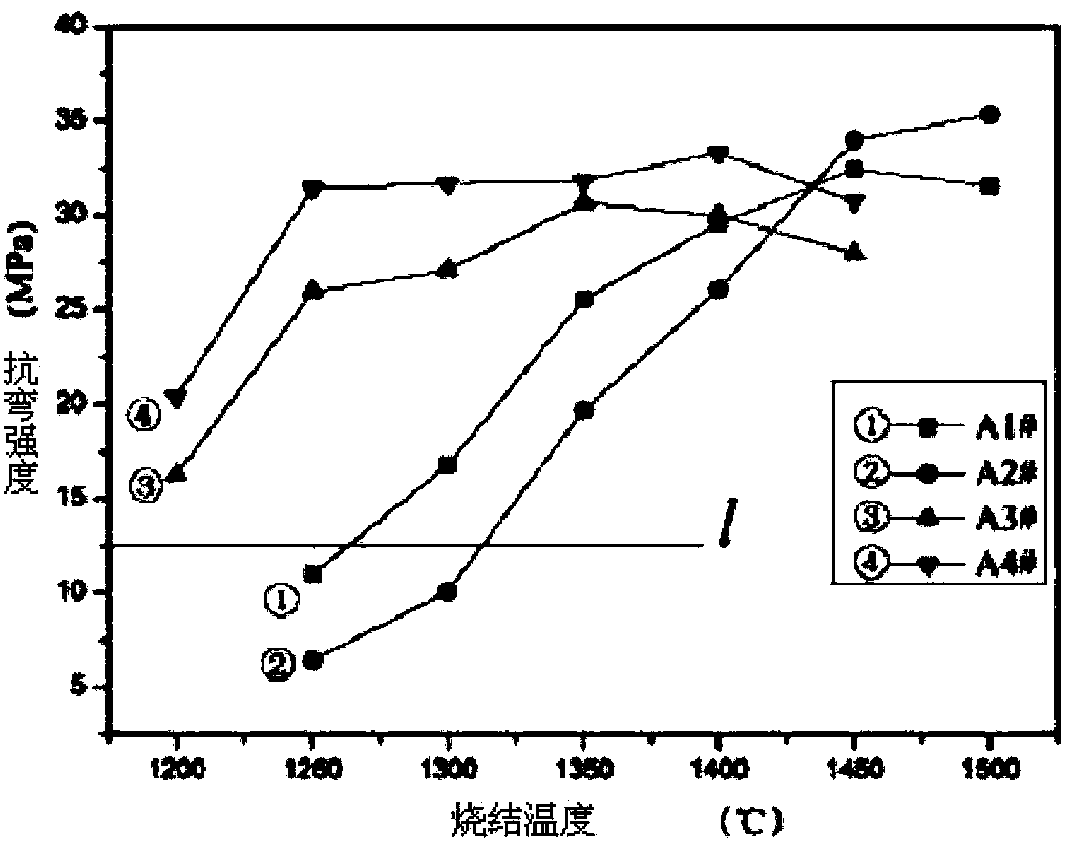

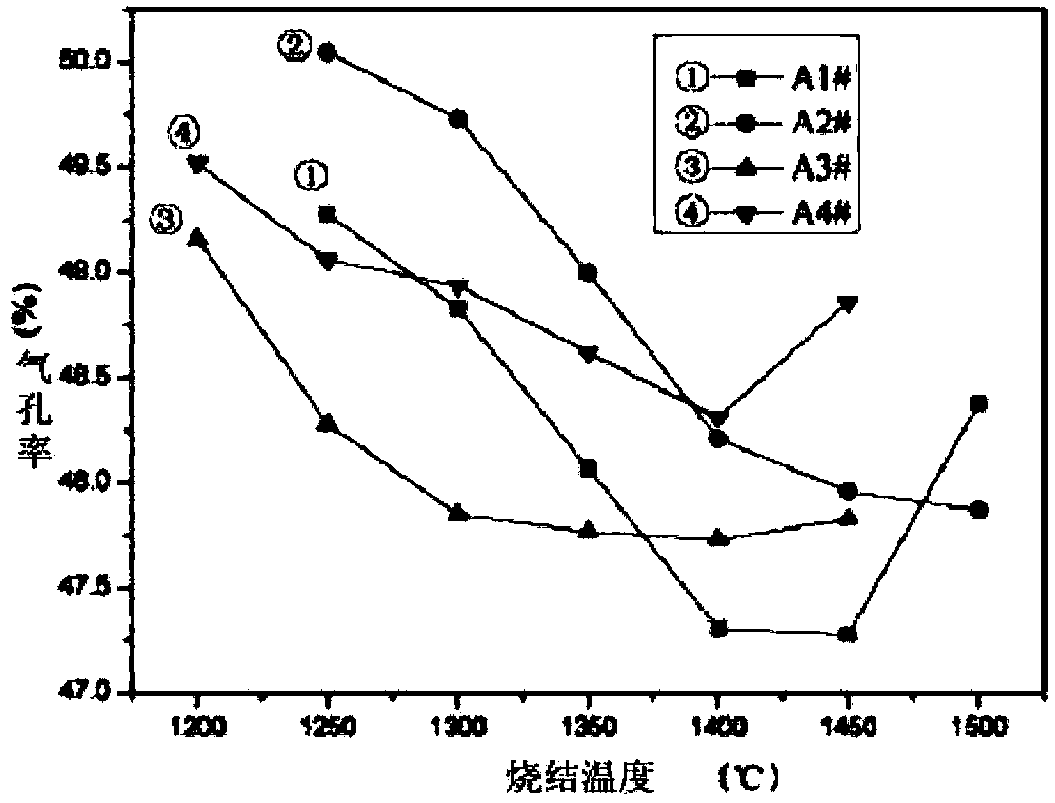

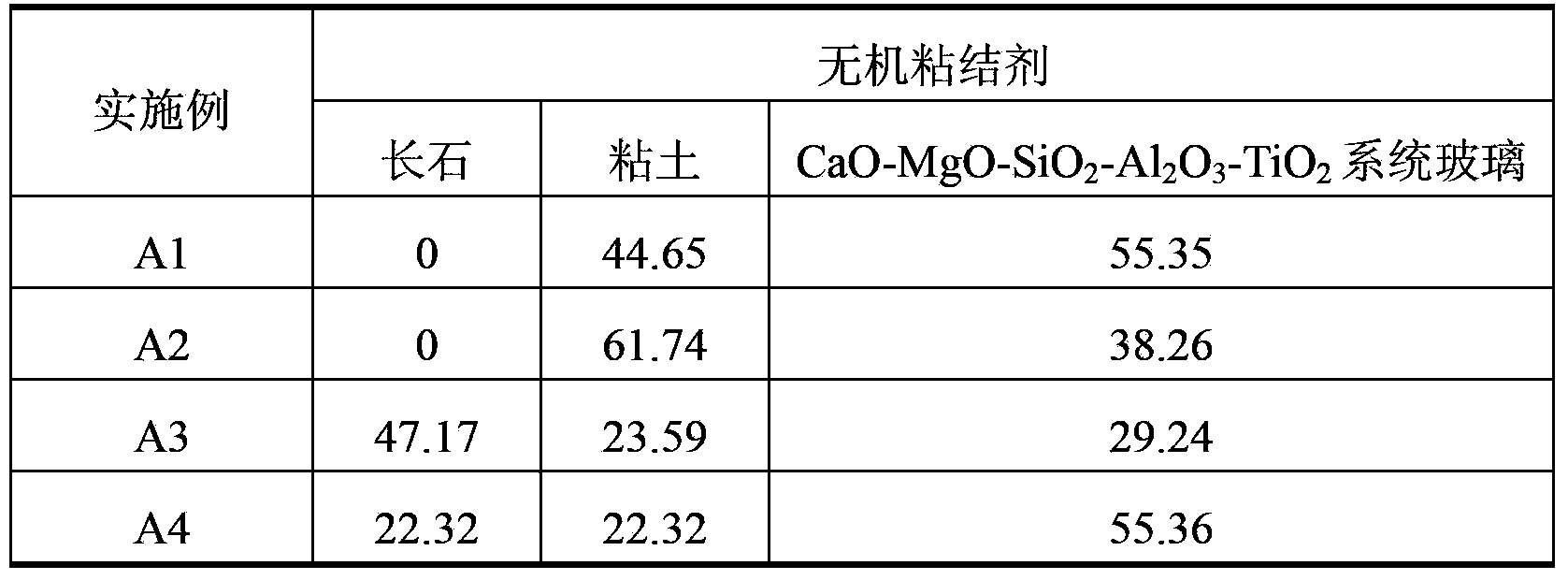

[0060] From Table 2 and figure 1 It can be seen that when the sintering temperature of the product is above 1300°C, the internal particles of the product are closely combined and have a certain strength. When the sintering temperature is 1350°C, the flexural strength of the sample can reach 25.57MPa, and reach the highest 32.45MPa at 1450°C; figure 2 It can be seen that when the sintering temperature of the product is 1200°C, the apparent porosity of the embodiment A1 reaches the highest 49.2%. As the sintering temperature increases, the apparent porosity does not decrease significantly. The apparent porosity is still as high as 48.12%.

Embodiment A2

[0062] From Table 2 and figure 1 It can be seen that the sintering temperature of the product is above 1350°C, and the internal particles of the product are closely combined. When the sintering temperature is 1400°C, the flexural strength can reach 26.08MPa, and when the sintering temperature is 1500°C, the flexural strength value can be as high as 35.36MPa ;Depend on figure 2 It can be seen that when the sintering temperature of the product is 1200 ° C, the apparent porosity of the sample of embodiment A2 reaches the highest 51.4%, and when the sintering temperature is 1350 ° C, the apparent porosity of the embodiment A2 is still as high as 49.18%.

Embodiment A3

[0064] From Table 2 and figure 1 It can be seen that when the sintering temperature of the product is 1200°C, it already has a certain strength and there is no particle drop phenomenon. When the sintering temperature is 1350°C, it reaches the highest strength of 30.68MPa. At the same time, the apparent porosity is 47.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com