Coating composition

A composition and coating technology, applied in the direction of conductive coatings, coatings, etc., can solve problems such as insufficient conductive primer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

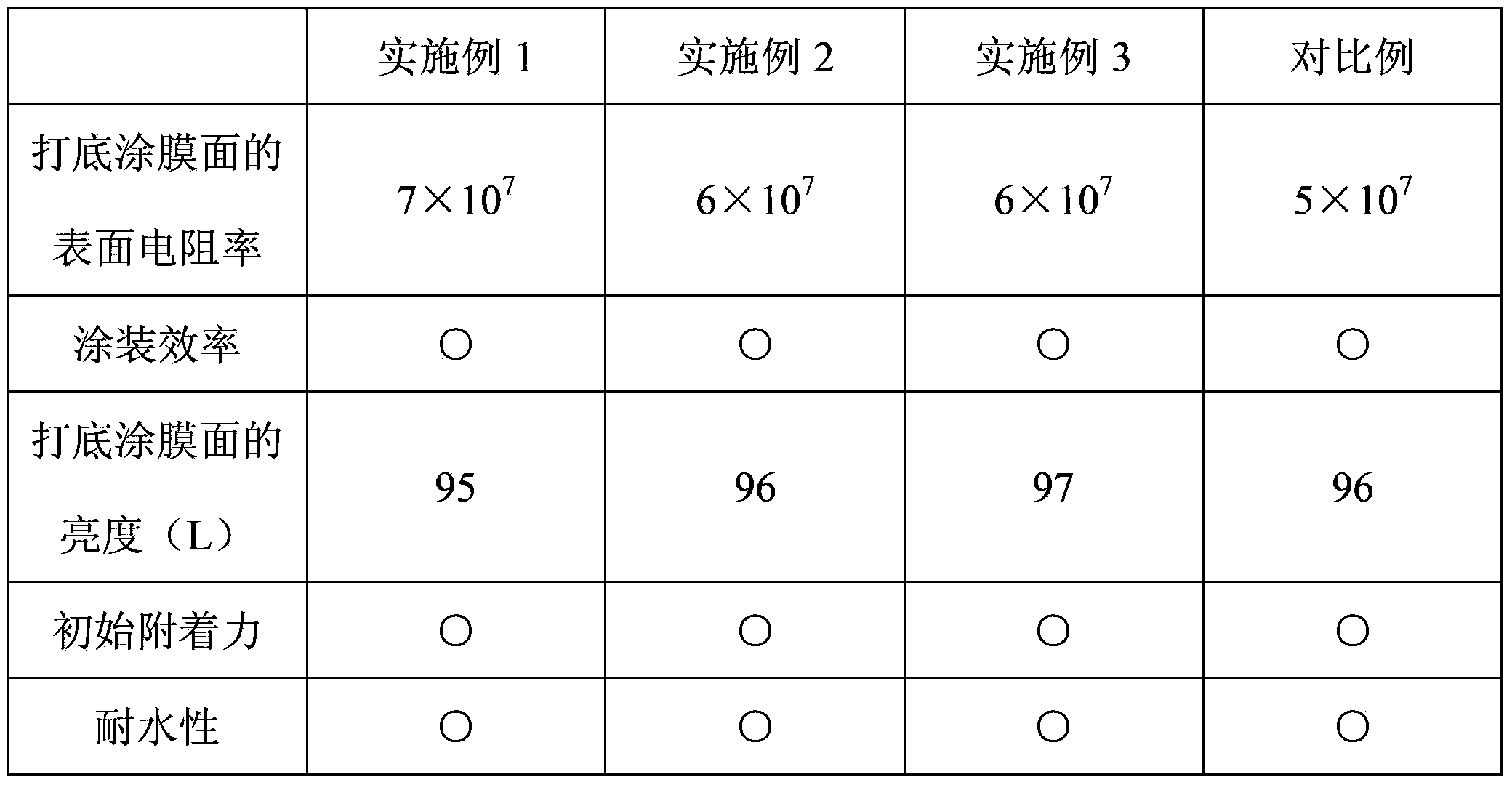

Examples

Embodiment 1

[0041] According to the conventional method, 30 parts of metallocene polyethylene (weight average molecular weight is about 60,000, molecular weight distribution index 3.0), 15 parts of 1,2-dimethylimidazolium tetrafluoroborate, 15 parts of polyacrylic acid resin, quaternary ammonium 2 parts of salt conductive agent, 5 parts of melamine resin, and 20 parts of red iron oxide were diluted with deionized water so that the solid content became 44%, thereby obtaining a conductive coating composition.

Embodiment 2

[0043] According to conventional methods, 40 parts of metallocene polypropylene (weight-average molecular weight of about 140,000, molecular weight distribution index of 1.5), 30 parts of 1-butyl-3-methylimidazolium hexafluorophosphate, 10 parts of polyacrylic acid resin, quaternary 1 part of ammonium salt conductive agent, 10 parts of hexamethylene diisocyanate, and 20 parts of red iron oxide were diluted with deionized water so that the solid content became 42%, thereby obtaining a conductive coating composition.

Embodiment 3

[0045] According to the conventional method, 60 parts of metallocene polypropylene (weight average molecular weight is about 100,000, molecular weight distribution index 2.0), 1 part of 1-hexyl-3-methylimidazolium tetrafluoroborate, 30 parts of polyacrylic acid resin, quaternary 5 parts of ammonium salt conductive agent, 25 parts of hexamethylene diisocyanate, and 5 parts of red iron oxide were diluted with deionized water so that the solid content became 42%, thereby obtaining a conductive coating composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com